Operating Manual

MG1/dw-00 page 11 / 20

en MG1/dw-00 / June 13, 2006 Rev. 10.1

Description and function

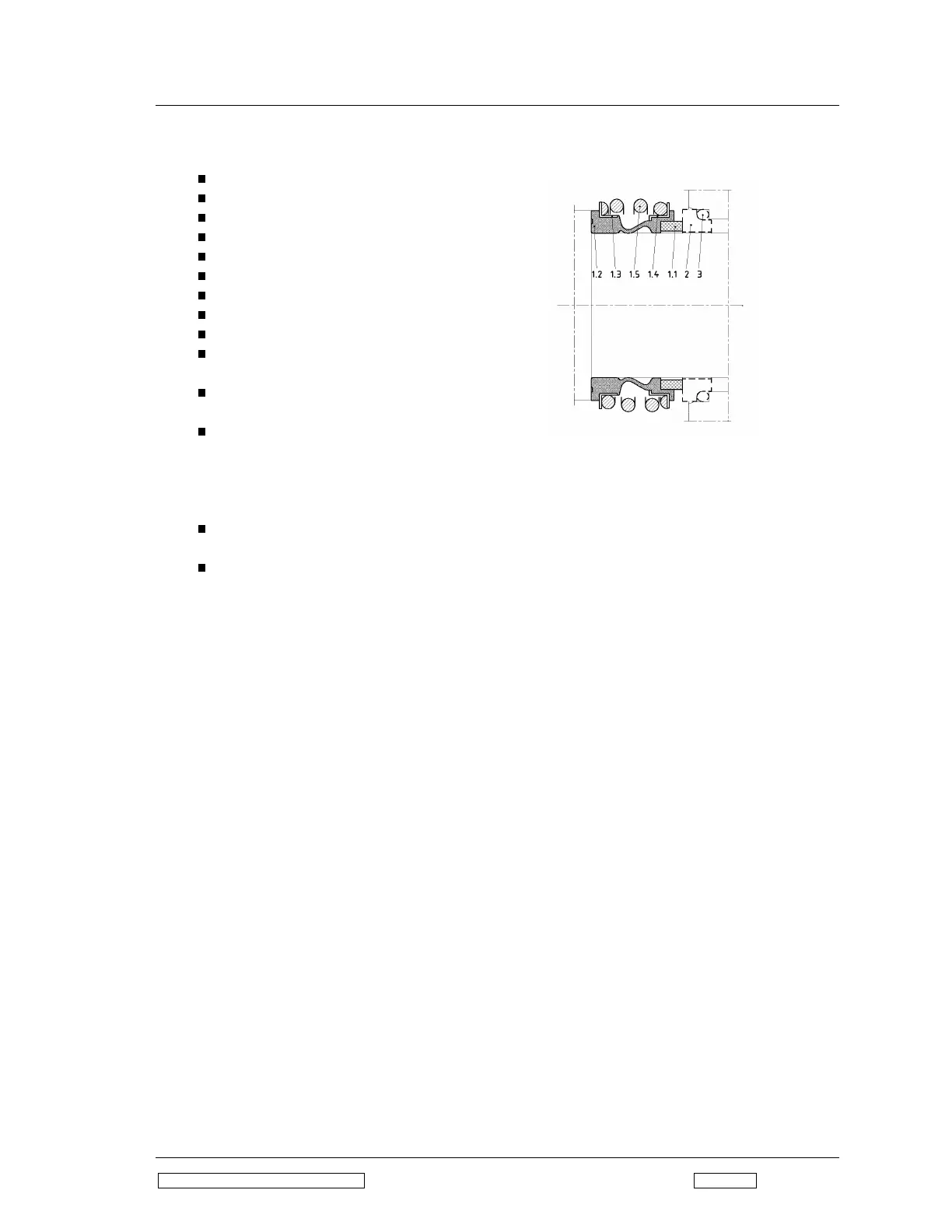

single seal

unbalanced

bi-directional

stationary seat (2)

o-ring (3)

rotating seal face (1.1)

elastomeric bellow (1.2)

cylindrical single spring (1.5)

no glued joints

materials of the sliding parts

replaceable

for media containing solids (e.g.

sewage applications)

rotating, torsion-free elastomeric

bellows serving as

! face housing

! secondary sealing element

! drive collar

torque transmission from the seal face by means of "L"-rings and a rotating,

cylindrical single spring

axial movability

d

w

: 10 … 12 mm ±0,5 mm

d

w

: 14 … 18 mm ±1,0 mm

d

w

: 20 … 26 mm ±1,5 mm

d

w

: 28 … 100 mm ±2,0 mm

Required space, connecting dimensions

The required mounting space for the mechanical seal is decisive for the design of the

housing parts by the machine manufacturer. The connecting dimensions have to be

checked by the machine manufacturer by means of the BURGMANN drawing before

mounting the mechanical seal.

Supply of M.S.

The mechanical seal has to be constantly wetted by liquid medium. The medium to

be sealed must not damage the M.S. neither chemically (e.g. corrosion,

embrittlement) nor physically (e.g. erosion, abrasion).

For a safe operation of the mechanical seal we recommend to apply at inboard the

most suitable type of circulation described in API 610 / 682. This measure protects

the seal cavity from deposition of solids.

To operate multiple seals special supply systems are required. Please contact

BURGMANN.

Loading...

Loading...