10

H-VCO, VIF-VCO & S-TRAP fo ADJUSTMENT

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 H-VCO ADJ

(Manual Adj)

(I2C BUS CONTROL) (1) In No signal (RASTER) condition.

(AUTO & MANUAL ADJ)

(2) Go to service mode, choose service data

V03

.

(3) Connect oscilloscope to

IC801 pin13 (H-OUT)

, adj

V03

until freq

become

15.625 ± 0.15 KHz.

(Auto Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode.

(3) Choose service data

V03

, by pressing R/C

Auto (Hex C1)

key, OSD will appear "OK"

at screen.

(4) If appear "NG" pls repeat step 3.

2 VIF-VCO ADJ

(Manual Adj)

*NOTE:

(I2C BUS CONTROL) (1) In No signal (RASTER) condition.

This adjustment must be done after aging

(2) Go to service mode, choose service data

V02.

at least 3 minutes.

(3) Connect oscilloscope to

IC801 pin7 (AFT)

, adj

V02

until voltage become

2.5 ± 1 V.

(Auto Adj)

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data

V02.

(3) Press the R/C

Auto (Hex C1)

key, OSD will appear "OK" at screen.

(4) If appear "NG" pls repeat step 3.

3 S-TRAP fo ADJ

(I2C BUS CONTROL) (1) In No signal (RASTER) condition.

(AUTO & MANUAL ADJ)

(2) Go to service mode, choose service data

V20.

(3) Connect oscilloscope to

TP 801

, adj

V20

until voltage become

Min

(below 5 V).

(4) After that pls adj service data

V19& V23 same as "V20", V21 to "V20+ 1", V22 to "V20-2".

(1) In No signal (RASTER) condition.

(2) Go to service mode, choose service data

V20 (S-TRAP I).

(3) Press the R/C

Auto (Hex C1)

key, OSD will appear "OK" at screen.

(4) If appear "NG" pls repeat step 3.

HORIZONTAL ,VERTICAL,DEFLECTION LOOP ADJUSTMENT (1)

NO

ADJUSTMENT POINT

ADJUSTMENT CONDITION / PROCEDURE WAVEFORM OR OTHERS

1 V-SHIFT (1) Receive Monoscope Pattern Signal (PAL 50 Hz). Figure A B

(I2C BUS CONTROL)

(2) Choose the service data

V12

.

(3) Adjust

V12

to align the center of the screen to the geometric center of CRT.

Note: B line (Monoscope middle line) must same or nearest higher position

to the A mark (Tube middle mark),refer to the attach drawing.

OK OK NG

2 V-SIZE (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V11

.

(to be done after V-shift adj)

(3) Adjust

V11

bus data until the overscan become

10 ± 1.5 %.

Caution 1: Pls aging TV more than 10 minutes before adjustment

3 V-LINEARITY (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V29

.

(3 )Already preset. (Adjust this unless the linearity is not achieved.)

4 VS CORRECTION (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V27

.

(3 )Already preset. (Adjust this unless the linearity is not achieved.)

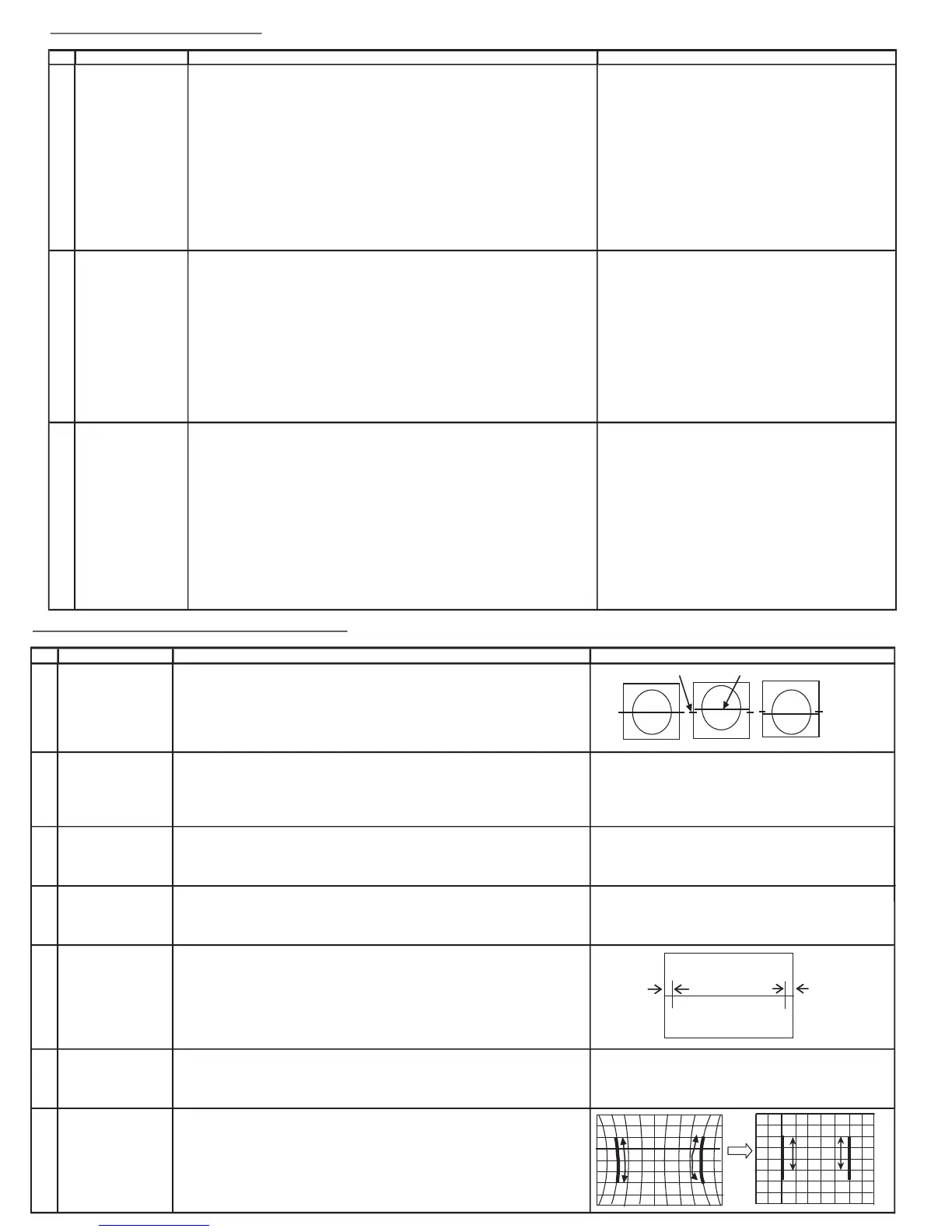

5 H-SHIFT (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V13

.

(3) Adjust the

V13

bus data to have a balance position to spec of

A=B

(as attach drawing).

A B

(4) If cannot make it to

A=B

, adjust from the best point so that

A

slightly smaller than

B

.

6 H-SIZE (1) Receive Monoscope Pattern Signal (PAL 50 Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V36

(3) Adjust

V36

bus data until the overscan becomes

10 ± 1.5 %.

7 PARABOLA (1) Receive CrossHatch Pattern Signal (PAL 50Hz).

(I2C BUS CONTROL)

(2) Choose the service data

V32

Adjust the 2nd vertical line from the right end of the crosshatch pattern

so that the middle 4 blocks are straight.

(3) Make sure both left / right of 2nd vertical line at optimum point

Loading...

Loading...