VL-E780U

VL-E785U

VL-E785T

4

5. MECHANISM ADJUSTMENT

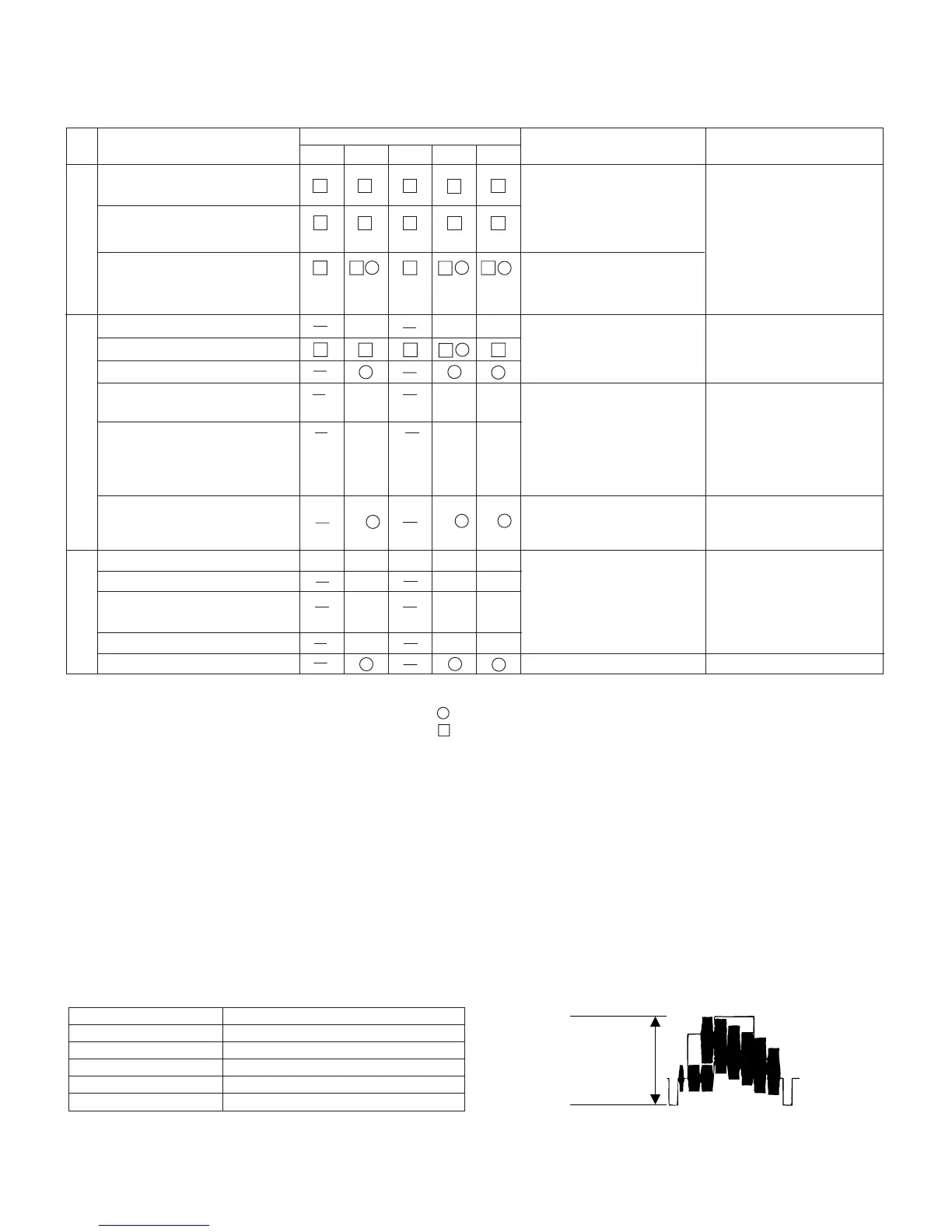

5-2. Items and timings of inspection and maintenance

5-2-1. Inspection and maintenance list

Checking/Maintenance point

Tape travelling route

(Refer to Section)

Remarks

Rollers

• If abnormal rotation or

deflection (significant) is

found, replace the roller.

Other than rollers

• Clean the tape contact-

ing areas. Be sure to

use the specified clean-

ing agent.

Possible symptom

encountered

• Lateral noise

• Unclean head

• Screen shaking

Usage time (hrs.)

500 1,000 1,500 2,000 3,000

Drum (Refer to Section)

• Improper S/N ratio

• No color appears.

Video head

Tape travel system

Timing belt

Pinch roller

Capstan D.D. motor

• Tape does not run.

• Tape slackens.

• Screen shakes.

★★★

• Replace if failure is

found.

Relay Pulle shaft

Pulle gear shaft

Drive gear shaft

∆∆∆

∆∆∆

• Abnormal sound

• Apply oil.

(Oil: )

Note:

After oil is applied to the

drive gear shaft, slightly

wipe it off with swab.

Loading motor

• Replace if failure (abnor-

mal sound) is detected.

• Not ejectable

• The specific mode can-

not be set.

Driving system

★★★

Abnormal sound

PB/VS-REW take-up torque

PB/VS-REW back tension

torque

Tu brake

★★★★★

★★★

★★★

★★★

HC (Head Cleaner)

Performance check

• If conformance to the

standard is not ensured,

replace part.

Oil:

Grease: MORYCOAT YM-103/X5-6020

Screw locking agent: THERE BOND 1401B

Cleaning liquid: Industrial-use ethyl alcohol

: Replace.

: Clean.

∆ : Apply oil.

★ : Check.

5-4. ADJUSTMENT OF MECHANISM TAPE TRAVEL SYSTEM

5-4-3. Adjusting the Si roller height

(2) Adjusting the Si roller

1 Playback the tape such as to set the V/SR mode.

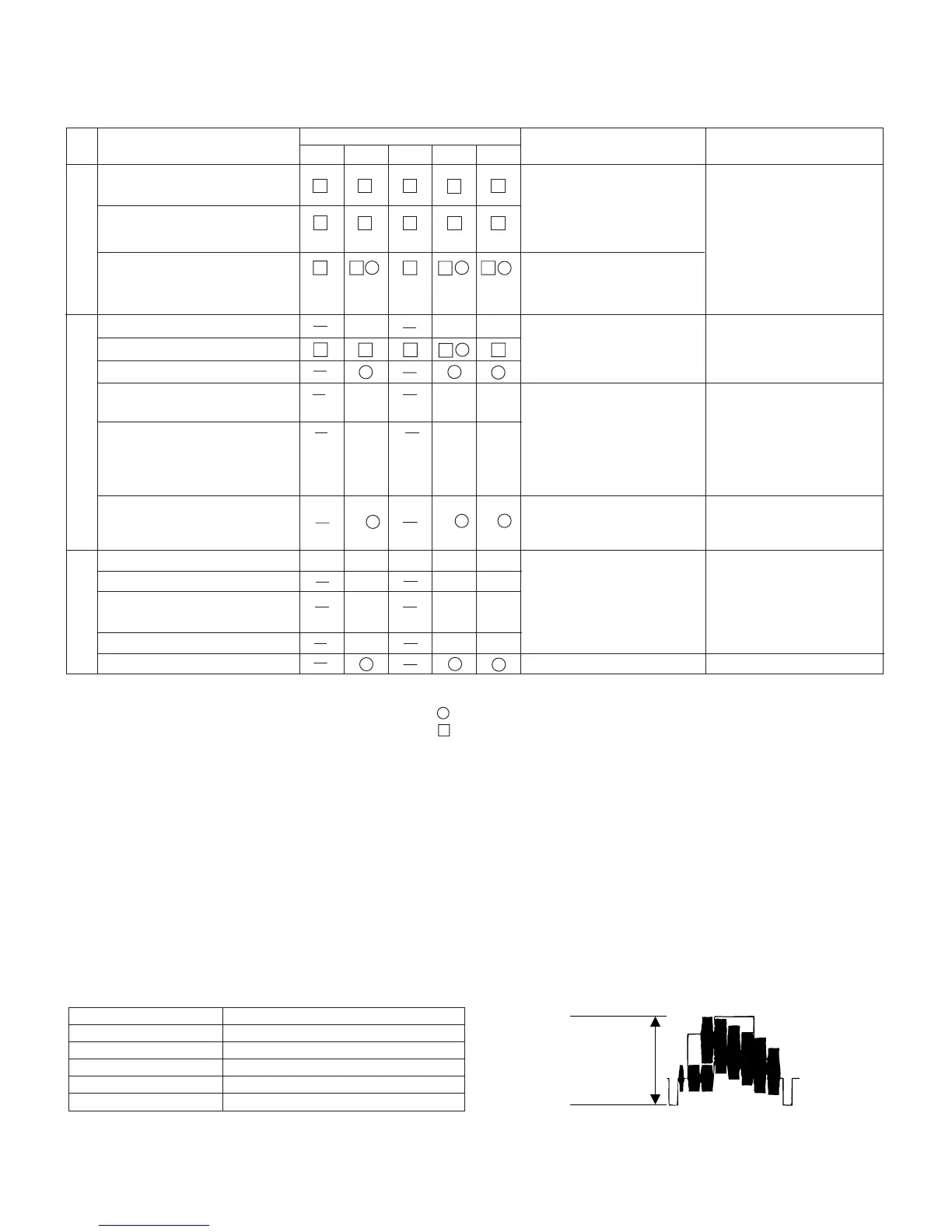

6. ADJUSTMENT OF VCR

6-1. ADJUSTMENT OF VCR SECTION

6-1-5. Y/C circuit adjustment method

2. Adjustment of input Y level

Measuring instrument Oscilloscope

Mode VCR STOP

Input signal Color bar

Measuring point TL801

Adjustment address 32

Adjustment level 500 Vp-p ± 20 mVp-p

Loading...

Loading...