36 Sentry Equipment Corp

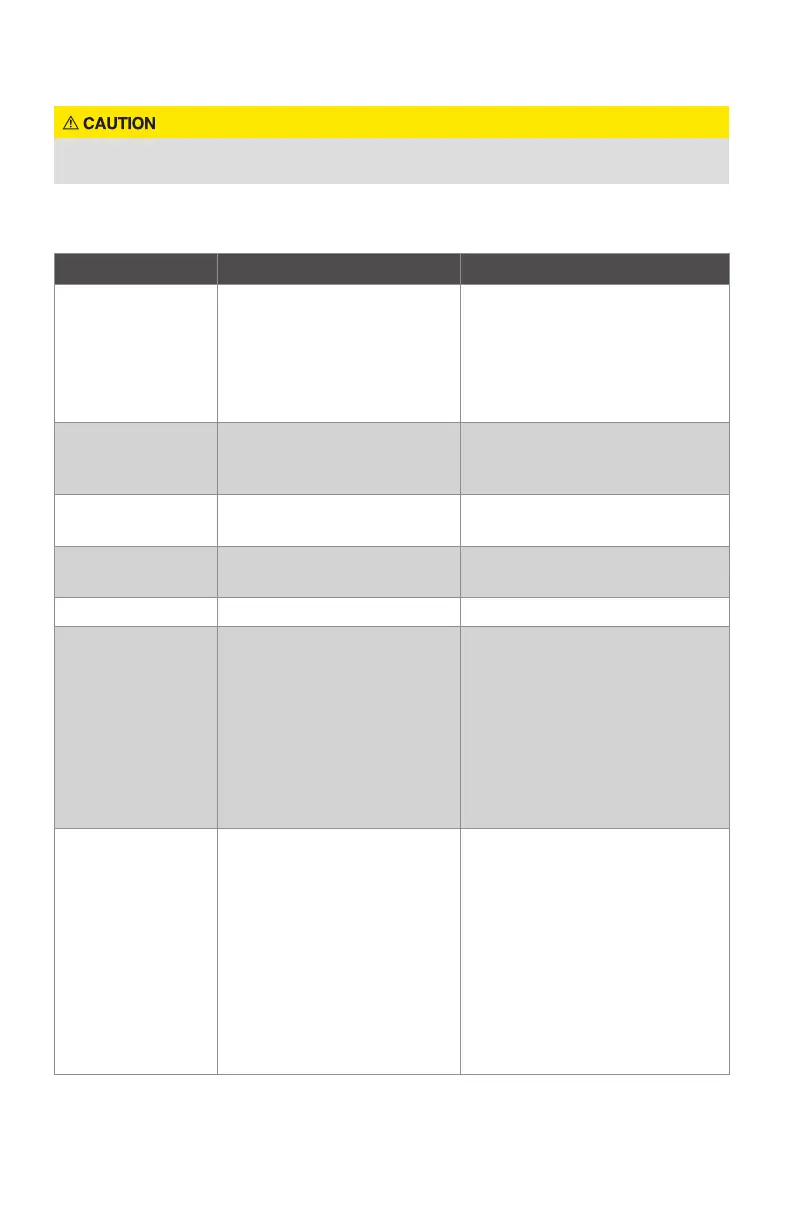

Troubleshooting Guide

Applying excessive torque on the PRV Shaft or PRV coupling will result in damage to the unit.

Follow the appropriate procedure when dislodging PRV.

Table 5. Troubleshooting Guide

Symptom Possible Problem(s) Remedy

Elevated Sample

Temperature

Loss of cooling water ow

Increase in cooling water

inlet temperature

Scaled cooler

Increased sample ow

Check cooling water supply

Reduce cooling water

temperature or increase ow

Chemically clean (see cooler

maintenance)

Adjust sample ow rate

Reduced Sample

Flow

Plugged line

BPR/RV failure

Blowdown line and exercise

ow control valve

See leaking BPR/RV

Leaking Valve

Stems

Loose or worn packing Tighten packing nut or replace

packing

Leaking Cooler Loose housing from thermal

shock or worn gasket

Tighten bolts on head assembly

or replace gasket if cut or worn

Leaking BPR/RV Diaphragm failure Replace diaphragm

Motor Alarm Locked PRV

Faulty motor encoder or

motor

Faulty output board inside

Sample Sentry II controller

Faulty power or signal

wiring between Sample

Sentry II controller and

motor

In most cases, you may need to

remove the PRV and manually

clean it. If Alarms continue

please contact the factory for

truobleshooting support.

PRV shaft will not

turn

Debris in PRV

PRV Position Incorrect

If possible, attempt to dislodge

debris by using your hand to

torque the PRV coupling. If this

fails, close sample isolation valve,

remove power from Sample

Sentry II, remove PRV and clean

debris from PRV. Replace PRV,

supply power to Sample Sentry

II, wait for unit to nish its startup

routine, and open sample

isolation valve.

Loading...

Loading...