2.

THE

POSITION

OF

THE

NEEDLE

AND

NEEDLE

HOLE

OF

THE

FEEDER

To adjust this, turn the handwheel to raise the needle

bar

to its highest

point

and

put

correct

needles.

Turning the hand wheel to lower slowly the needle bar, check whether

the

needle

descends

to

the

center

of

the

needle

hole

of

the

feeder

or

not.

If

the

needle

does

not

enter

into

the

center

of

the

hole,

remove

the

side

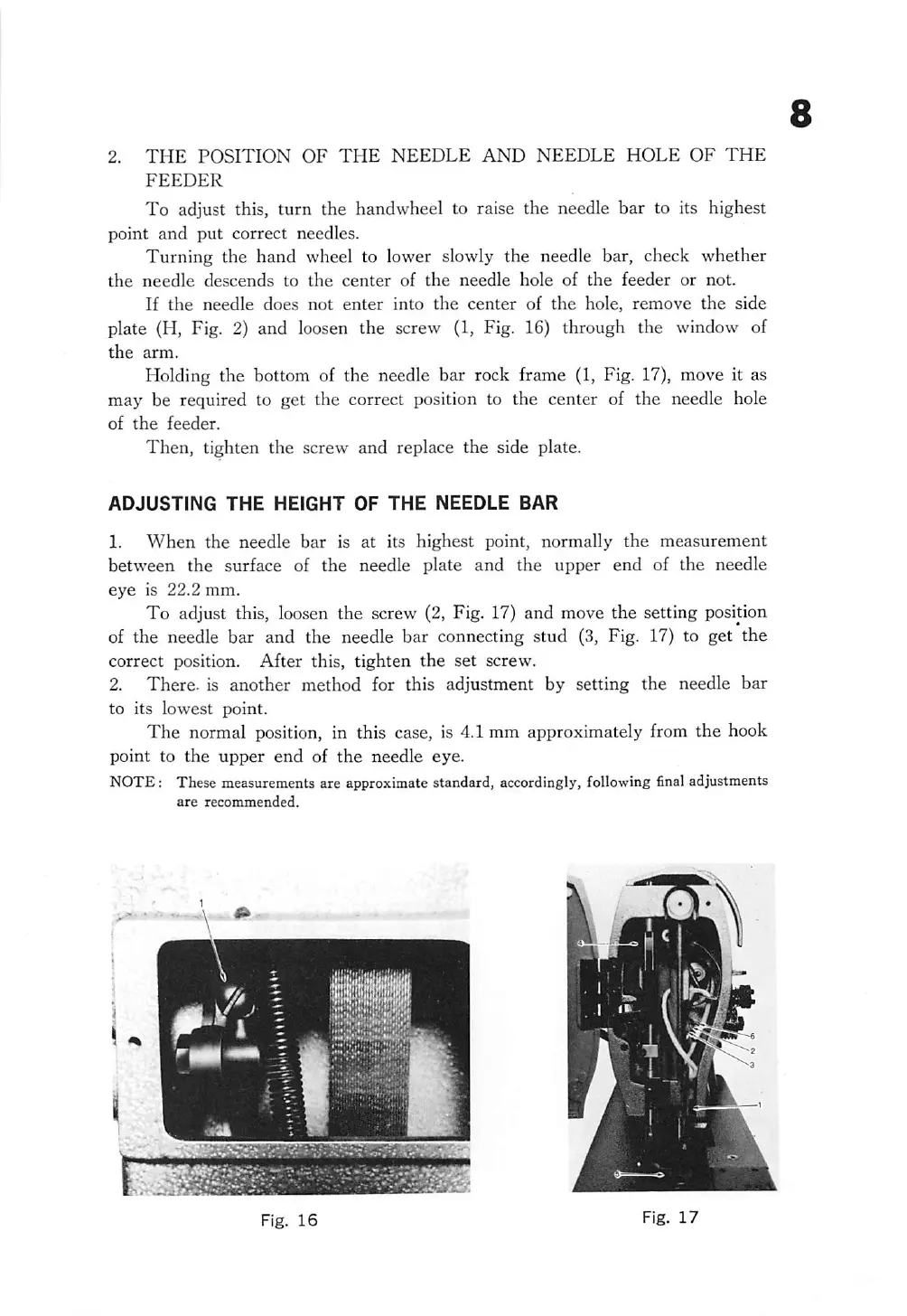

plate (H, Fig. 2) and loosen

the

screw (1, Fig. 16) through the window of

the

arm.

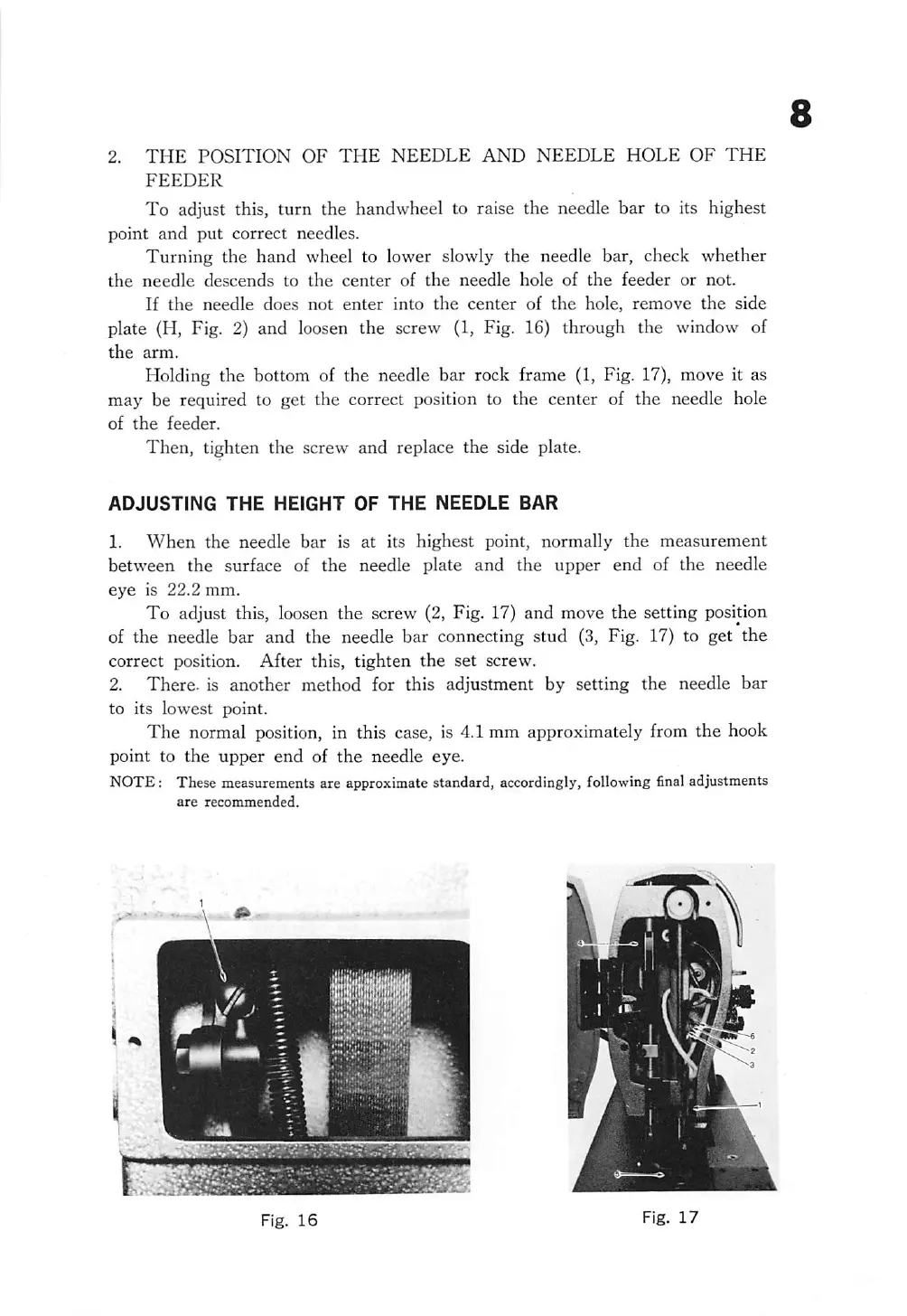

Holding the bottom of the needle bar rock frame (I, Fig. 17), move it as

may be required to get the correct position to the center of the needle hole

of

the

feeder.

Then,

tighten

the

screw

and

replace

the

side plate.

ADJUSTING

THE

HEIGHT

OF

THE

NEEDLE

BAR

1.

When

the

needle

bar

is at its highest point, normally

the

measurement

between

the

surface of

the

needle plate

and

the

upper

end

of

the

needle

eye

is

22.2

mm.

To

adjust this, loosen

the

screw (2, Fig. 17)

and

move

the

setting position

of the needle

bar

and the needle

bar

connecting stud (3, Fig. 17) to get the

correct position.

After

this, tighten

the

set screw.

2. There, is another method for this adjustment by setting the needle

bar

to its

lowest

point.

The normal position, in this case, is 4.1 mm approximately from the hook

point

to

the

upper

end

of

the

needle

eye.

NOTE:

These measurements are approximate standard, accordingly, following finaladjustments

are

recommended.

Bb

Fig.

16

Fig.

17

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...