13

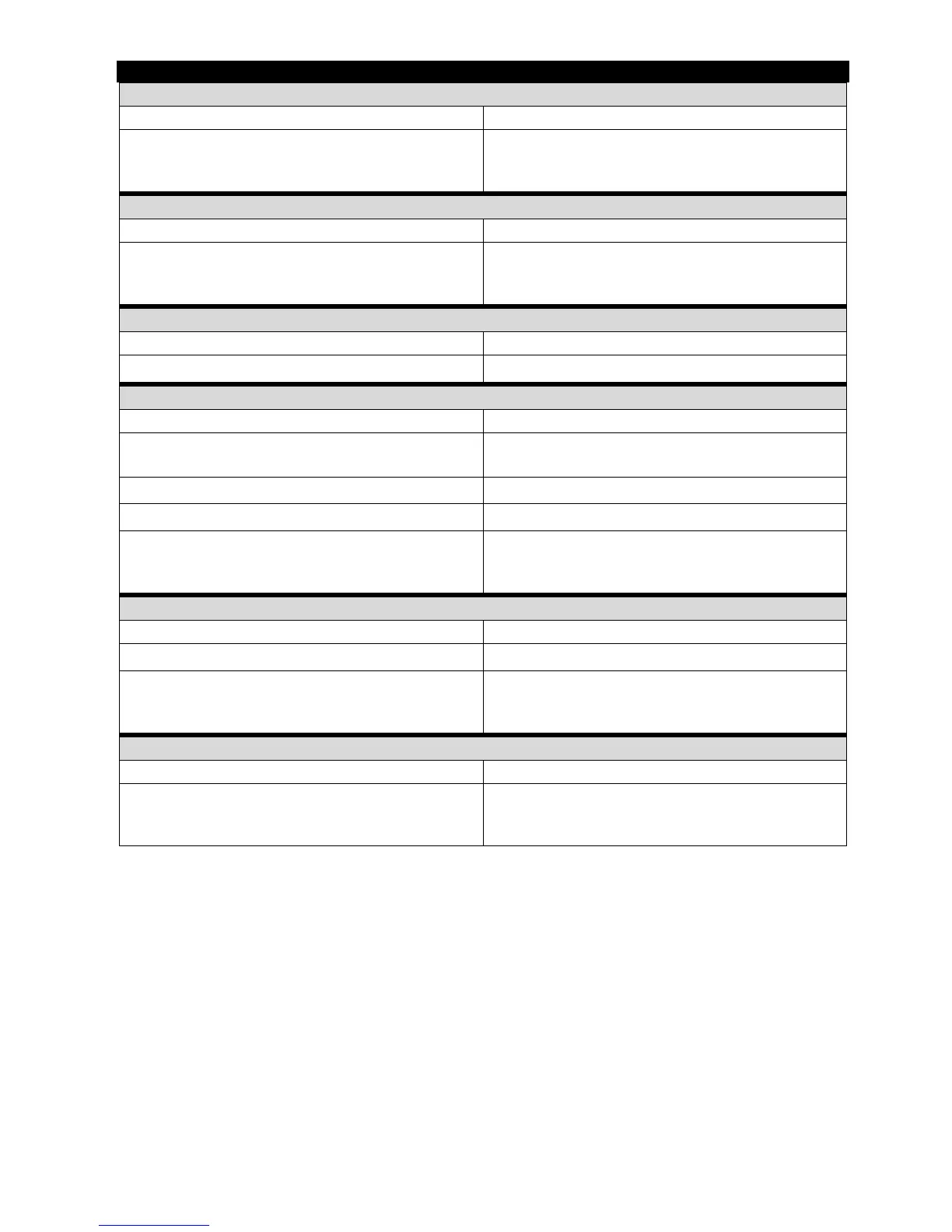

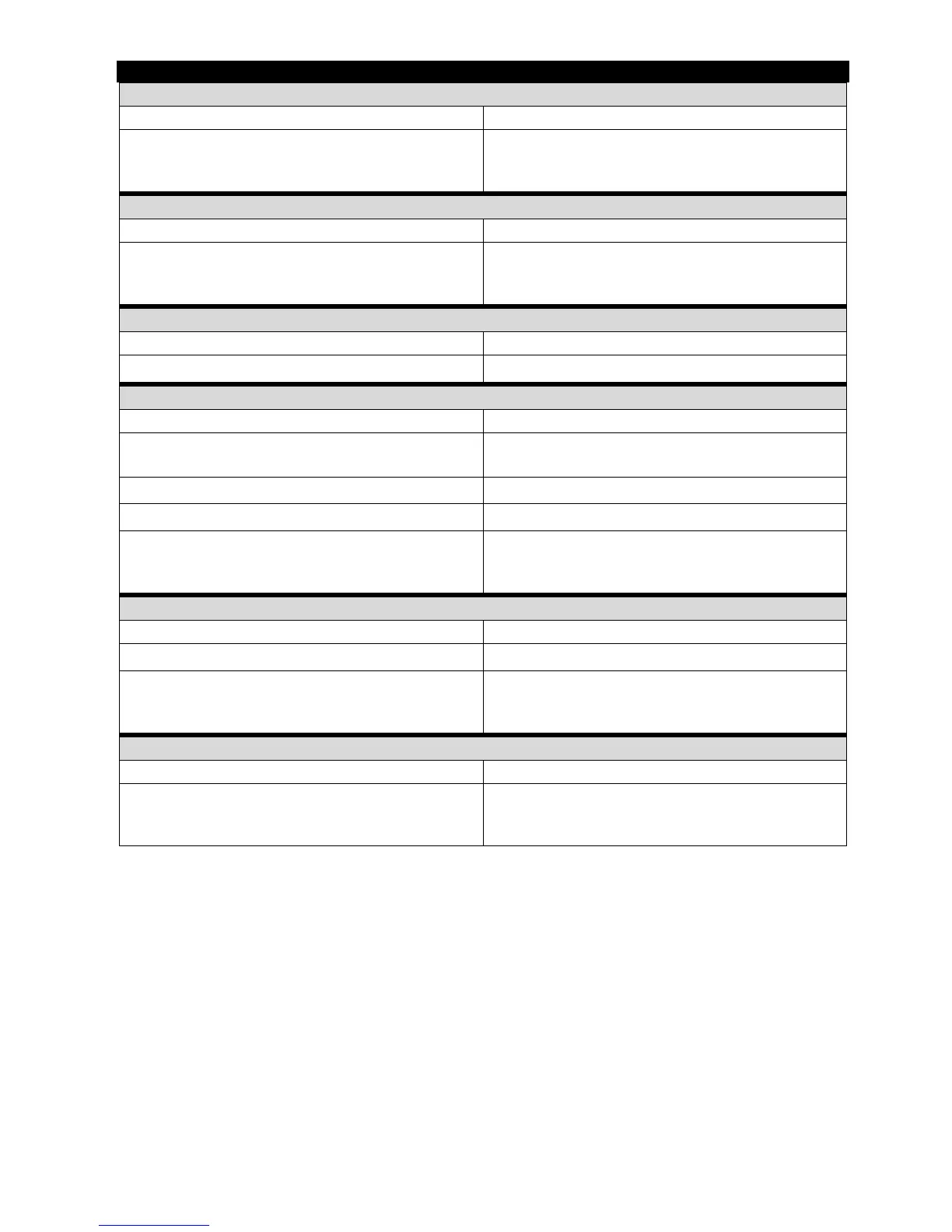

Troubleshooting

Symptom 6. Air leaks at fittings.

Probable Cause Remedy

Fittings are not tight enough. Tighten fittings where air can be heard escaping.

Check fittings with soapy water solution.

Do not overtighten.

Symptom 7. Air leak in air tank.

Probable Cause Remedy

Defective or rusted air tank. Air tank must be replaced.

Do not attempt to repair air tank!

Do not weld, repair or make modifications.

Symptom 8. Air blowing from inlet filter.

Probable Cause Remedy

Damaged inlet (reed) valve. Contact SENCO Customer Service.

Symptom 9. Insufficient pressure at air tool or accessory.

Probable Cause Remedy

Pressure regulator knob not turned to high

enough pressure or defective pressure regulator.

Adjust pressure regulator knob to proper setting

or replace.

Restricted air intake filter. Clean.

Air leaks. Check for leaks and repair.

Air compressor is not large enough for air

requirement.

Check the accessory air requirement. If it is

higher than the CFM or pressure supply of the air

compressor, you need a larger air compressor.

Symptom 10. Air compressor not making enough air.

Probable Cause Remedy

Restricted air intake filter. Clean.

Defective (reed) valve. Drain air tank and measure pump up time.

Compare to specifications. If lower, remove pump

head and inspect valve plate, clean or replace.

Symptom 11. Moisture in discharge air.

Probable Cause Remedy

Condensation in air tank caused by high level of

atmospheric humidity or air compressor is not run

long enough.

Drain air tank after every use. Drain air tank more

often in humid weather and use an air line filter.

Loading...

Loading...