SECTION 3 – LUBRICATION AND MAINTENANCE

3-30

FRONT-WHEEL DRIVE

FRONT AXLE DIFFERENTIAL/FINAL

REDUCTION GEAR CASE

Checking the Front Axle Differential/Final

Reduction Gear Case Oil Levels

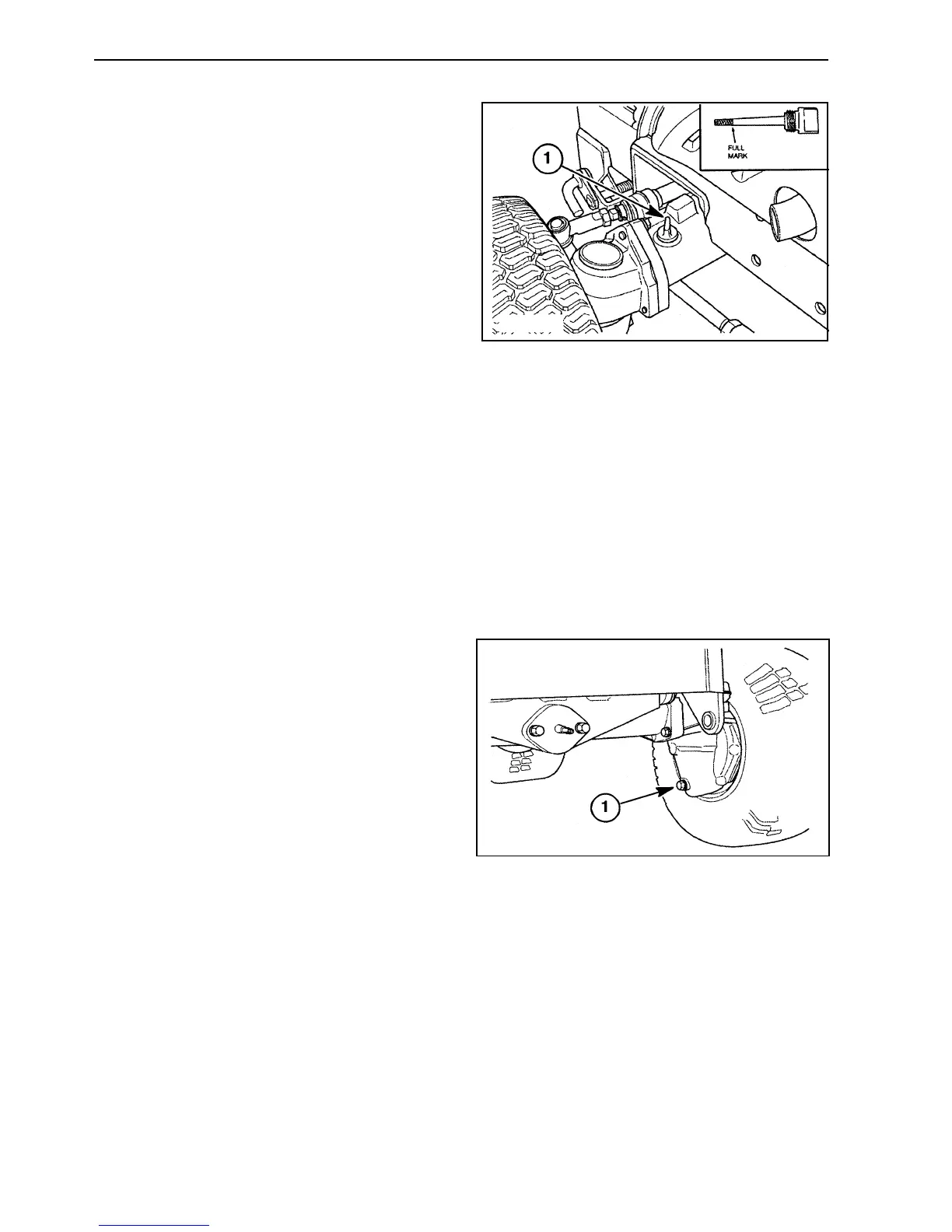

NOTE: Check the oil level in the combined front

axle differential/final reduction gear case after

every 50 hours of operation.

1. With the tractor standing level and the

engine off, check the front axle oil level using

the dipstick/filler plug ①.

2. The oil is at the correct level when it reads

between the 'full' mark and the lower end of

the dipstick. If the oil level is low, add SAE

80 hydraulic oil through the combined

dipstick/filler opening. Do not fill beyond the

dipstick 'full' mark, or the front axle will be

overfilled.

NOTE: To obtain the correct oil level reading, do

not screw the dipstick into the axle case, when

checking the oil level.

3. Reinstall the dipstick/filler plug.

Changing the Front Axle Differential/Final

Reduction Gear Case Oil

NOTE: The oil in the combined front axle

differential/final reduction gear case should be

changed after every 300 operating hours.

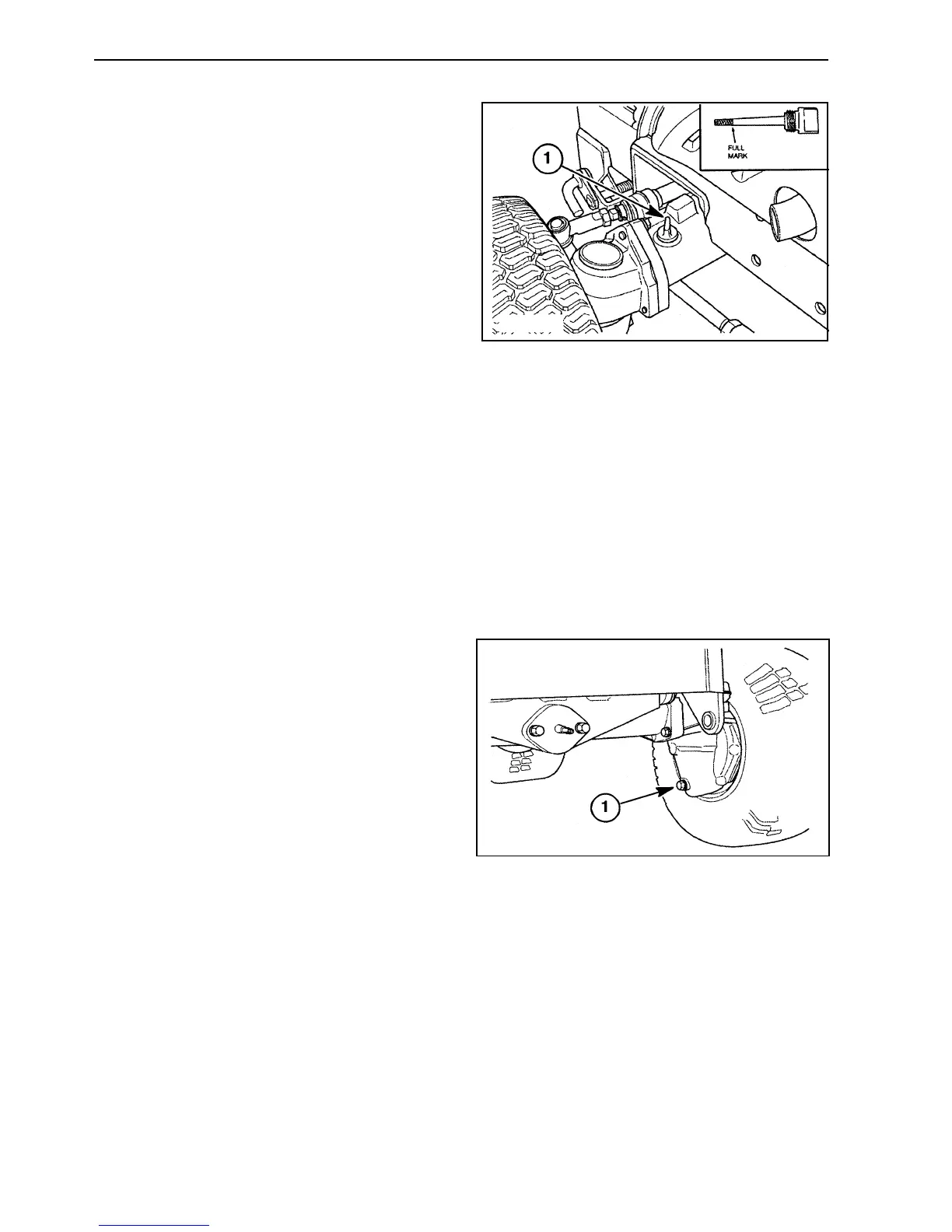

1. Place a suitable container beneath the oil

drain plugs ① located at the bottom of the

final reduction gear housings on both sides

of the tractor.

NOTE: The capacity of the combined front axle

differential/final reduction gear case is 2.0L of

hydraulic oil.

2. With the oil at normal operating temperature,

remove the dipstick/filler plug ② and both

drain plugs and allow the front axle case to

completely drain.

Loading...

Loading...