19

III.

Turn

hook

only

so

that

hook

point

comes

to

the

needle

as (7)—Fig. 29.

IV.

To

correctly adjust the position of

the

needles (1) relative to hook points

(2), remove the needle clamps (3) from their respective needle bars by

removing needle clamp

set

screw

(4).

Upon

removing

the

needle clamps,

needle clamp adjusting screw (5) become accessible.

Turn

adjusting

screw (5) either in or out to obtain the 4.4 mm (11/64") in LSW-27BLK

(4.1mm (5/32") in LTW-27BK) distance between the eye of the needle

when at its lowest position and

the

hook point (Fig. 29) after the needle

clamps with needles have been replaced on

the

needle bars.

Be sure

that

needle clamp adjusting screw (5) contacts

the

bottom

of needle

bar

plug (6) and tighten needle clamp set screws (4).

V.

Turn

hand

wheel toward you allowing needles to rise.

When

the

rotating

hook point crosses the centerline of the rising needle, it should be 2 mm

(5/64")

above the upper end of

the

eye of

the

needle. Adjust if

necessary. (Fig. 30)

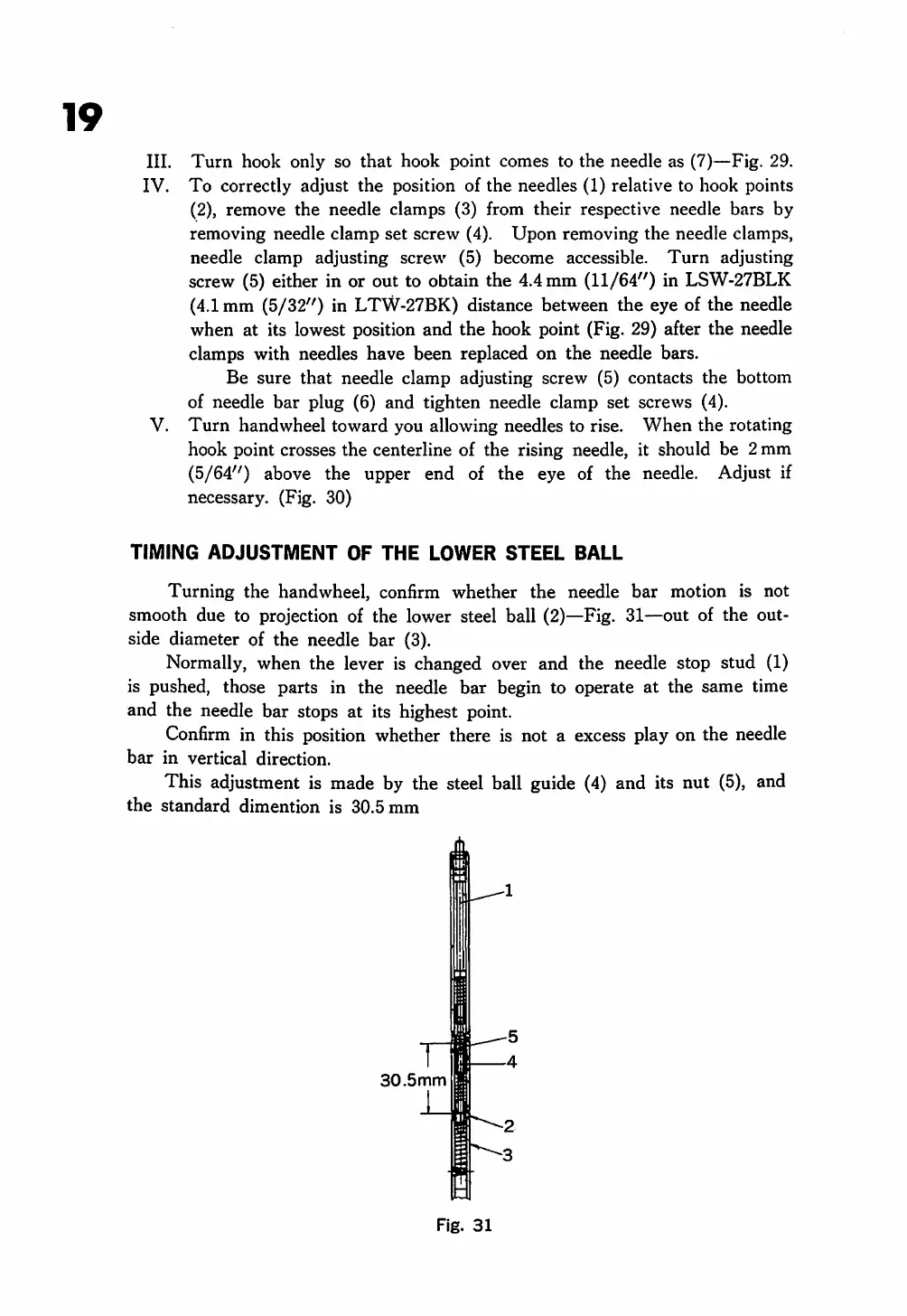

TIMING

ADJUSTMENT

OF

THE

LOWER

STEEL

BALL

Turning

the

hand

wheel, confirm whether

the

needle

bar

motion is not

smooth due to projection of the lower steel ball (2)—Fig. 31—out of the out

side diameter of the needle

bar

(3).

Normally, when the lever is changed over and the needle stop stud (1)

is pushed, those parts in the needle

bar

begin to operate at the same time

and the needle bar stops at its highest point.

Confirm in this position whether there is not a excess play on the needle

bar

in

vertical

direction.

This adjustment is made by the steel ball guide (4) and its nut (5), and

the

standard

dimention

is

30.5

mm

30.5mm

Fig.

31

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...