13

VC-A592U/A593U

VC-A5933U/H992U

VC-H993U/H994U

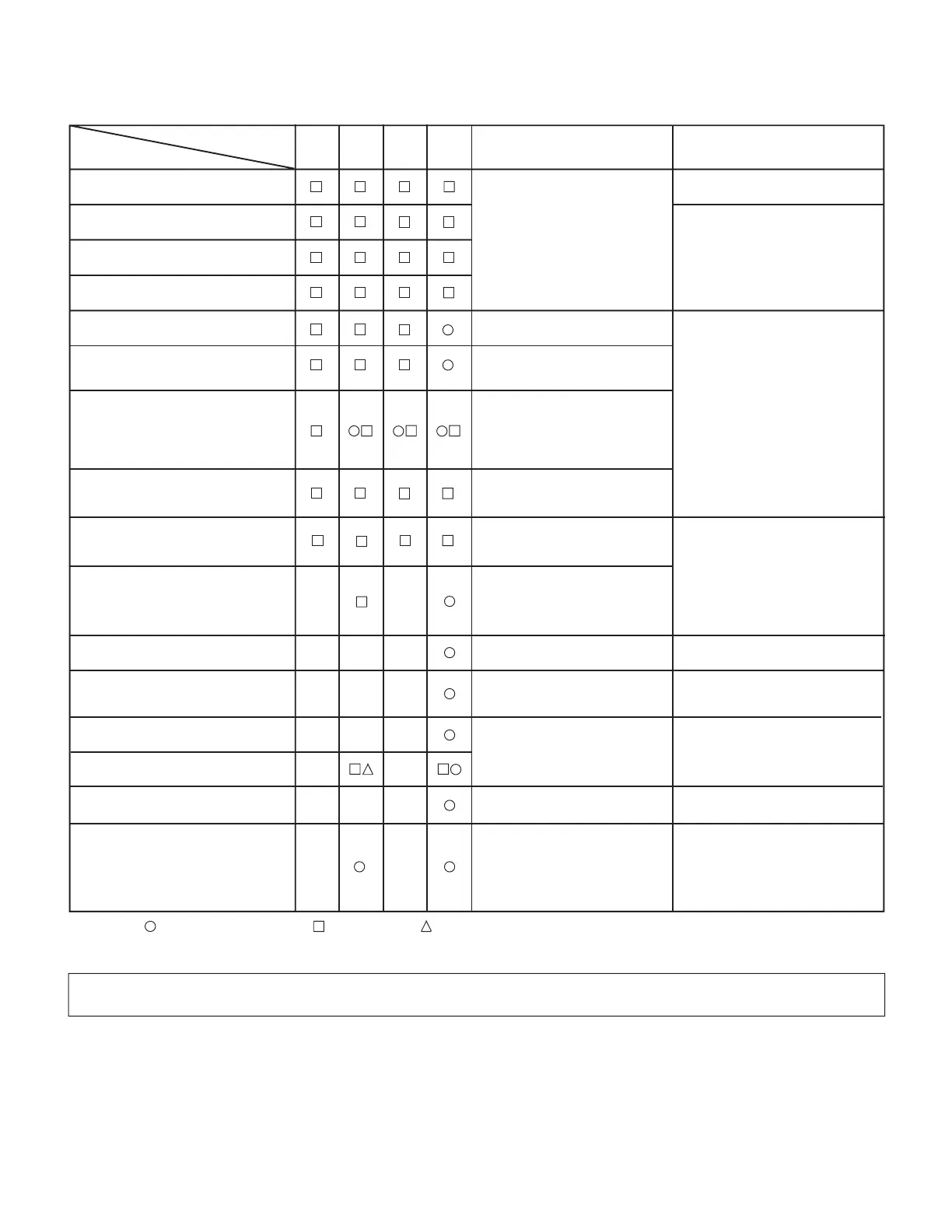

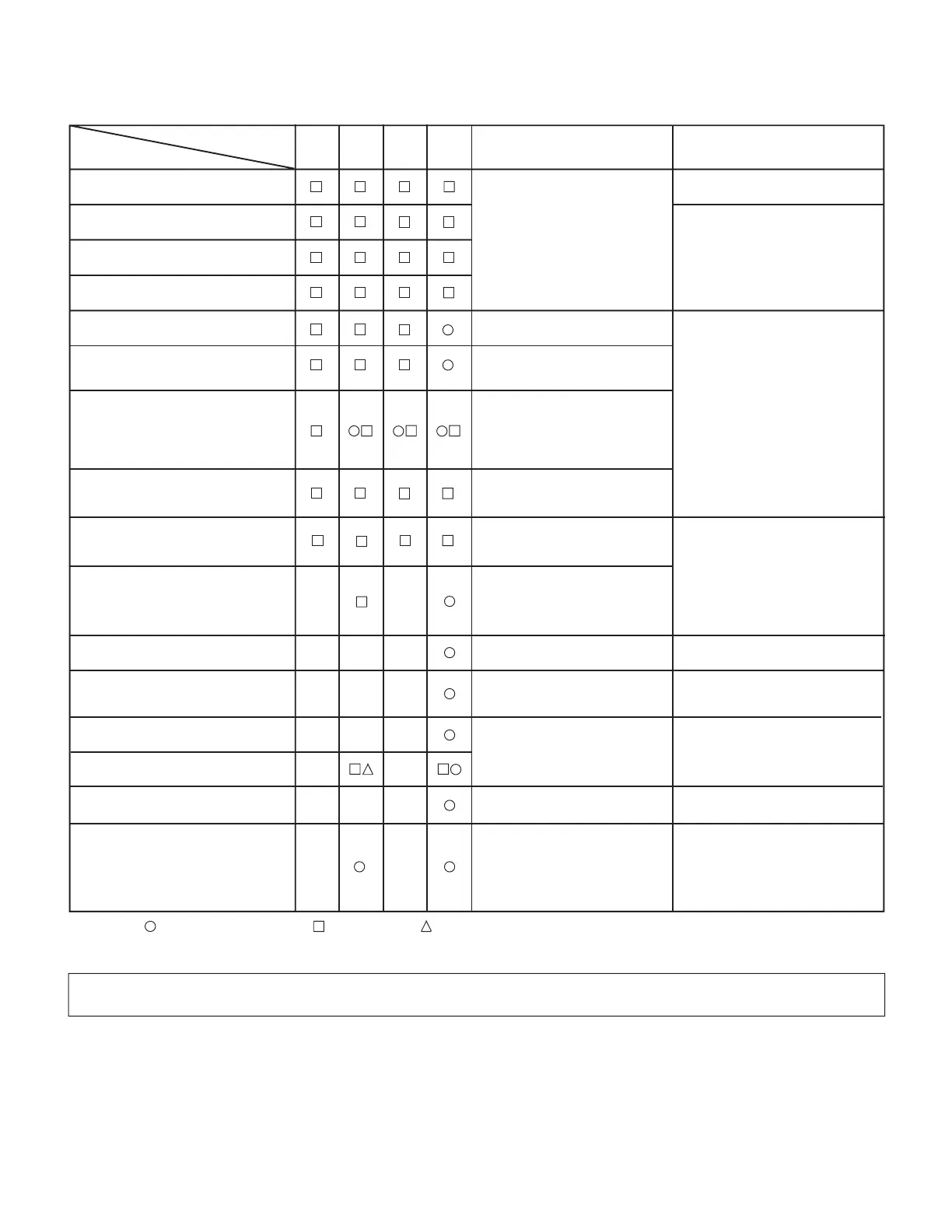

MAINTENANCE CHECK ITEMS AND EXECUTION TIME

Perform the maintenance with the regular intervals as follows so as to maintain the quality of machine.

Parts

Maintained

500

hrs.

1000

hrs.

1500

hrs.

2000

hrs.

Remarks

Possible symptom

encountered

Upper and lower drum ass’y

Pinch roller

Capstan D.D. motor

Reel belt

Idler ass’y

Tension band ass’y Screen swaying

Loading motor

Limiter pulley

Supply/take-up main brake levers Tape slack

A/C head

Guide roller ass’y

Sup guide shaft

Reverse guide

Slant pole on pole base

Full erase head Colour and beating

Lateral noises Head

occasionally blocked

Small sound or sound dis-

tortion

Poor S/N ratio, no colour

Poor flatness of the envelope

with alignment tape

Cassette not loaded or un-

loaded

No tape running, tape

slack

Clean tape contact part with

the specified cleaning liquid.

Abnormal rotation or significant vi-

bration requires replacement.

Clean rubber and rubber

contact area with the speci-

fied cleaning liquid.

Clean tape contact area with

the specified cleaning liquid.

No tape running, uneven col-

our

No tape running, tape

slack, no fast forward/re-

wind motion

No tape running, tape

slack

Replace the roller of the

cleaner when it wears down.

Just change the AHC roller

assembly for new one.

AHC(Automatic head cleaner)

NOTE: : Part replacement. : Cleaning : Apply grease

<Specified> Cleaning liquid Industrial ethyl alcohol

* This mechanism does not need electric adjustment with variable resistor. Check parts. If any deviation is found, clean

or replace parts.

Loading...

Loading...