3. Insufficient fuel supply.

1) Delivery pipe & fuel filter blocked.

2) Replace nozzle tip or injector.

5. Incorrect fuel supply advance angle.

6. Too much carbon deposit in chamber.

6. Disassemble cylinder head and remove carbon

deposit.

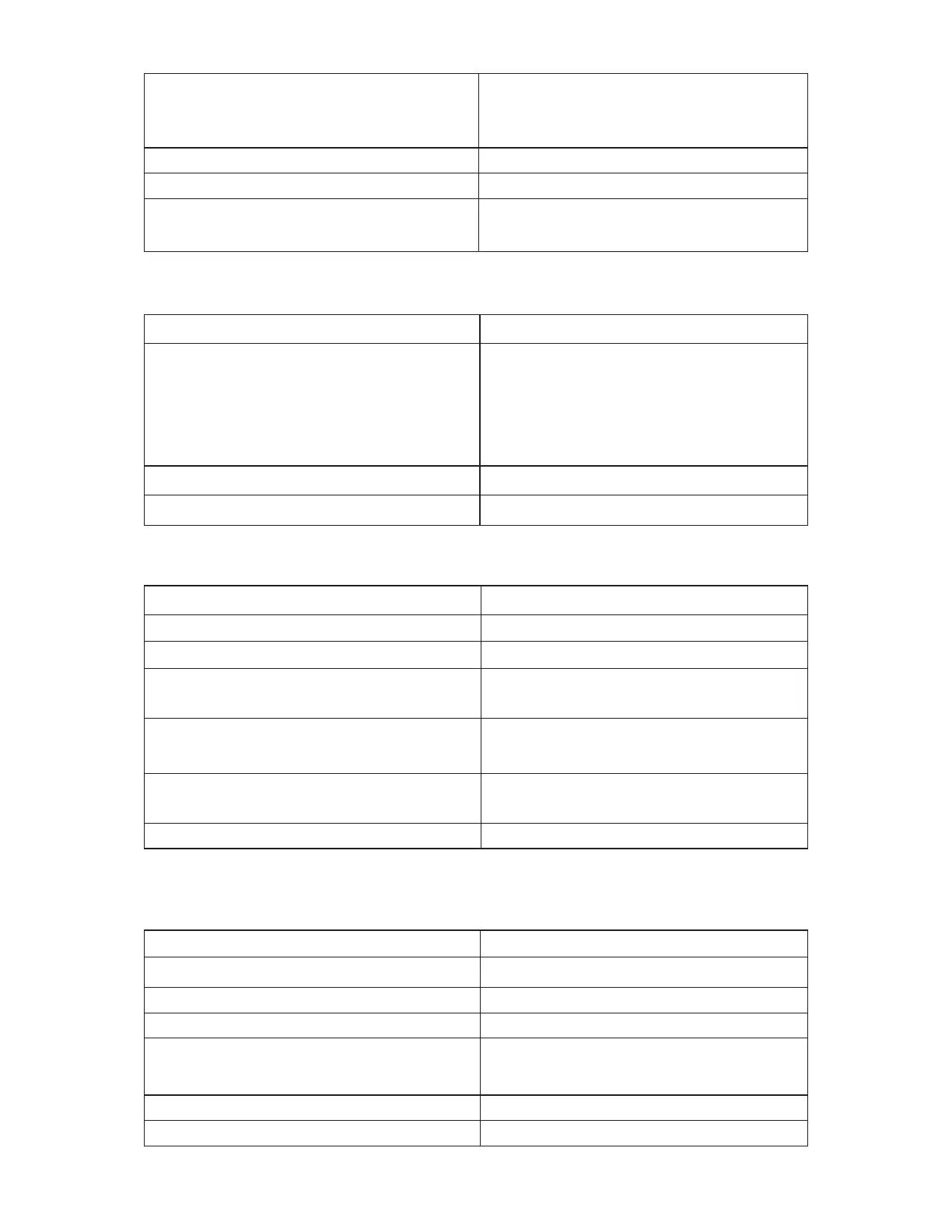

C: ENGINE STOP SUDDENLY

Trouble Cause Remedy

3. Replace filter cartridge.

D: ENGINE RUNNING WITH KNOCKING SOUND.

Trouble Cause

1. Fuel supply too early or too late.

1. Readjust fuel supply advance angle.

2. Valve clearance to big

2. Readjust valve clearance.

3. Too big clearance between piston and cylinder liner.

cylinder liner when necessary.

4. Too big clearance between piston pin and connecting

rod bushing, having beating sound.

4. Check and replace connecting rod bushing when

necessary.

5. Too big clearance of main bearing or connecting rod

bearing, having ramming sound.

5. Check and replace connecting rod bearing or main

bearing when necessary

6. Valve knock with piston top.

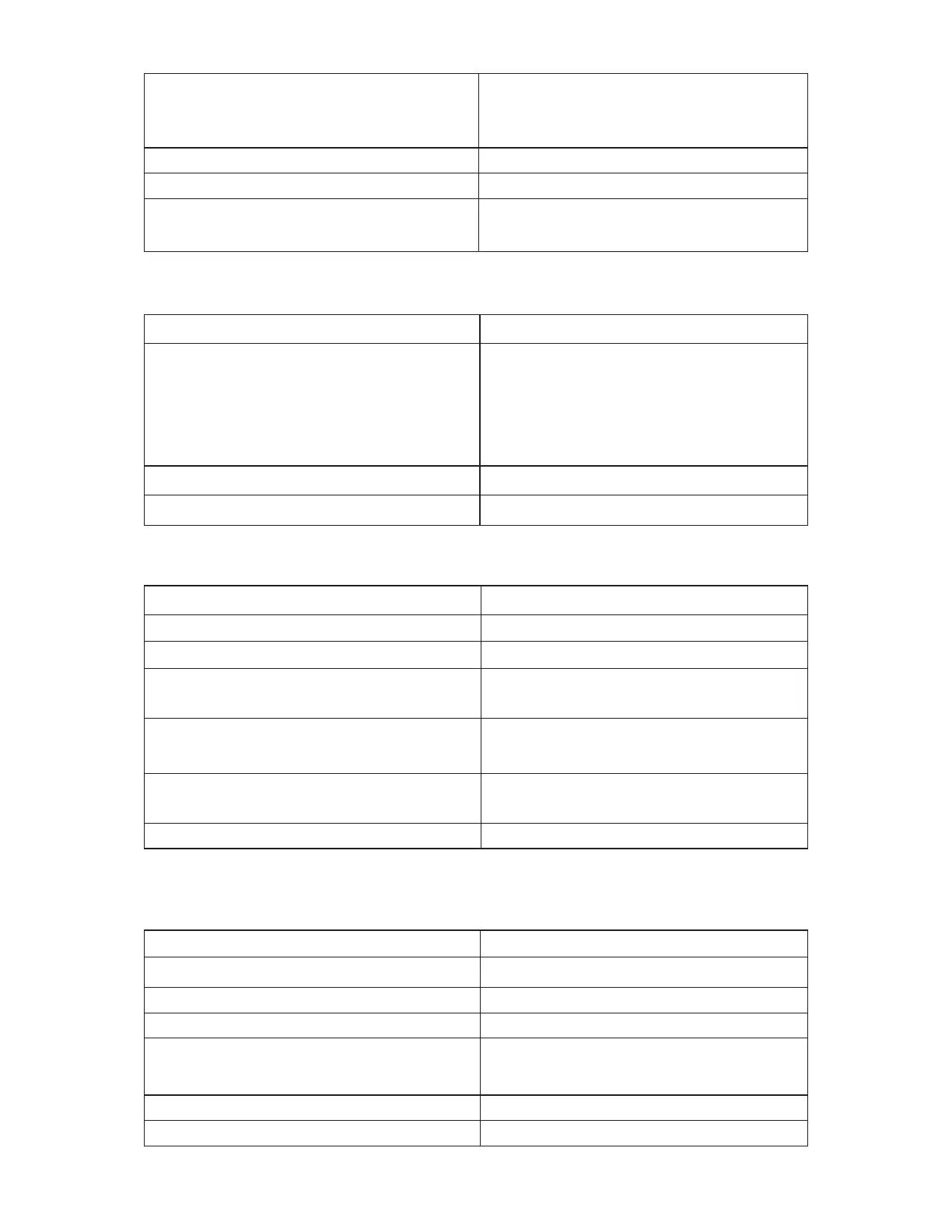

E: OIL PRESSURE TOO LOW.

1.Insufficient oil in sump.

2. Oil pipes or oil filter cartridge blocked.

2. Clean and replace when necessary.

3. Oil viscosity too low.

3. Replace oil according to technical requirement.

4. Cylinder head gasket, water pump packing or gear

case cover packing damaged to induce water into oil.

4. Replace damaged gasket ,packing and oil

5. Suction fuel pipe connector leakage

6. Oil pump rotors seriously worn out.

6. Replace rotors and adjust clearance.

Loading...

Loading...