VL-PDl U

8-4. Running rough adjustment

(Since this adjustment is performed without cassette controller, put a proper weight so that the cassette does not rise ,

and make an adjustment.)

Adjustment item

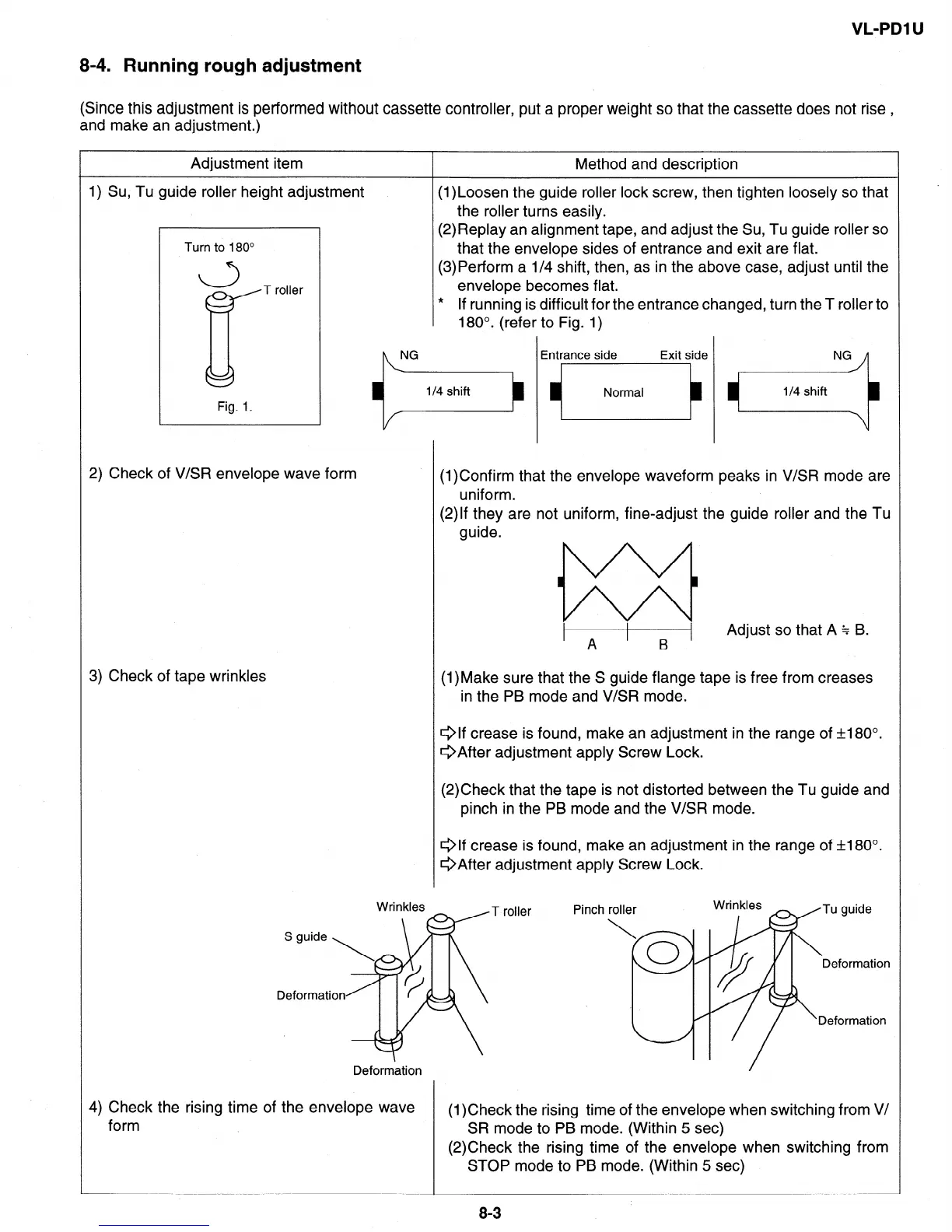

1) Su, Tu guide roller height adjustment

Method and description

(l)Loosen the guide roller lock screw, then tighten loosely so that

the roller turns easily.

Turn to 180”

a

c

T roller

(2)Replay an alignment tape, and adjust the Su, Tu guide roller so

that the envelope sides of entrance and exit are flat.

(3)Perform a l/4 shift, then, as in the above case, adjust until the

envelope becomes flat.

* If running is difficult for the entrance changed, turn the T roller to

180”. (refer to Fig. 1)

2) Check of V&R envelope wave form

(l)Confirm that the envelope waveform peaks in V/SR mode are

uniform.

(2)lf they are not uniform, fine-adjust the guide roller and the Tu

guide.

1

A

Adjust so that A $ B.

B

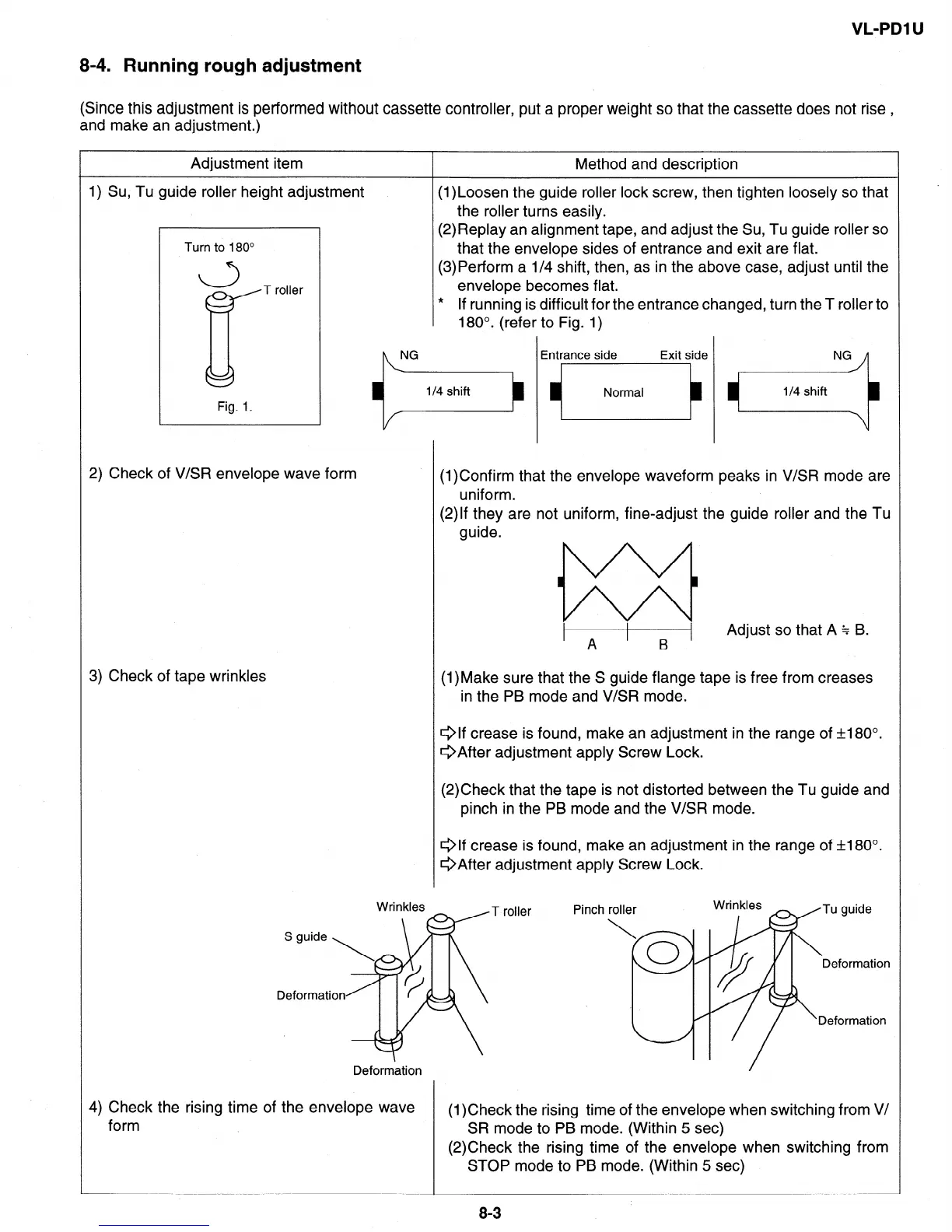

3) Check of tape wrinkles

(l)Make sure that the S guide flange tape is free from creases

in the PB mode and V/SR mode.

elf crease is found, make an adjustment in the range of f180°.

@After adjustment apply Screw Lock.

(2)Check that the tape is not distorted between the Tu guide and

pinch in the PB mode and the V/SR mode.

Qlf crease is found, make an adjustment in the range of t180”.

QAfter adjustment apply Screw Lock.

Deformation

T roller

Pinch roller

Wrinkles

~

Tu guide

\

0

//

Deformation

‘q // ‘Deformation

4) Check the rising time of the envelope wave

form

(1)Check the rising time of the envelope when switching from V/

SR mode to PB mode. (Within 5 set)

(2)Check the rising time of the envelope when switching from

STOP mode to PB mode. (Within 5 set)

83

I

Loading...

Loading...