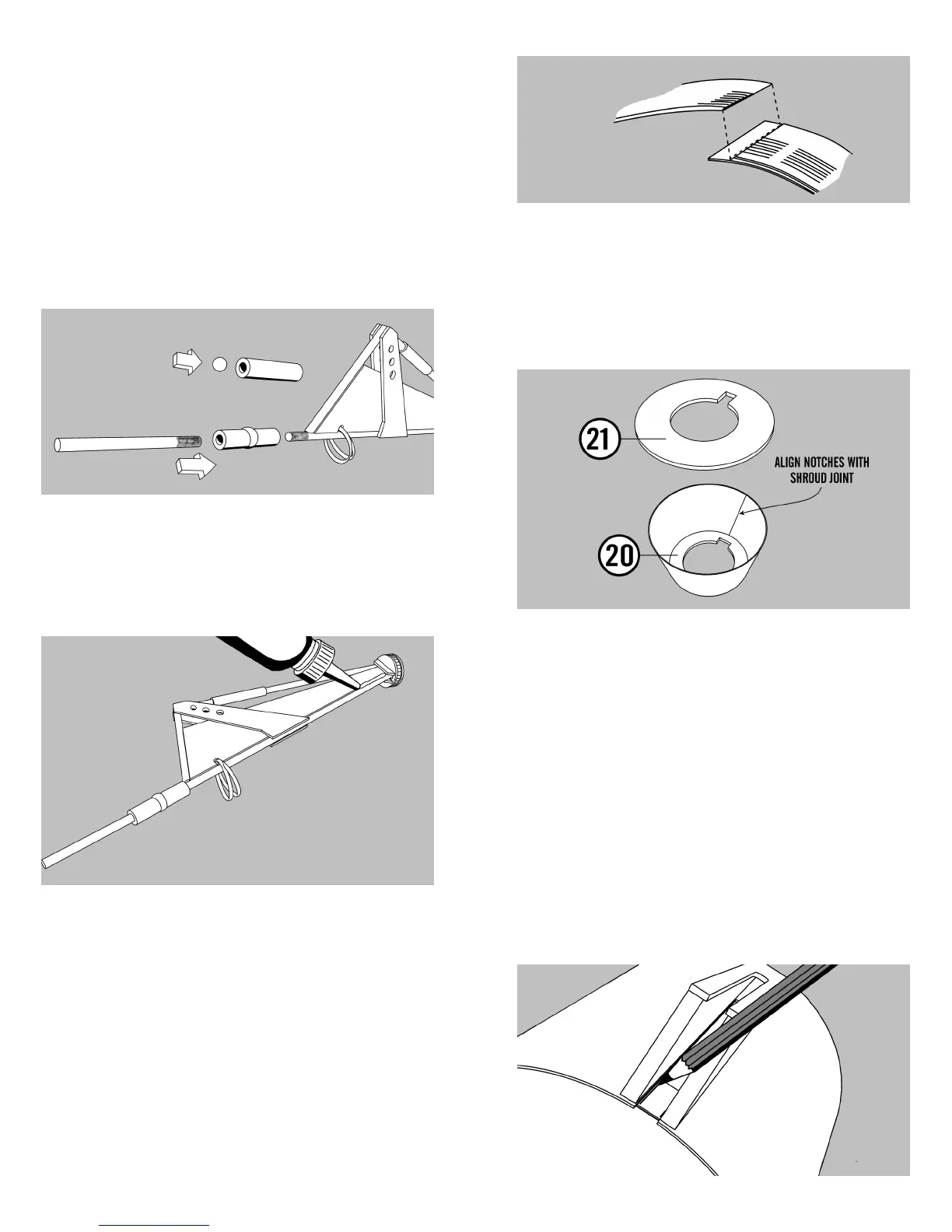

17. While the glue is drying, insert one plastic

bearing in each of the rubber hinges. Use your fin-

gers to slowly work the bearing to the center of

each rubber hinge tube. When all the glue is dry,

slide one of the flexible hinge tubes onto the strut

brace. Push it until the bearing seats against the

dowel. If the bearing does not touch the dowel, trim

a small amount off the end of the hinge tubing, re-

center the bearing and try again. Then insert the

hinge support into the other end of the tube until it

touches the bearing from the other side. Repeat

with the other 3 landing gears.

19. Now that the landing gears are assem-

bled and the glue is dry you may apply sanding

sealer to them. Apply sparingly to keep the weight

down. We recommend using Elmer's Fill and Finish

for sealing. You may apply it to all surfaces except

for the hinge and the hinge support. They must

remain unfilled and unpainted. After you apply the

sealer and sand the landing gears smooth you can

paint them. Paint the gear International Orange or

red. Paint the control cylinders and landing pads

silver.

18. After the glue has dried on the 4 landing

gears, make a glue fillet on all the strut brace joints

as shown it the illustration. Wipe it with your finger

making a fillet and allow the glue to set. Do the

same to both sides of the landing gear on the re-

maining three landing gears.

BREAK TIME!!

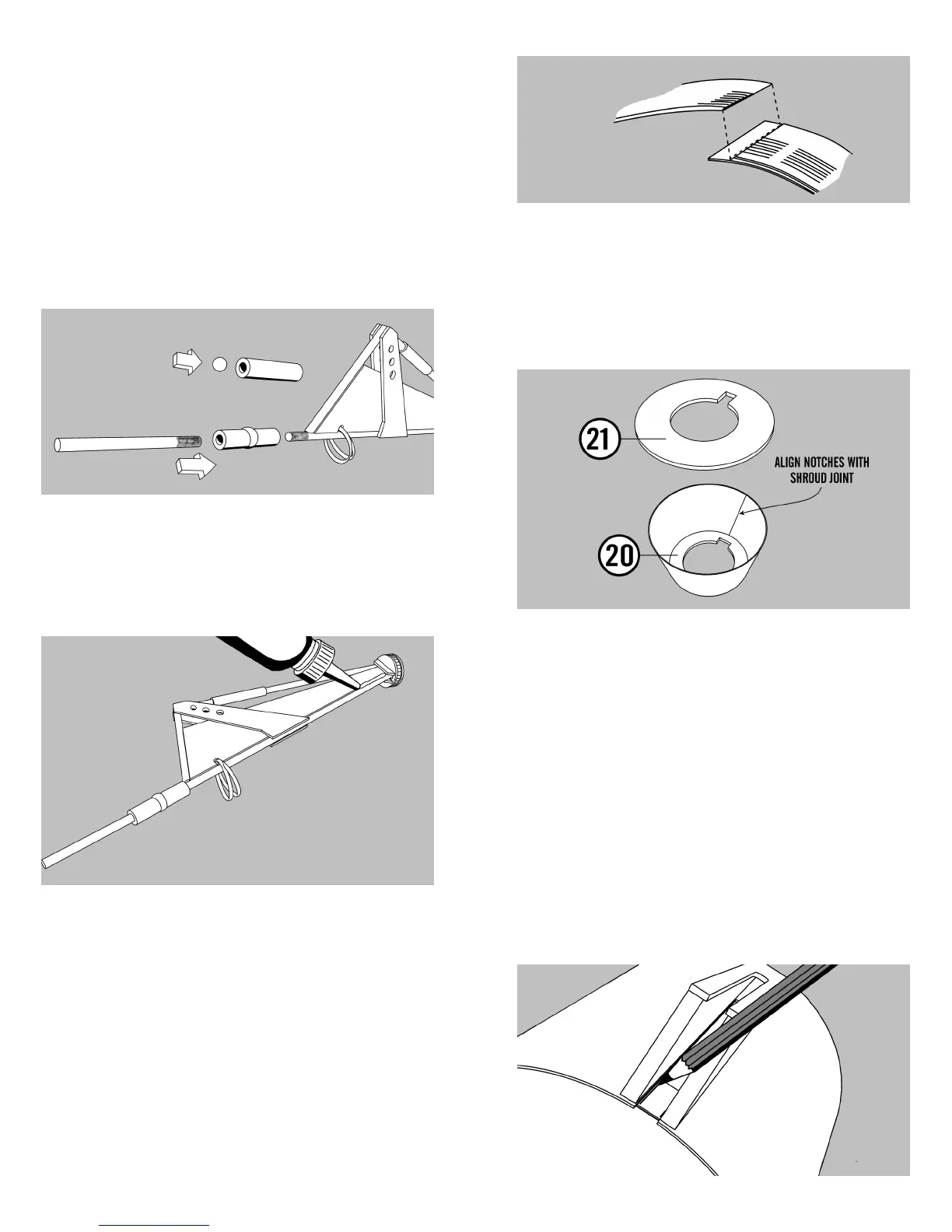

44. Set the small end of the engine shroud

down on a piece of wax paper. Insert the small noz-

zle spacing ring (20) and slide it down until it is

flush with the bottom of the shroud. Make sure the

engine hook notch is centered on the shroud joint.

Run a bead of glue around the ring shroud joint and

allow to dry.

45. Run a bead of glue around the inside of

the large opening in the shroud. Place the large

nozzle spacing ring (21) in the shroud and glue it

into place. Make sure that the engine hook notches

are in line with each other.

46. Next trim off the last 1/4” of each landing

gear opening in the descent body tube. Then slide

the entire landing gear assembly into the rear of the

descent stage. The aft bulkhead should be 1/16”

inward from the rear of the body tube. Align so

that the landing gears can move freely. Without

moving the bulkhead mark each exposed section of

the internal ring. The marks should be at the inside

edge of each gear housing. The landing gear are

not shown in the illustration below.

Loading...

Loading...