CR AN KS HA FT A ND F LY WH EE L AS SE MB LY

Crankshaft is made of QT900-2 nodular cast iron. Main bearing is made of steel back 20%

alloy with high tin and aluminum which can't adhere oil while mounting to avoid affecting its

radiating efficiency and damaging bearings. The thrust plate is of the same material as main

bearing. They are mounting on two sides of the last main bearing and positioned by the convex tail

of the lower thrust plate. When mounting, the oil channel of thrust plate should face to crankshaft

thrust surface. Reverse mounting is not allowed.

Main bearing cover is machined in couple with cylinder block. Cylinder block No. and

sequence No. are engraved on main bearing cover. The forth-main bearing cover is positioned by

positioning bushing. When mounting, the top arrow on main bearing should back- face to the side

of camshaft and compile the number from front end.

Reverse mounting is not allowed. Tightening torque of main bearing bolts is 115~130N.m. when

tightening, firstly tighten the central one, then the two sides alternatively. After tightened, the

crankshaft should run freely.

Flywheel is positioned by pin and tightened by bolts on the crankshaft rear end. Bolts are

tightened at a torque of 50 - 60 N. m alternatively on diagonal line. The belt pulley is positioned

by starting paw, tightened at a torque of 160-170 N.m on the crankshaft front end. Pounding or

beating is strictly prohibited when mounting or dismounting.

Crankshaft, flywheel and belt pulley, have been balanced. Care must be taken of ensuring its

balance when replacing parts. Both flywheel housing and gear case cover are mounted with oil

seal. Do not damage them when mounting or dismounting.

4 . P IS TO N AN D CO NN E CTI NG RO D ASS E MB LY

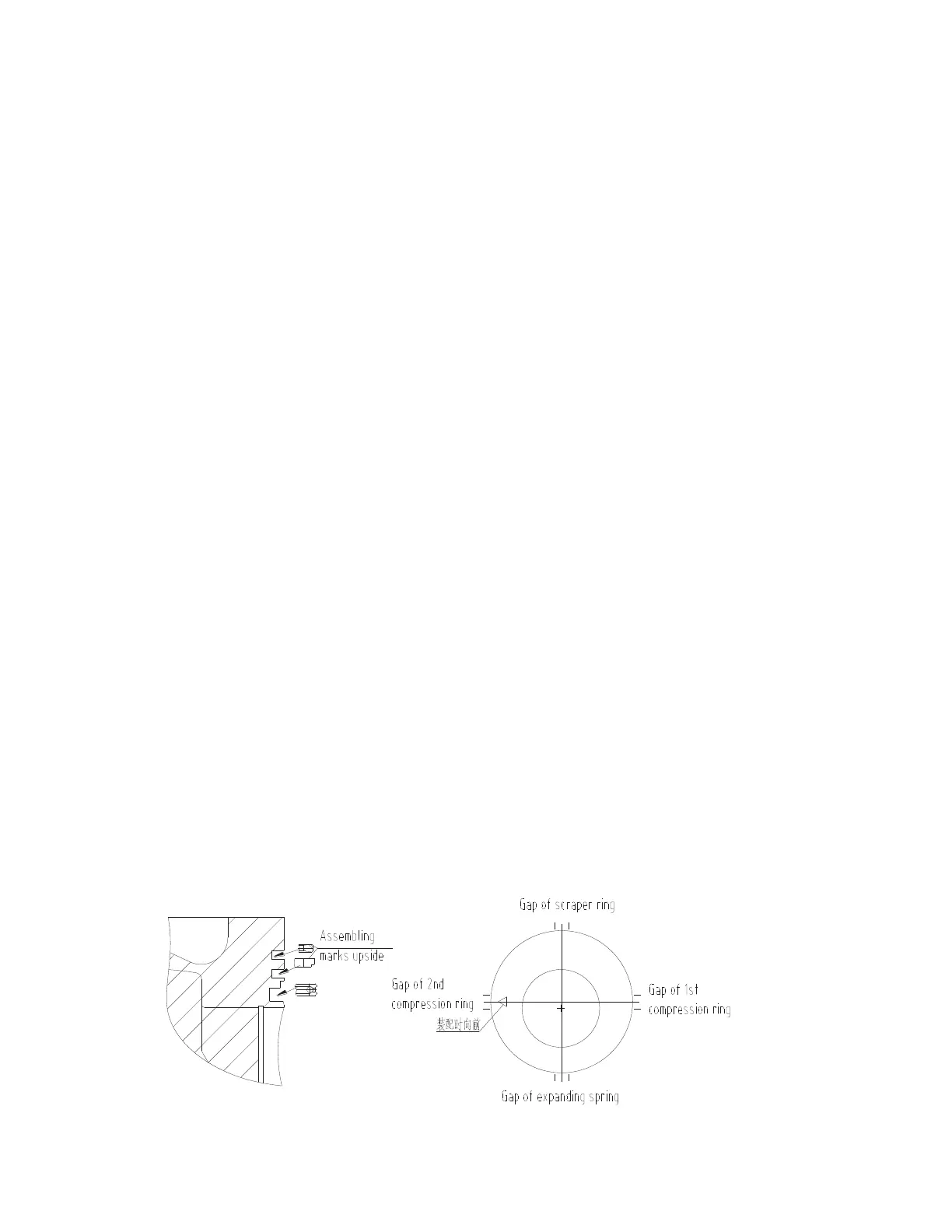

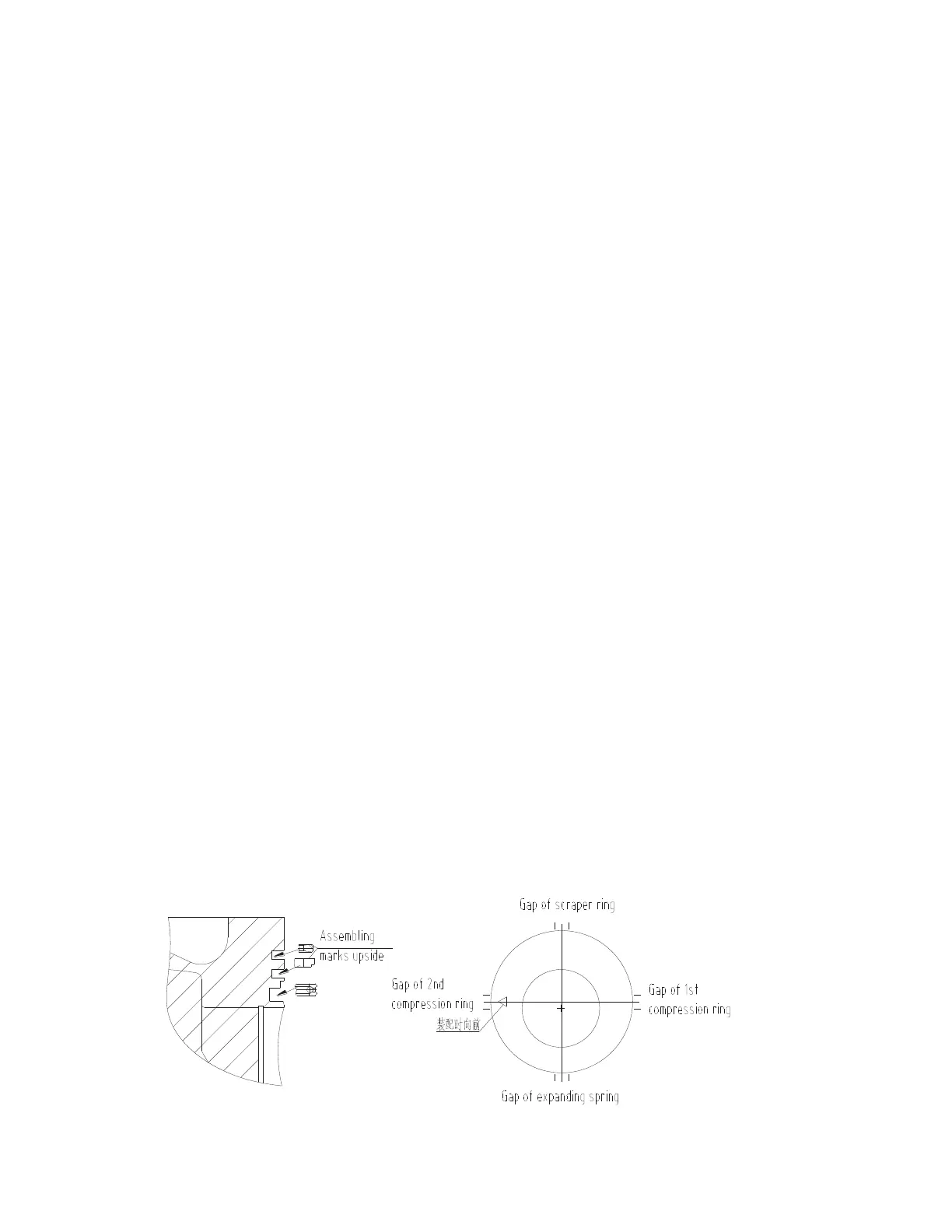

The piston is made of aluminum alloy ZL109, which has tow air--compression rings and one

oil scraper ring.

The first compression ring is of chrome- plated barrel shape; the second one is of taper shapes.

The oil scraper ring is spiral spring expanding ring with the inner cylinder face, inner round face

and outer cylinder edge face plated by chrome, pay attention that the spring connecting point

should space out 180° apart from the oil scraper ring gap.

It is advised to install the piston ring with special expander; excessive expanding is not

allowed to avoid breaking. The ring should turn easily in the slot and can fall into the slot

supporting face by itself. The piston concave should be poured lub.oil.

The piston ring shape and its opening direction, please refer to Fig.4 and Fig.5

Fig.4 Piston ring shape Fig.5 Piston ring opening direction

Loading...

Loading...