Engine should be stored in place of dry, clean and good ventilation.

Chemical medicine is strictly prohibited nearby.

The above preservation method could store the engine for 3 months, if the preservation is overdue,

the engine should be preserved as above again.

CHAPTER IV THE STRUCTURE OF ENGINE

1 . CYL I NDE R B LO C K AS SE MB LY .

The cylinder block is planer-type with the full supporting bearing and dry cylinder liner,

which the shoulder is 0.02 - 0.10mm higher than the cylinder block upper surface. The height

difference of adjacent liner is not more than 0.03mm.

Dismounting cylinder liners must use the special tools and should keep the cylinder bore inner

surface and the cylinder liner outer surface dry and clean, coating grease is prohibited.

The water cavity of cylinder block is tested by 400kpa water pressure for 2 minutes. The oil

channel should be tested by 600kpa oil pressure for 1 minute, and leakage is not allowed.

Cylinder block have valve tappet cavity opener, a connecting pipe on the cover plate connects

with breather. The oil filter and water drain cock is assembled on the cylinder block by the side of

injection pump.

2 . C YL I NDE R H E AD A SS E MBL Y

Cylinder head is a unitary one, and is made of HT200 cast iron plus to cuprum chromium or

HT250 cast iron.

Cylinder head water cavity is tested by 400kpa water pressure for 3 minutes. No leakage is

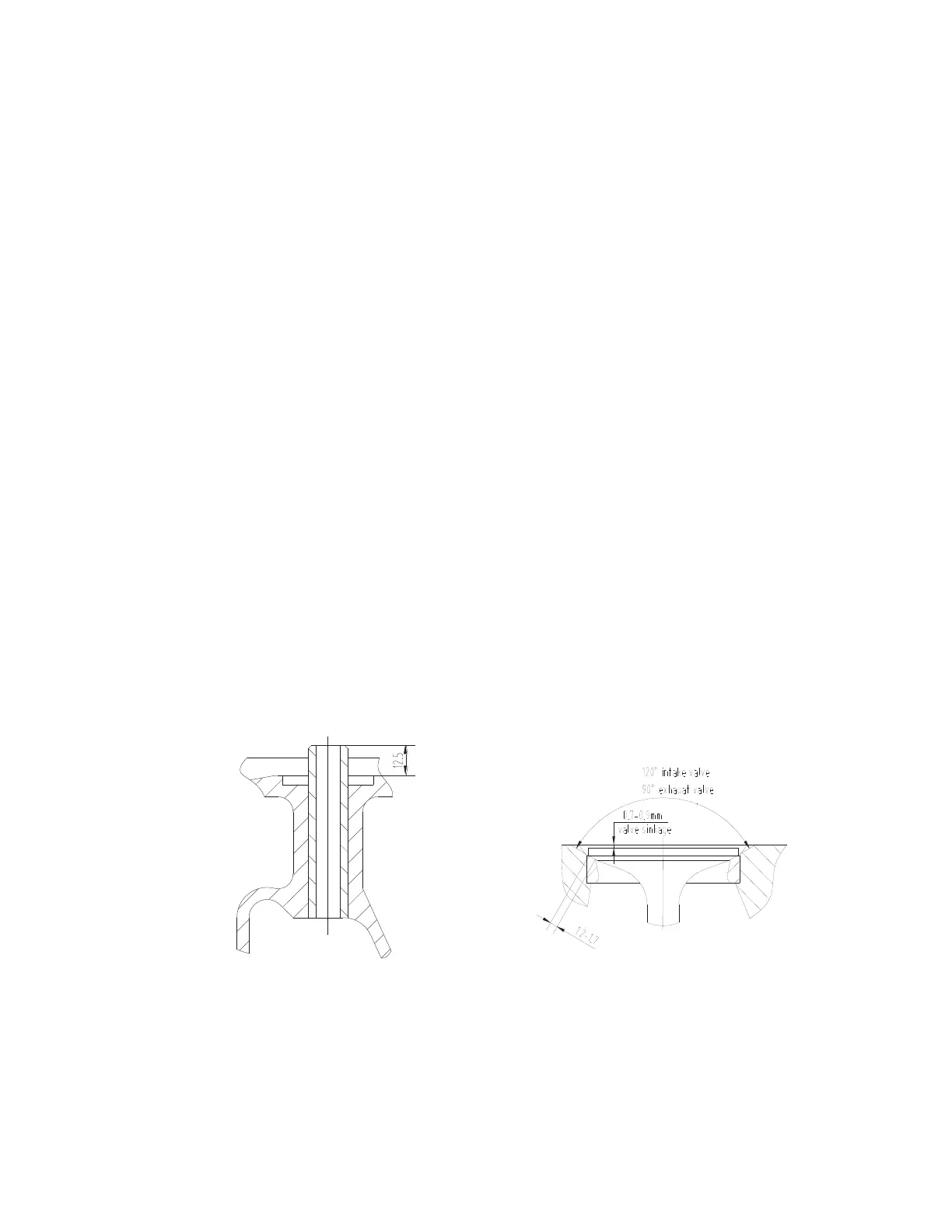

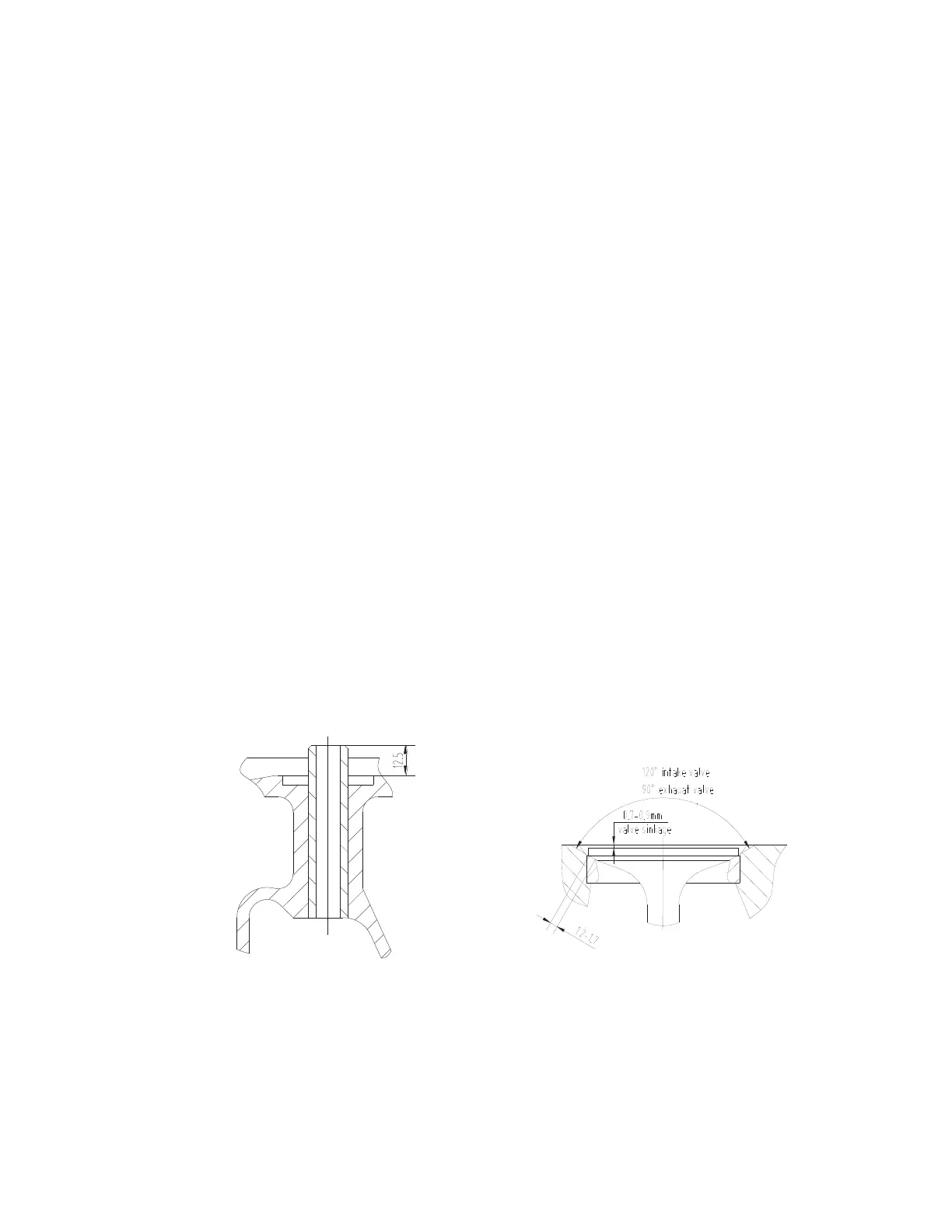

allowed. Valve guide is pressed into cylinder head leaving a protruding of 10mm,shown as Fig.2.

The cone angles of intake and exhaust valve are respectively 90°and120ć. The width of

contacting surface is 1.2--1.7mm. The sinkage of intake and exhaust valve is 0.7-0.9 mm shown as

Fig.2.3.

ig.2 Valve guide mounting dimension Fig.3 Valve sinkage diagram

There is an oil hole on the cylinder head cover, which is designed for filling in oil. While

mounting cylinder head gasket, pay attention to the position of oil hole, water hole and screw hole.

Incorrectly mounting is not allowed. Before mounting cylinder head, pour 20g lubrication into

each cylinder liner surface.

Cylinder head is positioned on block by positioning bushing and tightened by cylinder head

bolts. Tightening torque is 135~150N.m which should be effected twice.

Loading...

Loading...