35. Glue the shroud together by applying

glue to the shroud tab and align the two sides to-

gether. Hold in place until it sets up and then leave

to dry. White glue works best for shrouds since it

does not shrink as much as some glues.

36. Follow the same procedure that you just

did in step 35 to the command module shroud. Af-

ter the glue has set for several minutes then press

the Command module bulkhead into the larger

opening and glue into place. Make sure the bulk-

head is even with the end of the shroud. Sanding

may be necessary to get the proper fit.

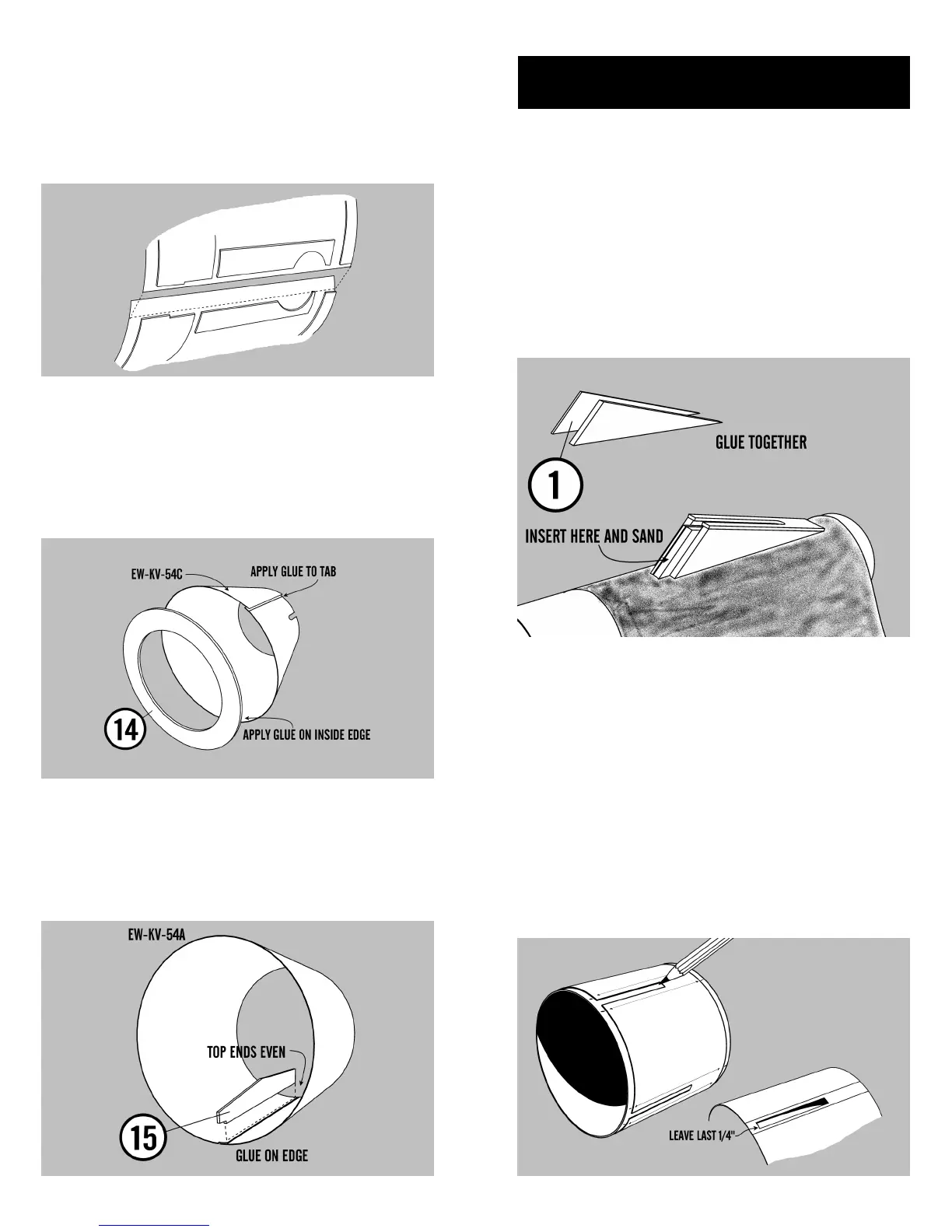

37. Punch out the notched ascent module

brace (15). Apply glue to the longest straight edge

and glue the brace to the shroud joint so that the

notched end is toward the large end of the shroud.

Hold in place until it sets and make sure it points

straight away from the shroud.

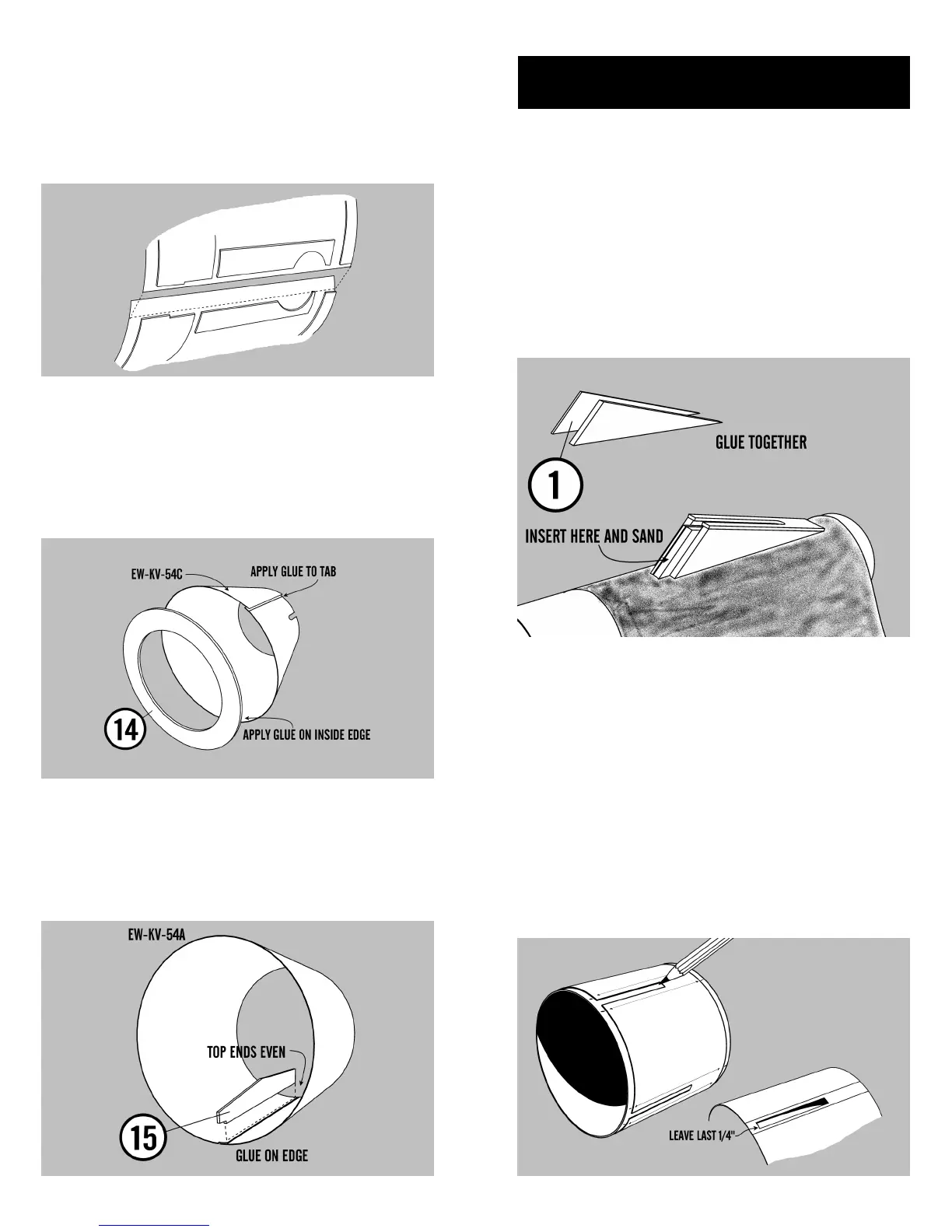

24. Punch out the balsa and paper (1) gear

housing spacers. Glue the two together and let dry.

Insert the spacer in between the groove in the gear

housing. Wrap a piece of sandpaper around the

chute tube (BT-60FG) and round the edges of the

gear housing by sanding them back and forth

against the tube. Do the same to the other three

housings. Make sure that the bottom edges of the

gear housings fit smoothly against the descent

stage tube (BT-100CE.) The spacer will be discarded

when you are finished with it.

MAIN ASSEMBLY

25. Cut out the descent stage marking guide.

Wrap the guide around the descent stage tube (BT-

100CE) and tape with masking tape. Center it over

the tube and mark the tube at each of the arrow

points. Draw a line on the tube around each of the

landing gear openings with a straight edge. Very

carefully cut out the landing gear openings in the

body tube except for the last 1/4” of the tube. The

tube will become very flexible and hard to work

with. Patience is required to avoid cutting through

the large tube. (Refer to illustration)

Loading...

Loading...