3-10 Overcurrent, Voltage, Synchronism Check, and Frequency Elements Date Code 20010307

SEL-351A Instruction Manual

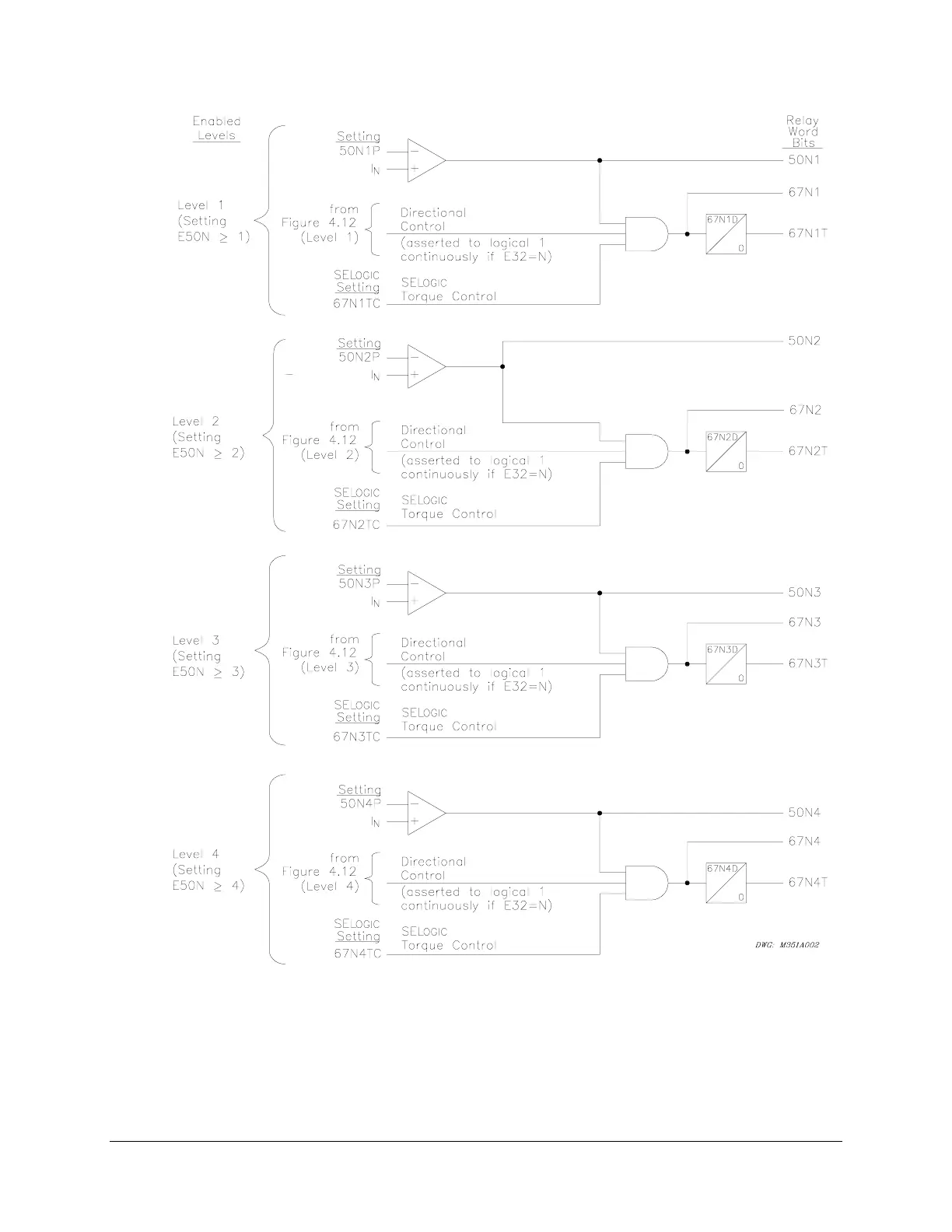

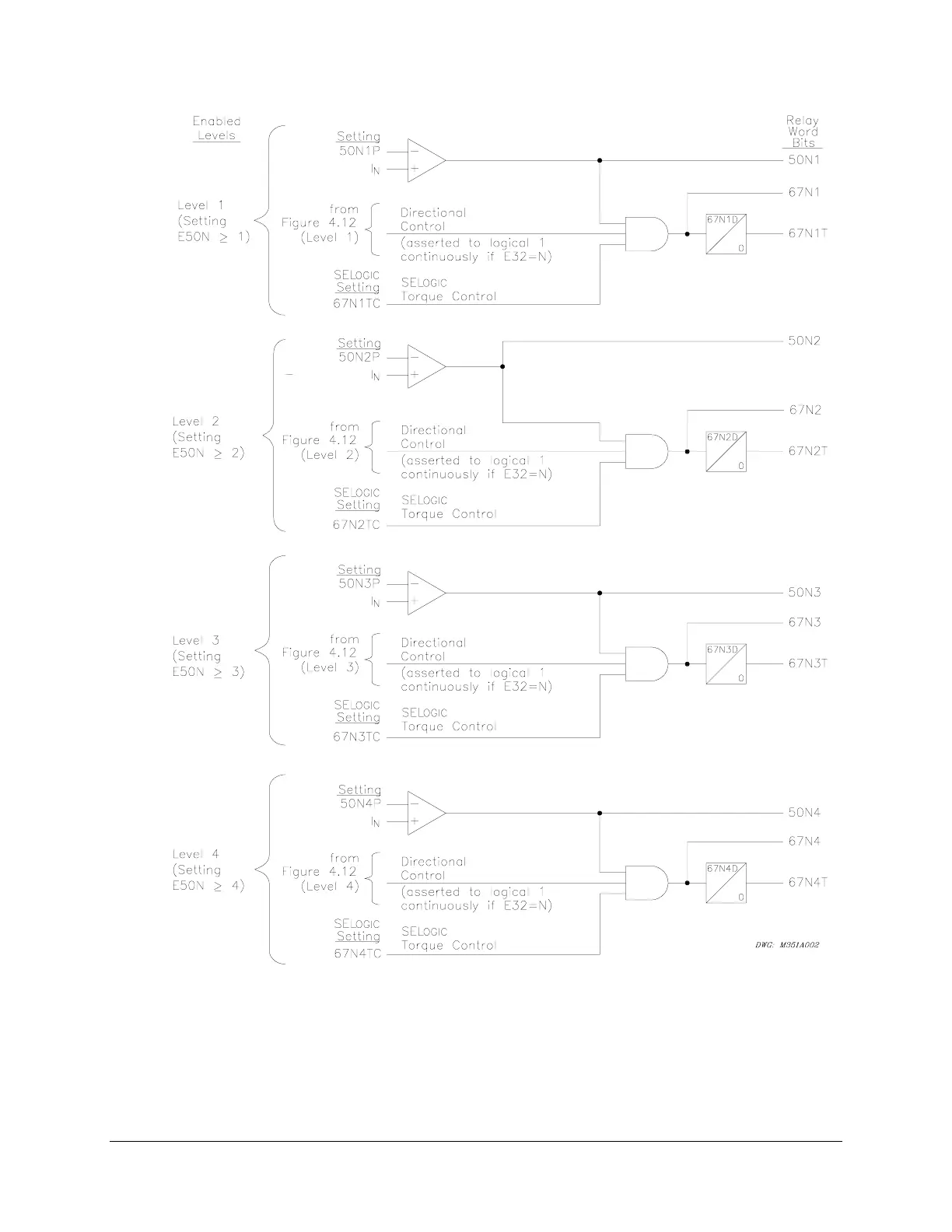

)LJXUH/HYHOV7KURXJK1HXWUDO*URXQG,QVWDQWDQHRXV'HILQLWH7LPH2YHUFXUUHQW

(OHPHQWV:LWK'LUHFWLRQDO&RQWURO2SWLRQ

Loading...

Loading...