Introduction

1. The control valve, fittings and/or bypass are

designed to accommodate minor plumbing mis-

alignments but are not designed to support the

weight of a system or the plumbing.

2. Do not use Vaseline, oils, other hydrocarbon lubri-

cants or spray silicone anywhere. A silicon lubri-

cant may be used on black o-rings but is not nec-

essary. Avoid any type of lubricants, includ-

ing silicone, on red or clear lip seals.

3. The nuts and caps are designed to be unscrewed

or tightened by hand or with the special plastic

wrench. If necessary pliers can be used to

unscrew the nut or cap. Do not use a pipe wrench

to tighten or loosen nuts or caps. Do not place

screwdriver in slots on caps and/or tap with a

hammer.

4. Do not use pipe dope or other sealants on threads.

Teflon tape must be used on the threads of the 1”

NPT elbow or the 1/4” NPT connection and on the

threads for the drain line connection. Teflon tape

is not necessary on the nut connection or caps

because of o-ring seals.

5. After completing any valve maintenance involving

the drive assembly or the drive cap assembly and

pistons, press and hold NEXT and REGEN but-

tons for 3 seconds or unplug power source jack

from the printed circuit board (black wire) and

plug back in. This resets the electronics and

establishes the service piston position. The dis-

play should flash all wording, then flash the soft-

ware version (e.g. 154) and then reset the valve to

the service position.

6. All plumbing should be done in accordance with

local plumbing codes. The pipe size for the drain

line should be a minimum of 1/2”. Backwash flow

rates in excess of 7 gpm or length in excess of 20’

require 3/4” drain line.

7. Solder joints near the drain must be done prior to

connecting the drain line flow control fitting.

Leave at least 6” between the drain line control

fitting and solder joints when soldering pipes that

are connected on the drain line control fitting.

Failure to do this could cause interior damage to

the drain line flow control fitting.

8. When assembling the installation fitting package

(inlet and outlet), connect the fitting to the

plumbing system first and then attach the nut,

split ring and o-ring. Heat from soldering or sol-

vent cements may damage the nut, split ring or o-

ring. Solder joints should be cool and solvent

cements should be set before installing the nut,

split ring and o-ring. Avoid getting primer and

solvent cement on any part of the o-rings, split

rings, bypass valve or control valve.

9. Plug into an electrical outlet. Note: All electrical

connections must be connected according to local

codes. (Be certain the outlet is uninterrupted.)

10. Install grounding strap on metal pipes.

Page 4

General Warnings

Table 1

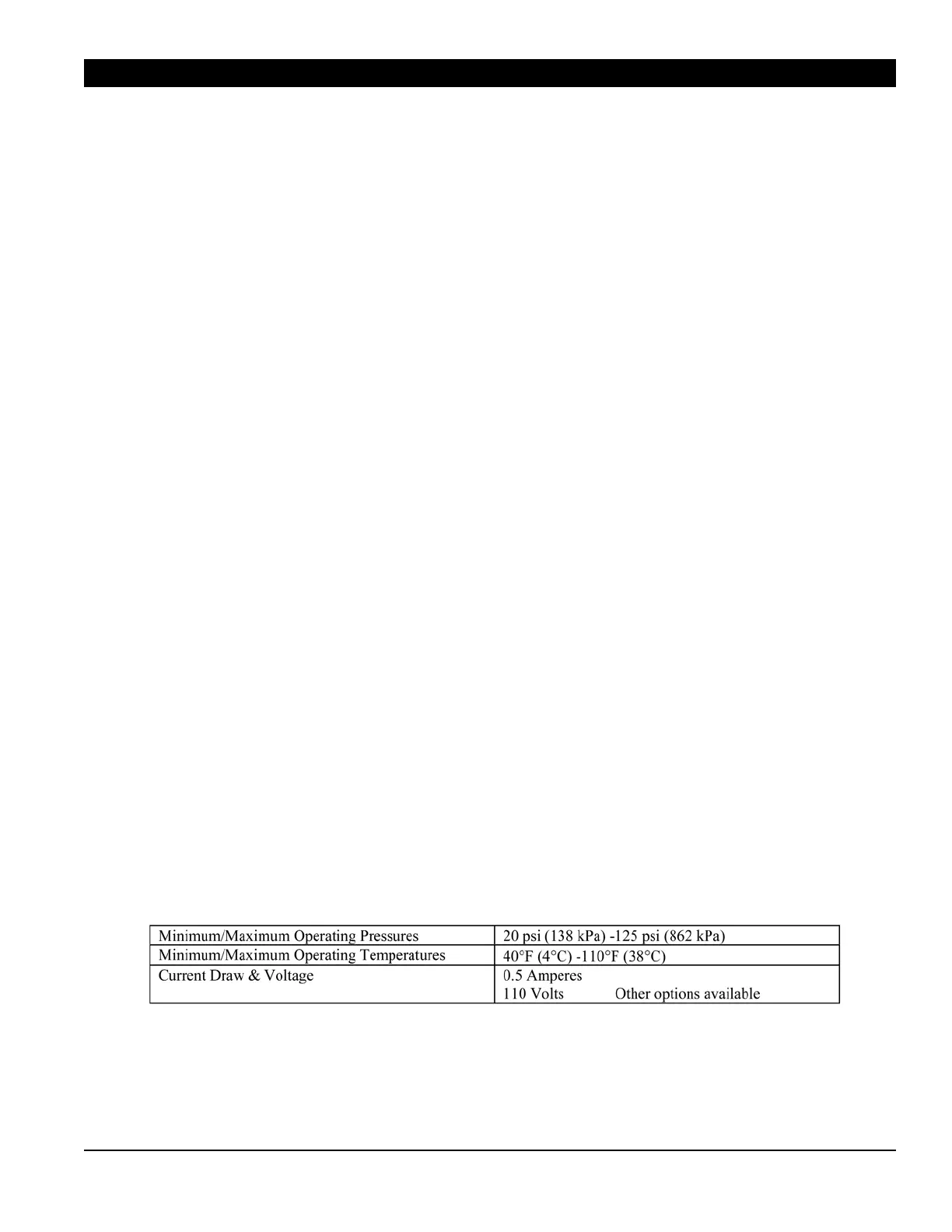

System Specifications

Loading...

Loading...