20

Problem Possible Cause Solution

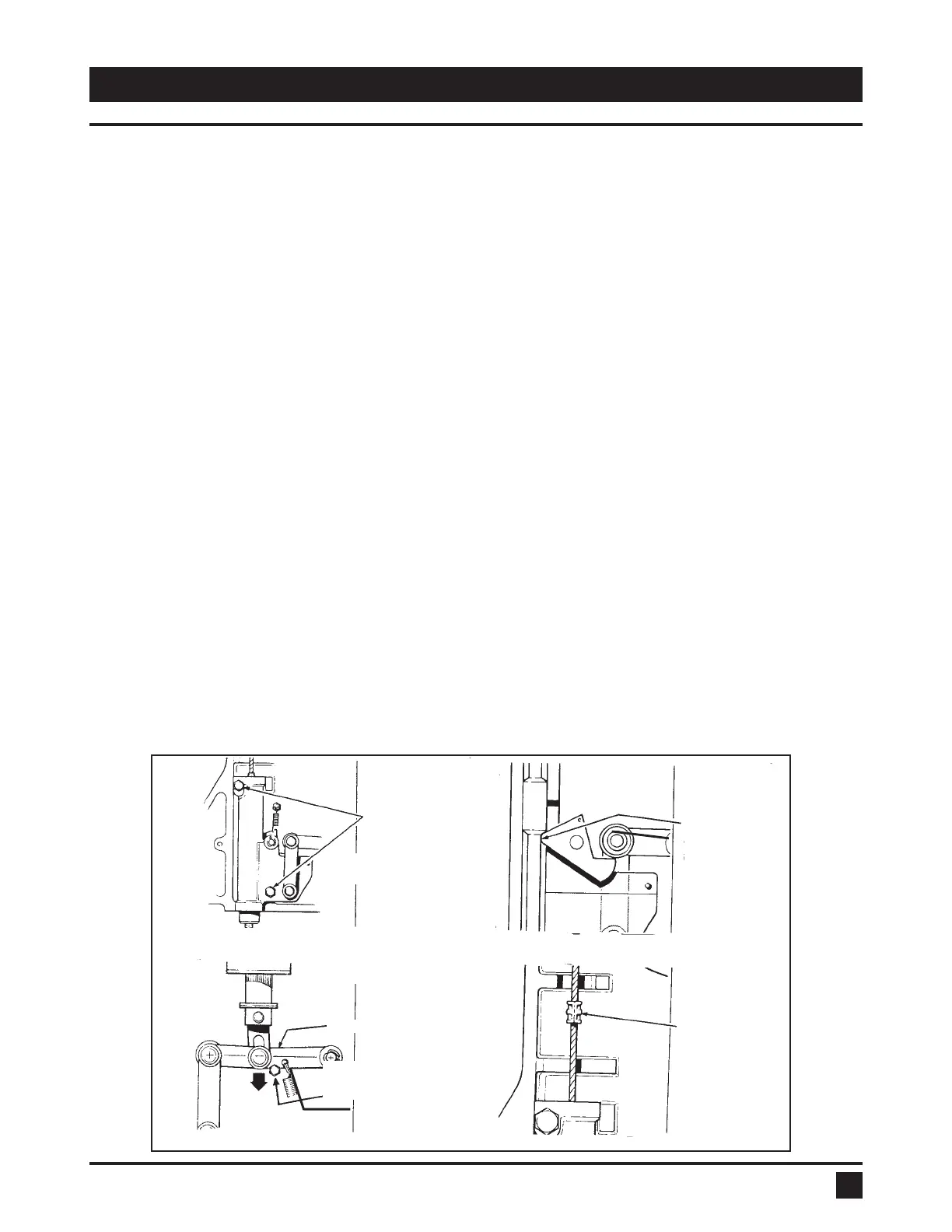

Head releases dump Loose trip block bolts Tighten trip block bolts. See Fig. 19.

valve prematurely

Links are above center Check that links are below center

line of clevis pins. Adjust links. See Fig. 20.

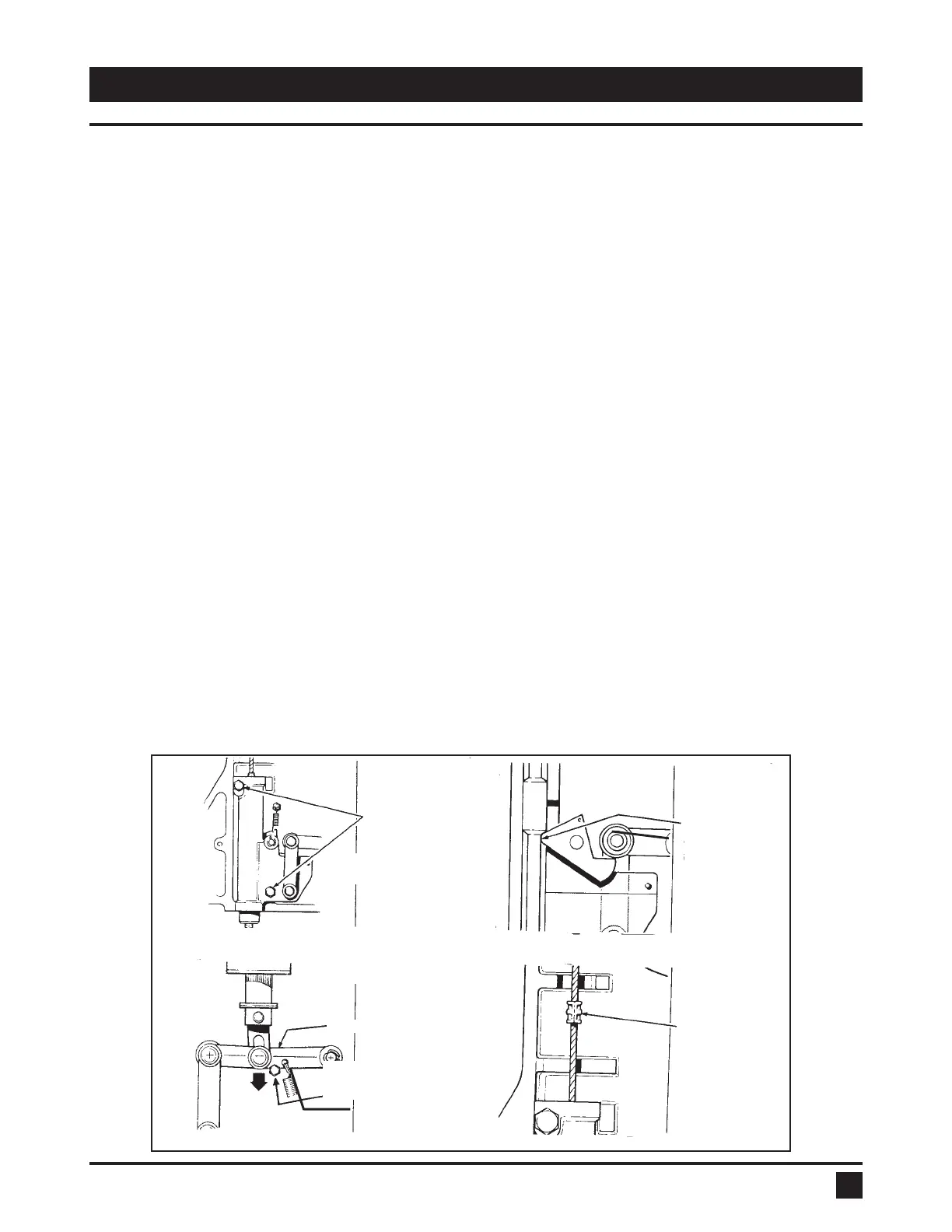

Worn catch at point Check the catch point for wear at the

bullet. Replace catch. See Fig. 21. See

Section 13.3 for catch replacement

procedure.

Trip line jams on

returning

Trip line doesn’t

return

12. GENERAL TROUBLE SHOOTING

Trip line sleeves are

fouling cast lugs on

head

Pull the trip line completely out. Check that

the swaged sleeves at the end of the trip

line are not fouling the cast guide lugs on

the head and cover. Round the end of the

swage sleeves with a file. See Fig. 22. If

necessary the lower set of cast lugs (closest

to the trip block) on the head act as a safety

keeper to prevent a trip line broken at the

top end from causing a tail rotor strike. The

swage blocks should not pass between

them.

Check for a broken spring in the reel. A

broken spring is indicated if the tension on

the reel doesn’t increase as the reel is

wound, or if the tension increases in jerks

or the spring seems to “slip” inside the reel.

See Section 13.2 for reel replacement

procedure.

Broken spring in reel

CHECK

FOR

LOOSE

TRIP

BLOCK

BOLTS

Fig 19

CHECK

LINKS ARE

BELOW

CENTER

LINE OF

CLEVIS PINS

CHECK

LINKS DO

NOT CATCH

HEAD OF

BOLT

Fig 20

CHECK

CATCH

FOR

WEAR

AT

POINT

Fig 21

CHECK

SWAGED

SLEEVE FOR

FOULING ON

CAST LUGS

Fig 22

Loading...

Loading...