4-3

VL-E610S/VL-E610H

VL-E660S/VL-E96E

VL-E98E

4-2. Items and timings of inspection and maintenance

The mechanism of VCR needs the following periodic inspection and maintenance in order that it maintains its high quality. Also,

after the machine is repaired, execute the following maintenance and checks regardless of how long it has been used.

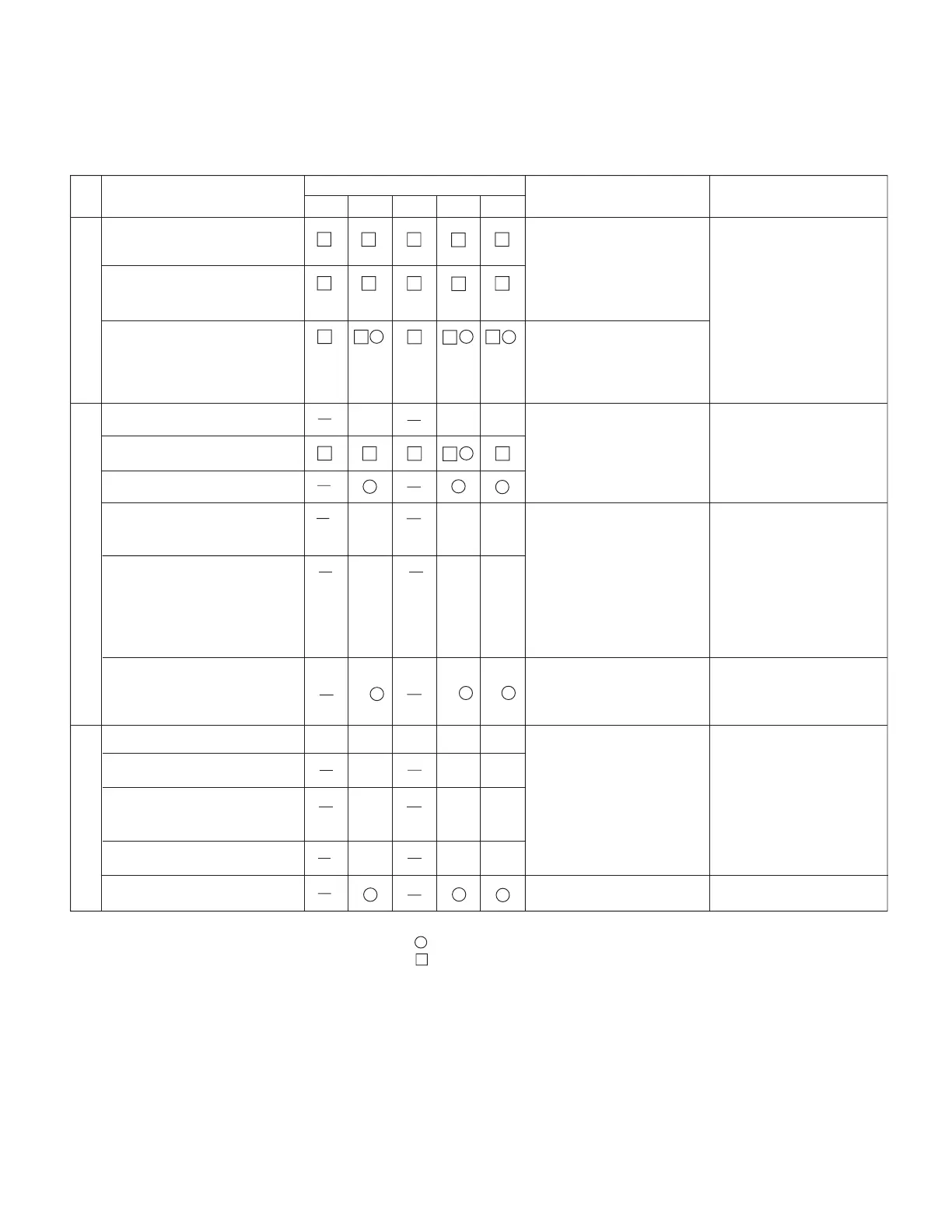

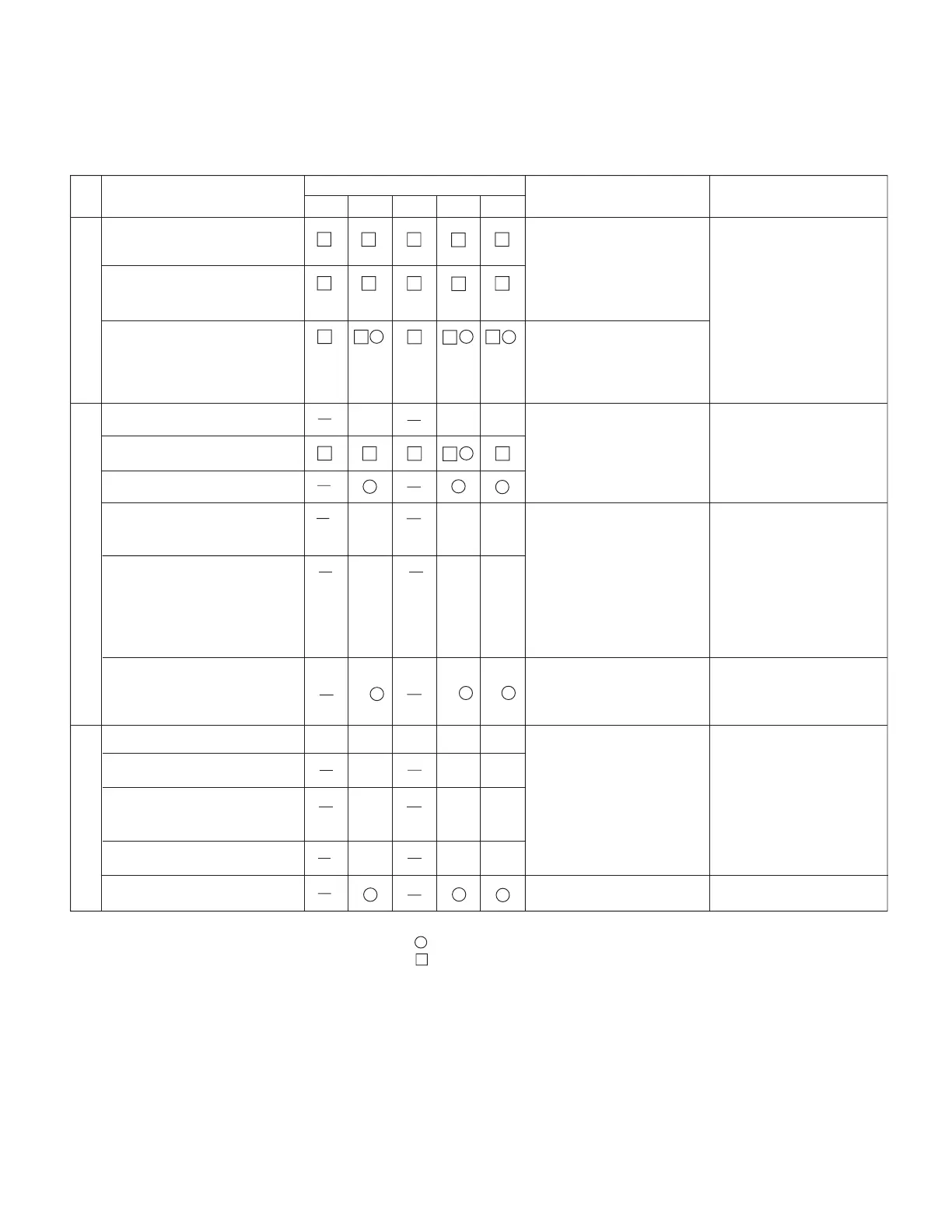

4-2-1. Inspection and maintenance list

Checking/Maintenance point

Tape travelling route

(Refer to Section)

Drum (Refer to Section)

Remarks

Rollers

• If abnormal rotation or

deflection (signifi-

cant) is found, replace

the roller.

Other than rollers

• Clean the tape con-

tacting areas. Be sure

to use the specified

cleaning agent.

Possible symptom

encountered

• Lateral noise

• Unclean head

• Screen shaking

• Improper S/N ratio

• No color appears.

Video head

Usage time (hrs.)

500 1,000 1,500 2,000 3,000

Tape travel system

Timing belt

Pinch roller

Capstan D.D. motor

Relay Pulle shaft

Pulle gear shaft

Drive gear shaft

• Tape does not run.

• Tape slackens.

• Screen shakes.

• Abnormal sound

• Apply oil.

(Oil: COSMOHYDRO

HV100)

• Replace if failure is

found.

★★★

∆∆∆

Driving system

∆∆∆

Loading motor

• Replace if failure (ab-

normal sound) is de-

tected.

Abnormal sound

PB/VS-REW take-up torque

PB/VS-REW back tension

torque

Tu brake

• Not ejectable

• The specific mode can-

not be set.

• If conformance to the

standard is not en-

sured, replace part.

★★★★★

★★★

★★★

★★★

★★★

Performance check

Note:

After oil is applied to

the drive gear shaft,

slightly wipe it off with

swab.

HC (Head Cleaner)

Oil: COSMOHYDRO, HV100

Grease: MORYCOAT YM-103/X5-6020

Screw locking agent: THERE BOND 1401B

Cleaning liquid: Industrial-use ethyl alcohol

∆ : Apply oil.

★ : Check.

: Replace.

: Clean.

Loading...

Loading...