9

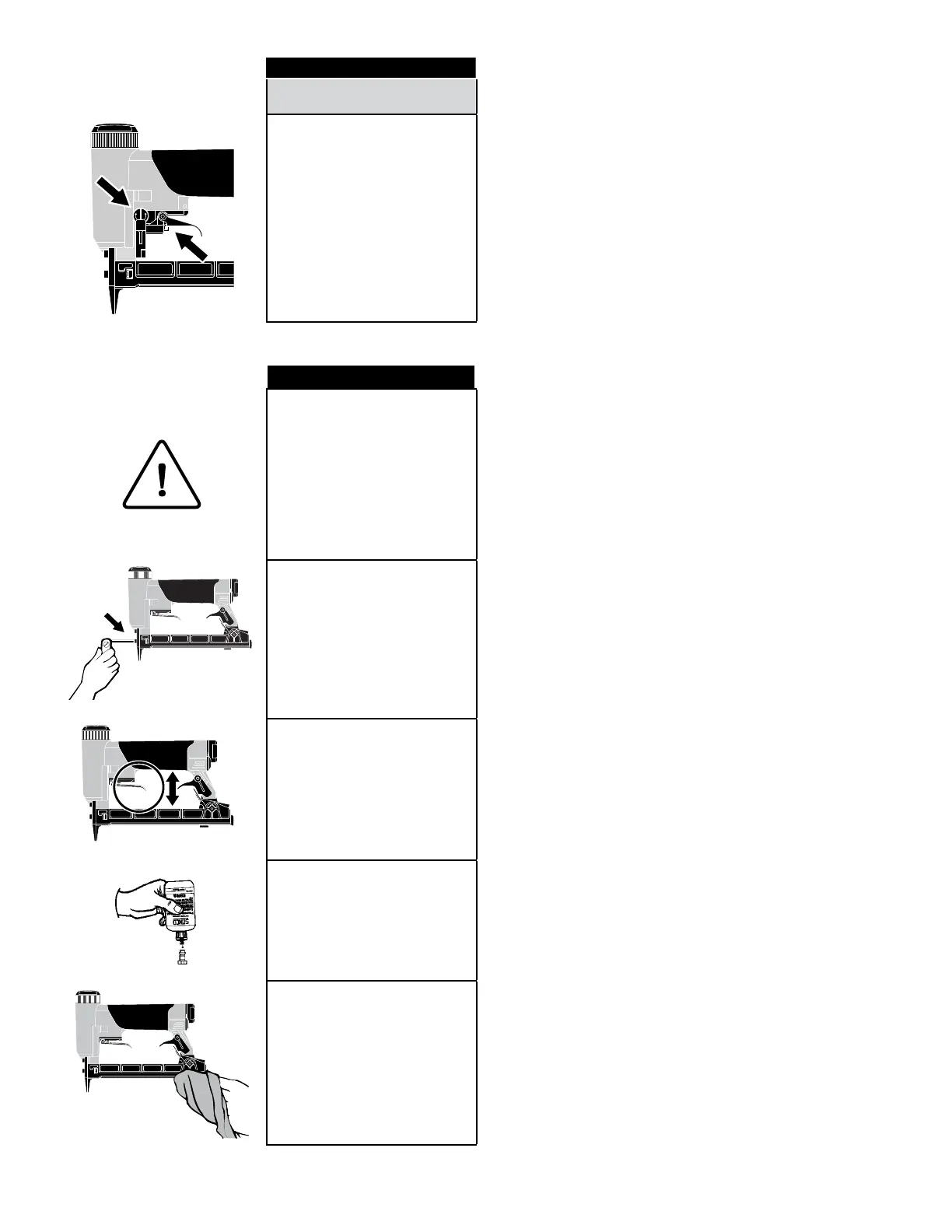

This tool is equipped with a drive

rate adjustment to adjust the

speed.

Rotate the screw, not more than

three turns, counter-clockwise

(

Q) to increase the drive rate.

Rotate the screw clockwise (

P),

not more than three turns, to

slow the drive rate.

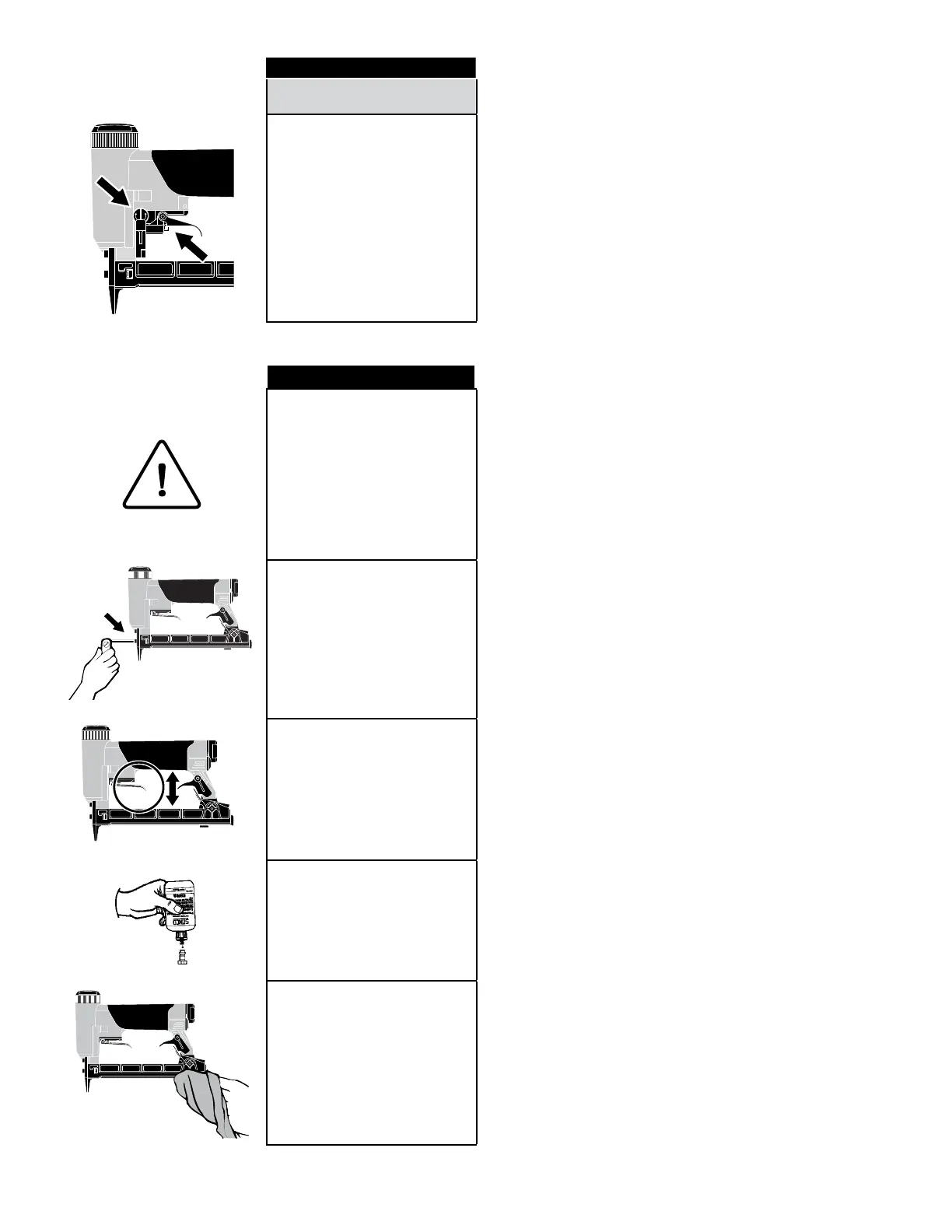

For single shot operation, pull

trigger only partially. For auto-

matic operation, pull trigger fully.

Repairs other than those

described here should be per-

formed only by trained,

qualified personnel.

Read section titled “Safety

Warnings” before maintaining

tool.

All screws should be kept tight.

Loose screws result in unsafe

operation and parts breakage.

With tool disconnected, make

daily inspection to assure free

movement of trigger. Do not use

tool if trigger sticks or binds.

Squirt Senco pneumatic oil (5 to

10 drops) into the air inlet daily

(depending on frequency of tool

use). Other oils may damage

O-rings and other tool parts.

Wipe tool clean daily and

inspect for wear. Use non-flam-

mable cleaning solutions only if

necessary.

DO NOT SOAK.

Caution: Such solutions may

damage O–rings and other tool

parts.

Loading...

Loading...