L-PDl U

7. MECHANICAL ADJUSTMENTS AND CHECKS .

The items discussed here relate to general on-site servicing (field servicing). Adjustments and replacements that require

sophisticated facilities, jigs and technology are omitted.

In addition, in order to maintain the characteristics that the unit has when it is new, not only are inspection and maintenance

necessary, but it is absolutely necessary that, for example, the tape not be damaged, and always use jigs for adjustments

that require them.

<Precautions>

(1) Always set the power supply and state of the unit as follows for mechanism adjustments and checks.

AC adapter used, with cassette controller assembly 1

07-l Checking the playback (recording) winding torque

07-4 Back tension torque check and adjustment in record (playback) mode

1 AC adapter used, without cassette controller assembly (independent Mechanism) 1

07-2 Checking the rewinding playback (VS-REW) winding torque

DC3V, without cassette controller assembly (Independent Mechanism)

07-3 Checking of reel base height

07-5 Checking and adjustment of tension roller position in record (playback) mode

07-6 Checking of supply S reel base no-load torque

07-7 Checking of loading back tension

07-8 Checking of winding Tu reel base ratchet torque

07-9 Checking of rewinding playback (VS-REW) back tension

l 7-10 Checking of pinch pressing force

(2) When performing checks with a DC3V power supply and independent mechanism, disconnect the loading motor

FPC from the connector.

(3) Always run the tape with the cassette controller assembly attached.

7-1. Checking the ptayback (recording) winding torque

(l)Set the torque cassette with the cassette controller assembly attached, then, in SP recording mode (playback mode

if a signal has already been recorded in SP mode on the tape), confirm that the torque on the winding side is within the

standard.

Winding torque standard-in record (playback) mode

0.70 * 0.35mNm (7.0 + 3.5gfcm),

ripple 0‘.2mN*m (2gfcm) or less

(If there is torque ripple, read the center value.)

7-2. Checking. the rewinding playback (VS-REW) winding torque

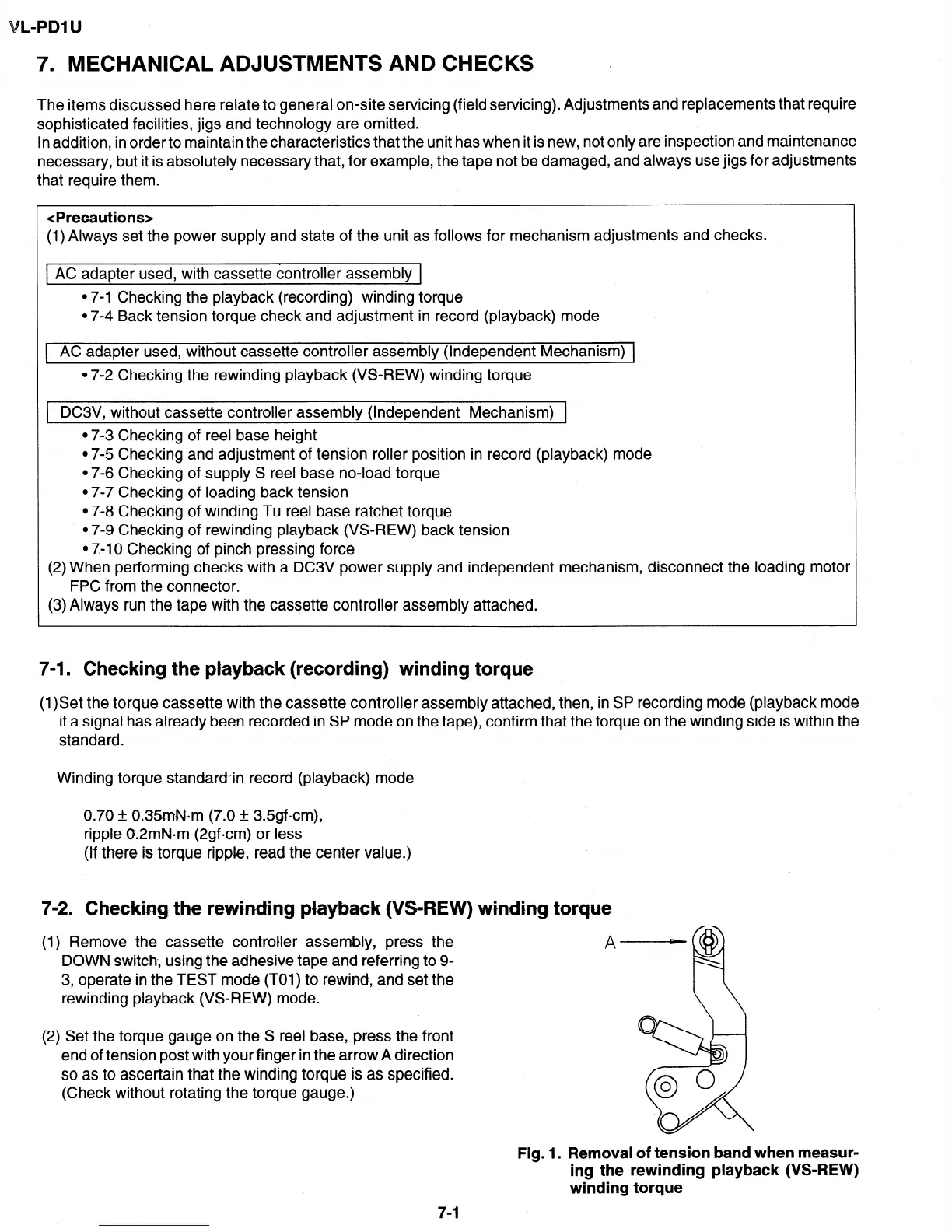

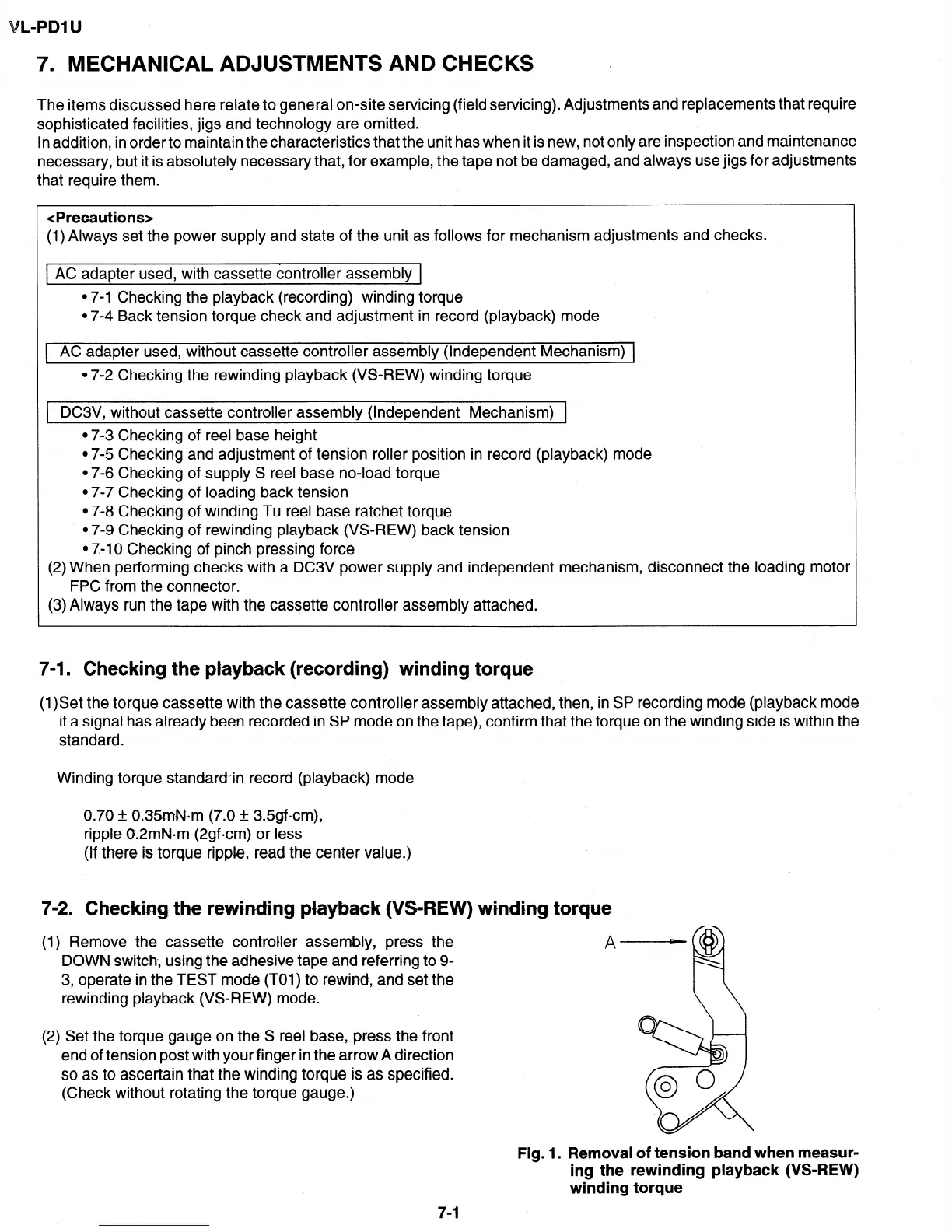

(1) Remove the cassette controller assembly, press the

DOWN switch., using the adhesive tape and referring to 9-

3, operate in the TEST mode (TOl) to rewind, and set the

rewinding playback (VS-REW) mode.

(2) Set the torque gauge on the S reel base, press the front

end of tension post with your finger in the arrow A direction

so as to ascertain that the winding torque is as specified.

(Check without rotating the torque gauge.)

Fig. 1.

Removal of tension band when measur-

ing the rewinding playback (VS-REW)

winding torque

7-l

Loading...

Loading...