TIMING

BETWEEN

THE

HOOK

AND

NEEDLE

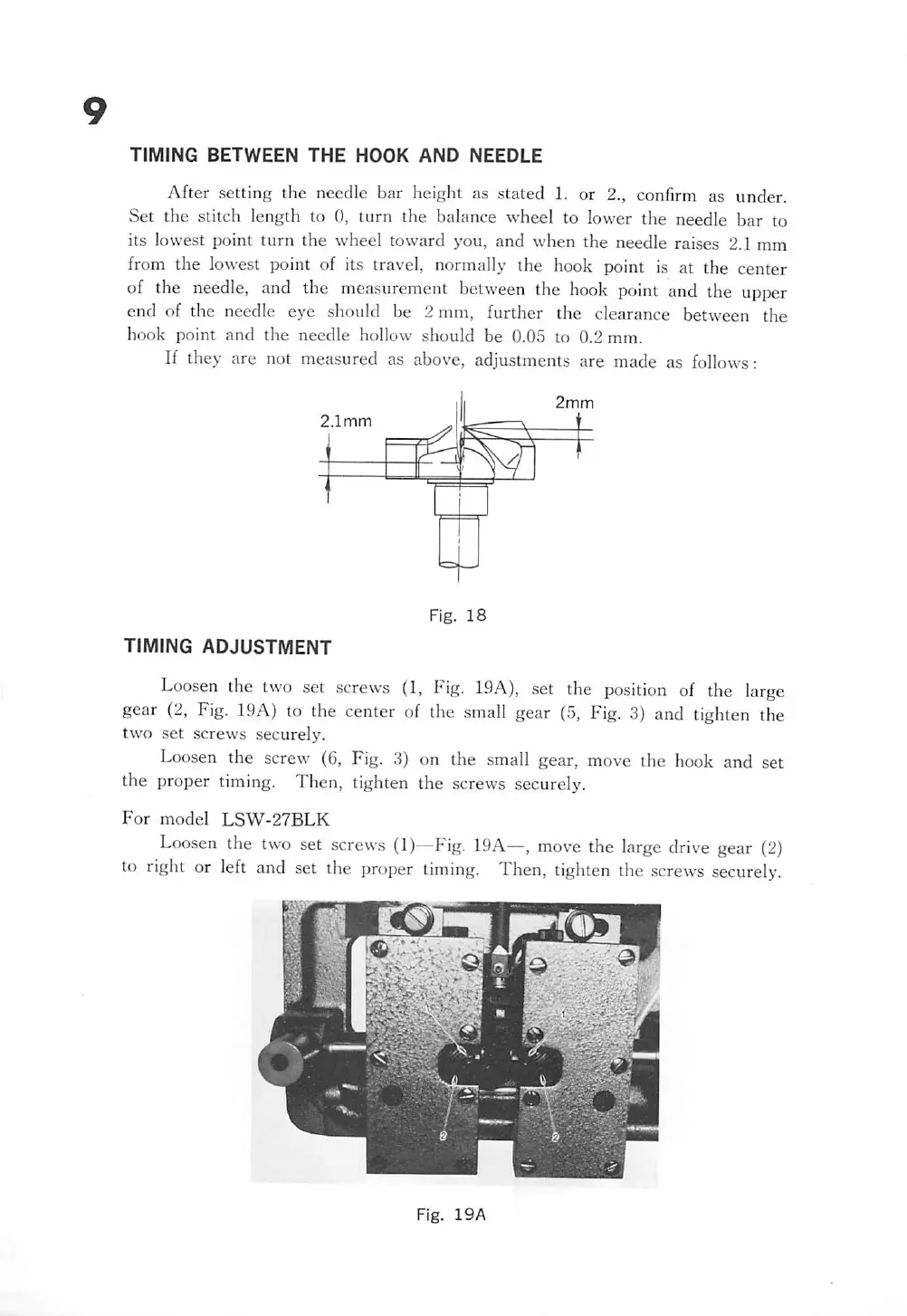

After setting the needle bar height as stated 1. or 2., confirm as under.

Set the stitch length to 0, turn the balance wheel to lower the needle bar to

its lowest point turn the wheel toward you, and when the needle raises 2.1 mm

from the lowest point of its travel, normally the hook point is at the center

of the

needle,

and

the

measurement

between

the

hook

point

and

the

upper

end of the needle eye should be 2 mm, further the clearance between the

hook

point

and

the

needle

hollow

should

be

0.05

to 0.2

mm.

If they are not measured as above, adjustments are made as follows:

2.1mm

Fig.

18

TIMING

ADJUSTMENT

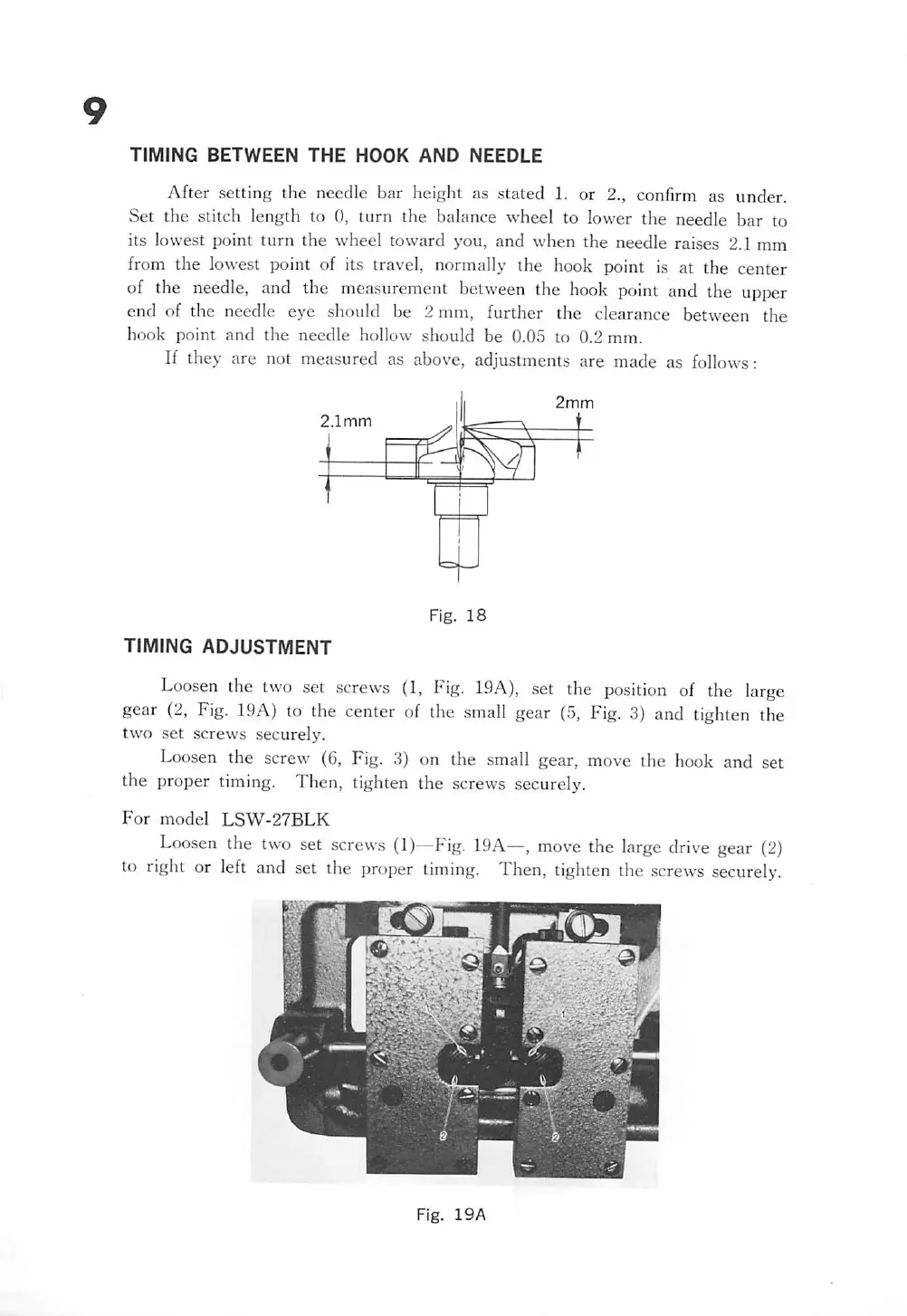

Loosen

the

two

set

screws

{1,

Fig.

19A),

set

the

position

of

the

large

gear

(2,

Fig,

19A)

to the

center

of the

small

gear

(5,

Fig.

3)

and

tighten

the

two

set

screws

securely.

Loosen

the screw (6, Fig. 3) on the small gear, move the

hook

and set

the

proper

timing.

Then,

tighten

the

screws

securely.

For

model

LSW-27BLK

Loosen

the

two

set

screws

(1)—Fig.

19A—,

move

the

large

drive

gear

(2)

to

right

or

left

and

set

the

proper

timing.

Then,

tighten

the

screws

securely.

Fig.

19A

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...