12

SEASTAR Hydraulics

BATTERY

+

BATTERY

–

IGNITION

SIGNAL

+

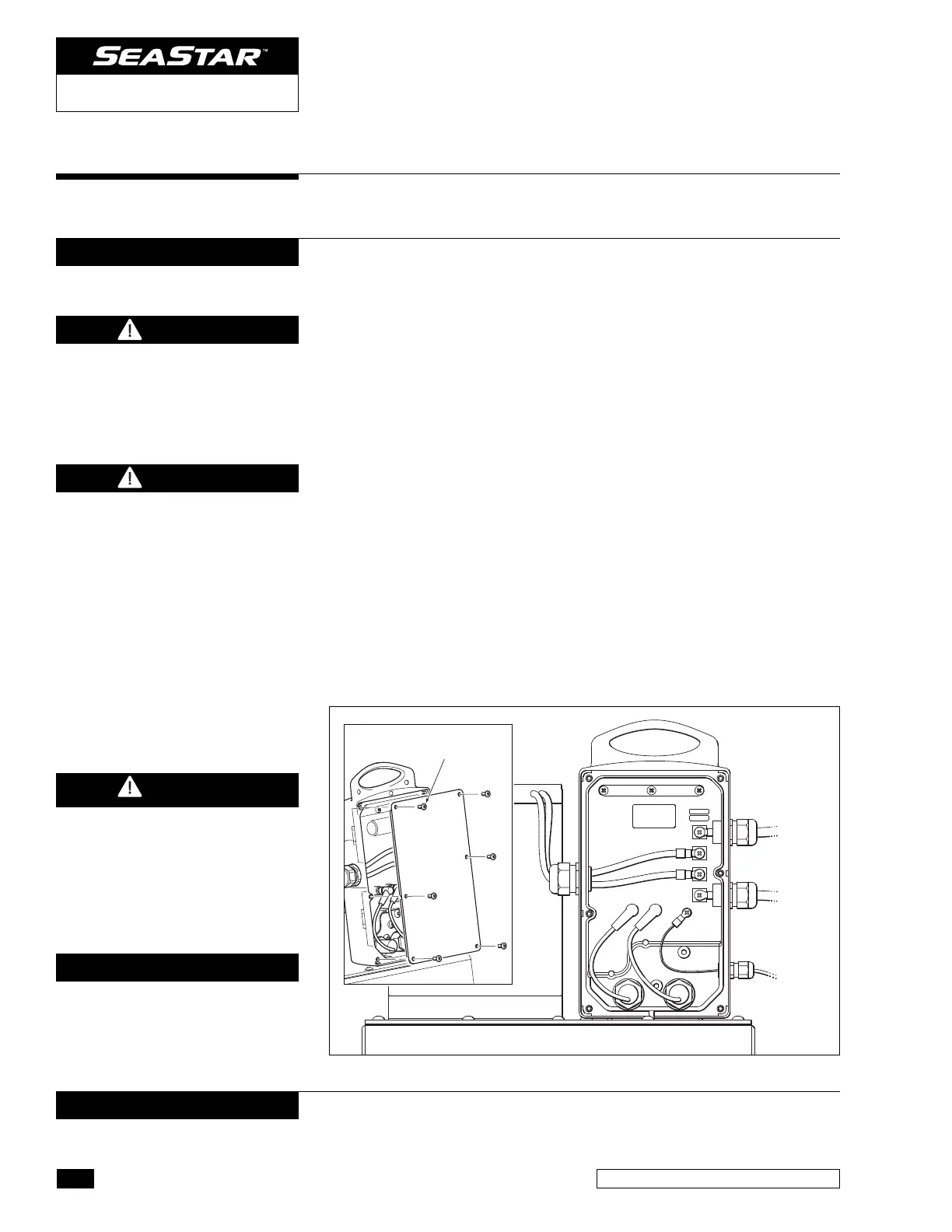

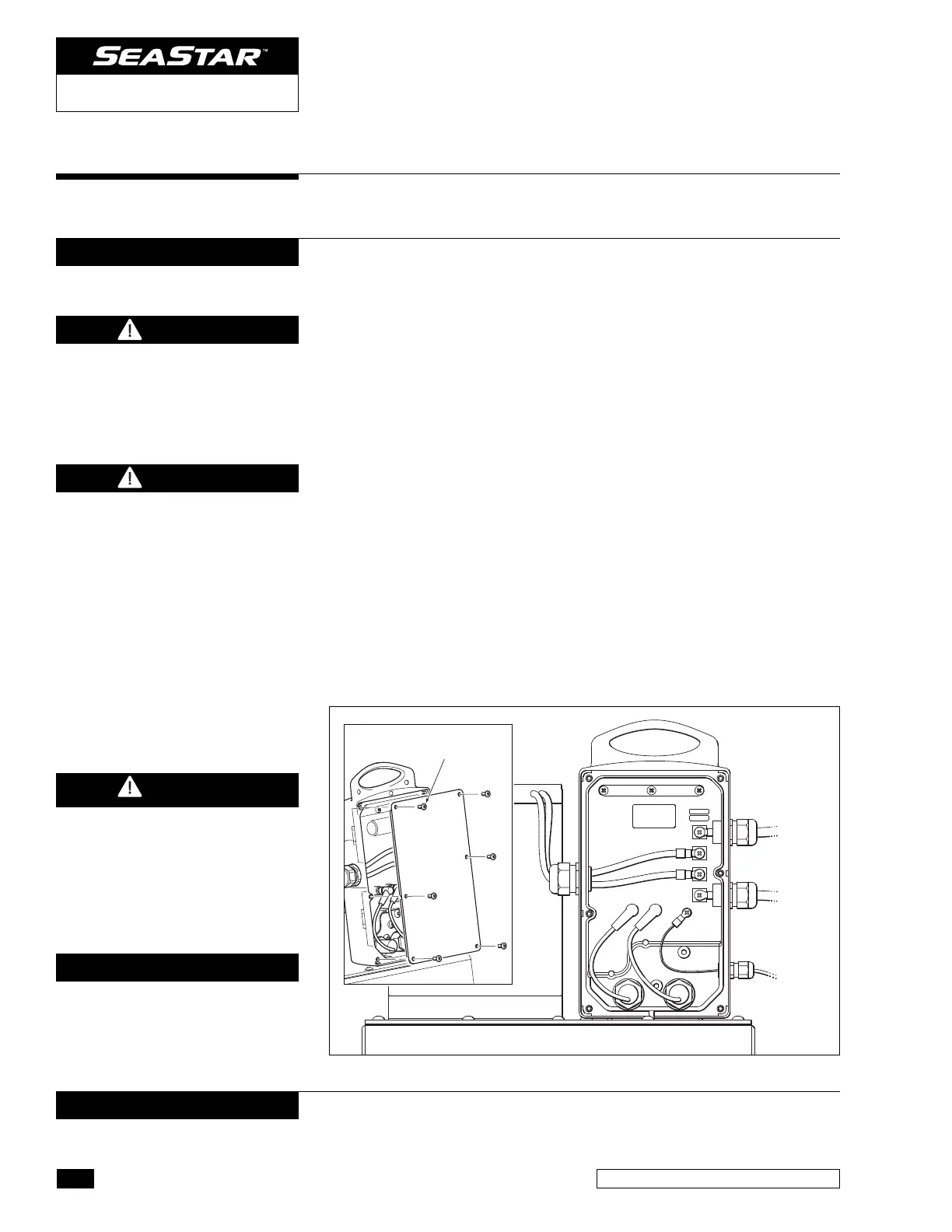

COVER SCRWS

PHILLIPS (6)

NOTICE

Step 2 Electrical Connections

Figure 11.

DC Power Unit Battery Connections

It is recommended that the DC Power unit be connected directly to

a main battery, or other on-board 24-volt power source rated for 90

amps peak using an appropriate fuse or breaker.

1 Remove electronics casing cover by removing the 6 Phillips head

screws. (Refer to Figure 11.)

2 Insert positive batter y lead through the upper strain relief fitting

on the electronics box. (Refer to Figure 11.)

3 Remove the #10 Phillips head screw from the top-most terminal

inside the electronics enclosure. Securely fasten the positive

lead with ring connector to this terminal post, torque to 25in-lbs.

4 Insert negative batter y lead through the lower strain relief fitting

on the electronics box. (Refer to Figure 11.)

5

Remove the #10 Phillips head screw from the bottom-most terminal

inside the electronics enclosure. Securely fasten the negative

lead with ring connector to this terminal post, torque to 25in-lbs.

6 Using a crescent wrench, tighten the strain relief nuts until the

rubber sleeves form a seal with the wires. DO NOT OVER TIGHTEN.

7 Connect the other ends of your battery leads to your breaker

box, battery, or other 24V power source rated for a minimum of

90A peak current.

8

Leave the electronics cover off for the moment, you are not finished.

To avoid risk of fire, ensure that

the area in which any electrical

connection is being made is

vented and free of any fumes

that may cause fire or explosion.

WARNING

DO NOT REVERSE POLARITY.

The use of color coded (Red/

Black) wiring is highly recom-

mended to avoid reversing

polarity. Failure to comply may

result in damage to the unit.

WARNING

To avoid fire and/or poor

steering performance, ALL

electrical connections and

cable MUST comply with ABYC

wiring standards, be rated for

105 degrees C, and compliant

with SAE J1128. Battery leads

must be a MINIMUM of 6AWG

and a MAXIMUM of 30ft in

length, with an appropriate

fuse or breaker for fire

protection. If your application

requires longer battery leads,

please consult factory.

WARNING

NOTICE

It is recommended that ring-type

crimp connections are used at

each

end of the battery harness.

Use the correct ring terminal for the wire

gauge, and the appropriate crimping pliers.

2.1

DC POWER STEERING UNIT

NOTICE

Battery connections inside the

electrical

box should be made

using ring terminals sized for a

#10 stud.

Loading...

Loading...