MECHANICAL ADJUSTMENT

TORQUE CHECK AT PLAY, FAST FORWARD AND

REWIND MODES

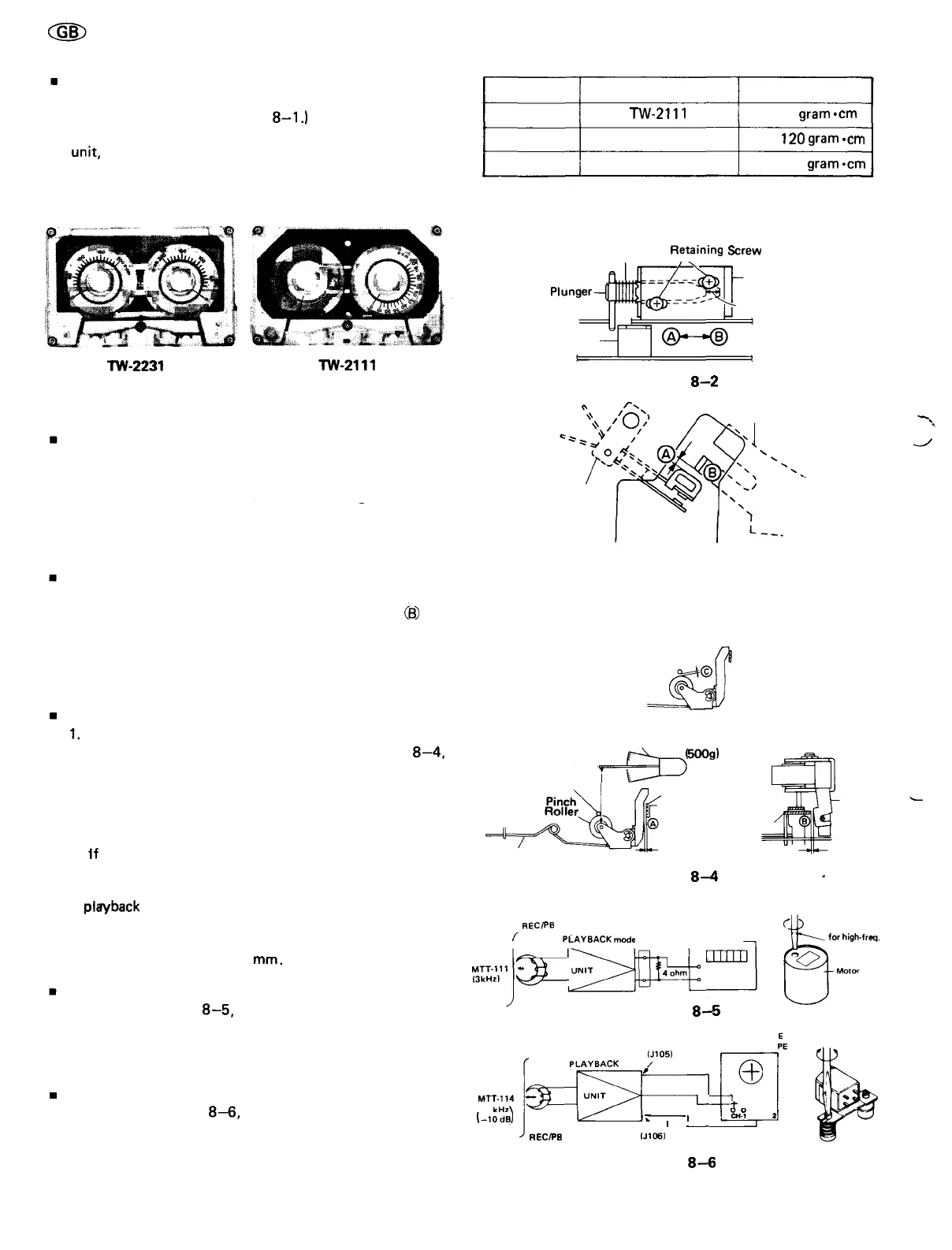

(Refer to Table 8-1 and Figure

8-1.)

Put a torque meter cassette in the cassette holder of the

unit,

and see

that

the

measured

torque

in

each

mode

is

normal as follows.

Mode

Play back

Fast-forward

Rewind

Torque meter cassette

TW-2111

TW-2231

TW-2231

Measured torque

35 ~ 60 gram

-cm

85 ~

120

gram

-cm

85 ~ 120 gram

-cm

Table 8-1

TW-2231

TW-2111

Figure 8-1

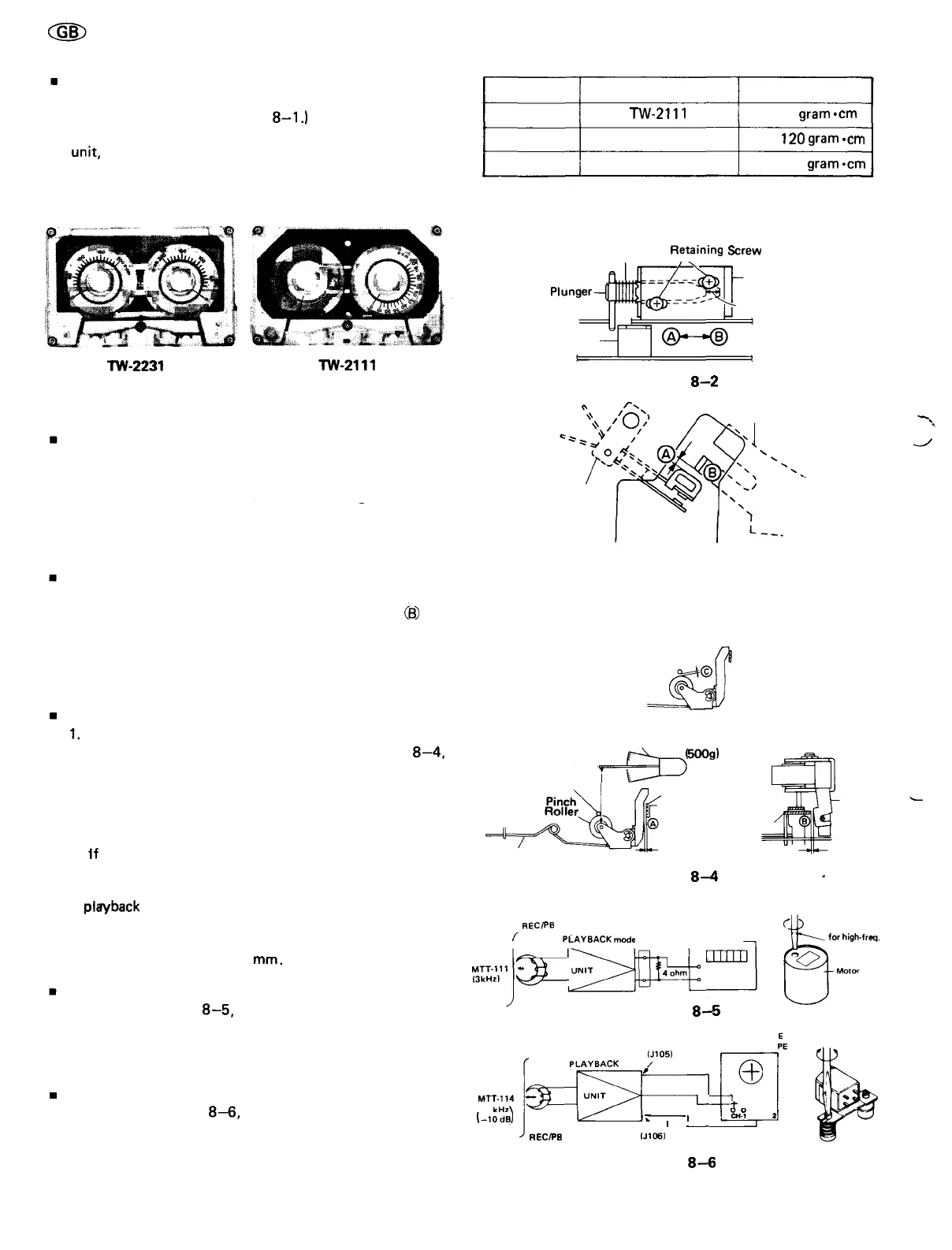

POSITIONAL ADJUSTMENT OF PLUNGER AND

SOLENOID

(Refer to Figure 8-2)

If the attractive stroke of the plunger is insufficient, adjust

it by shifting the solenoid in the direction (g) . If the at-

tractive force of the solenoid is insufficient, adjust it by

shifting the solenoid in the direction ® .

TIMING ADJUSTMENT OF APSS SWITCH

(Refer to Figure 8-3)

While the unit is in playback mode, bend the part

(B)

of

the sub chassis back lever to such degree that the clearance

® between the APSS switch and the sub chassis back

lever becomes about 1 mm. And check that the APSS

switch is turned on when the unit gets in APSS mode.

PINCH ROLLER PRESSURE CHECK

1.

Place the unit in playback mode.

2. Push the pinch roller, at the point shown in Figure

8—4,

by using a tension gauge (500 g) so that it will come off

the

capstan.

Then,

slowly

release

the

tension

until

the

pinch roller hits the capstan again (i.e., the pinch roller is

about to rotate again). Check, then, the tension gauge is

reading 270 g to 370 g.

3.

If

the reading is outside the range of 270 g to 370 g,

replace the pressure spring of the pinch roller.

Notes:

In

playback

mode, make sure that the clearance (g) and the

clearance (g) are more than 0.2 mm and more than 0.1 mm

respectively. Next in pause mode, make sure that the

clearance © is more than 0.3

mm.

TAPE SPEED ADJUSTMENT

As shown in Figure

8—5,

make connection of instrument,

put a screwdriver (for high-frequency use) into the hole of

the motor, and adjust the variable resistor so that the

output frequency is 2960 to 2985 Hz on frequency counter.

RECORD/PLAYBACK HEAD AZIMUTH ADJUSTMENT

As shown in Figure

8—6,

make connection of instrument,

and adjust the head azimuth adjusting screw so that the

output signals from both channels will have maximum

waveform with the same phase in right and left.

Spring

Retaining

Screw

Plunger—I

APSS Release

Lever

Solenoid

Attractive Stroke

Figure

8—2

Sub Chassis

Back Lever

APSS

Switch

Figure 8-3

Tension Gauge

(500g)

Capstan

^D'

Pause

Lever

Sub Chassis

Pinch Roller

Pressure Spring

-Pinch

Roller

Figure

8-4

EXT.

SP

REC/PB

(J10S. 106) FREQUENCY

Л

HEAD

PLAYBACK

mode

/ COUNTER

TEST TAPE

MTT-111

13kHz)

^S-

Figure

8-5

Screwdriver

for

high-freq.

use

TEST TAPE

MTT-114

/10

kHz\

(-10dB)

REC/PB

HEAD

EXT.

SP

IJ105)

LAYBACK

mode

,

GROUND

L_

I

——————

I

\

I

———

IJ106)

EXT.

SP

DUAL TRAC

SYNCROSCO

Ф

]

i i

о

4

сн°

Т си

2

Figure

8—6

-8-

Loading...

Loading...