-17-

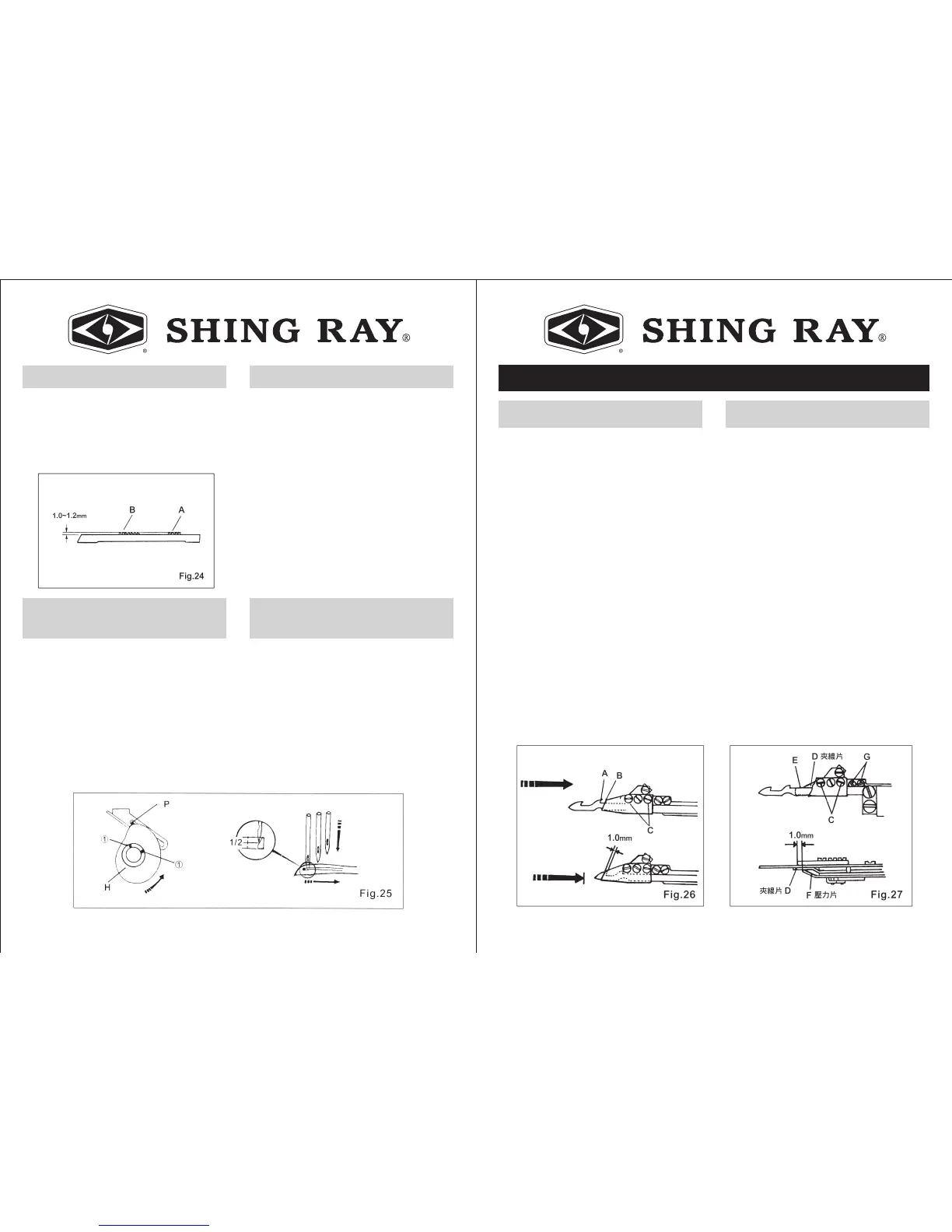

送布齒在最高位置時,送布齒齒尖面

與針板面平行,且此時主送布齒(A)與

差動送布齒(B),高度相同,且齒面高

出針板面1.0~1.2mm。(圖24)

H 送布齒高度調整:

When the Feed Dog rise up to the

highest position, the surface of Feed

Dog and Needle Plate must be in

parallel. Besides, the teeth of Main and

Differential Feed Dog must be aligned.

The standard height of Feed Dog is

about 1.0˜1.2mm from its top teeth to

Needle Plate. (Fig. 24)

H.

ADJUST THE HEIGHT OF FEED DOG :

1. 當針從最高點下降時,左針大約位於

勾針後面之一半的位置時(圖25),勾

針線必須脫離凸輪(P)之最高位置。

2. 須調整凸輪時,放鬆22個螺絲(1)調

整之。

I 勾針控線凸輪之調整:

1. When Needle comes down from the

highest position, and the left Needle

reaches around 1/2 position of the

Looper. (Fig. 25)

The looper thread will come over the

highest position of Thread Cam (P).

2. Loosen the two screws (1) for above

adjustment.

I.

THE ADJUSTMENT OF

LOOPER THREAD TAKE-UP :

-18-

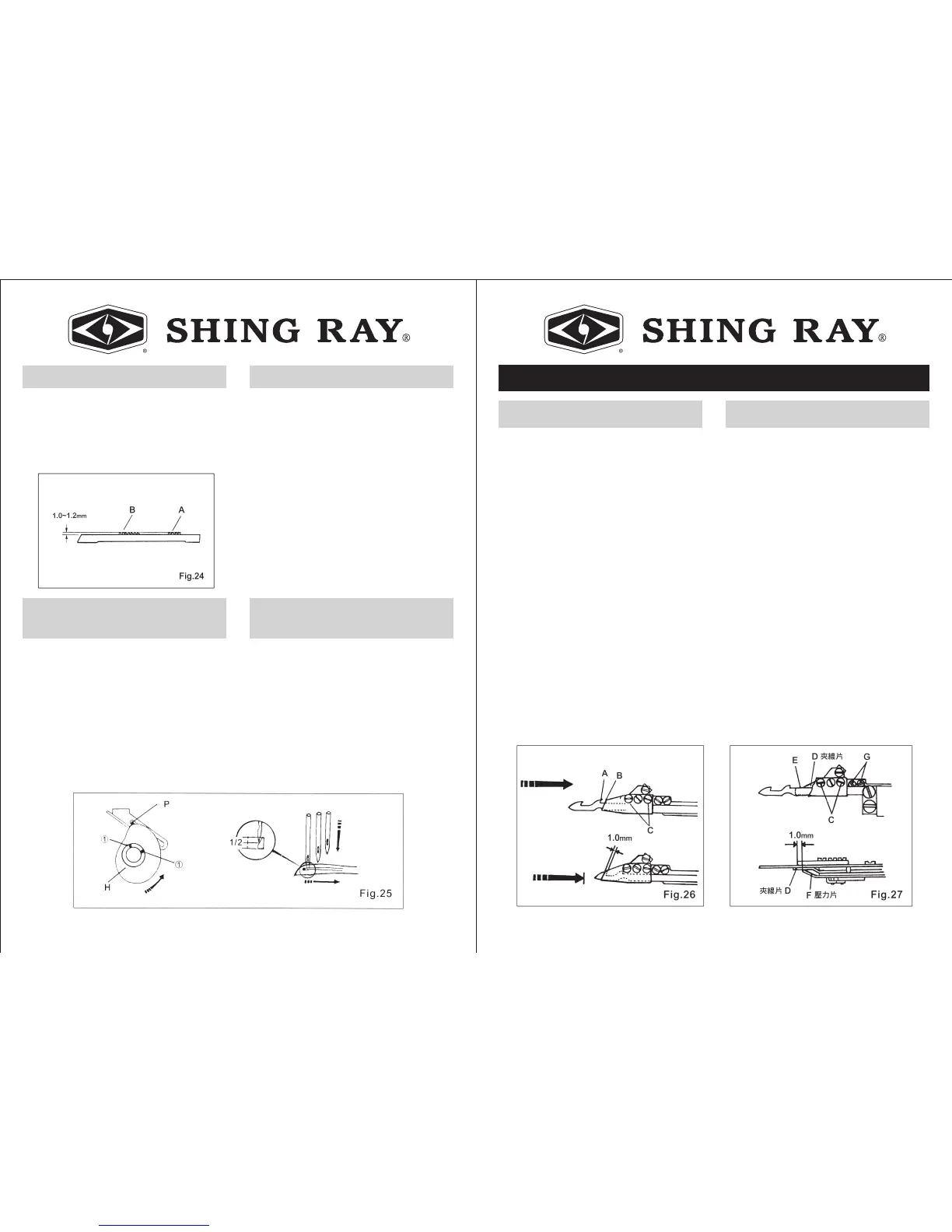

注意:

下切刀組安裝於機器前須先檢查切刀

組之相關位置和滑順度及切線效果。

1. 當活動刀片往右移時,右邊刀口之尖

端(A)與固定刀之前端(B)須對齊。

且活動刀移至最右點時,左邊刀口

和固定刀前端的契合度為1.0mm。

調整時可放鬆螺絲(C)移動固定片。

(圖26)

2. 夾線片(D)之邊沿須與活動刀右邊刀

口內沿切齊,如(E)。可由螺絲(C)調

整。壓力片(F)前端與固定刀前端之

距離約為1mm,調整時,可放鬆螺

絲(G)移動壓力片(F)。(圖27)

A 下切刀組相關位置調整:

Remark :

Before you install the new Trimmer set into

machine, Please always to check the relative

position, the situation of sliding and the

trimming effect﹒

1. When Lower Moving Knife move to the right,

the Moving Knife hook (A) of right hand side

one align with the tip (B) of Fixing Knife. When

the Lower Moving Knife move to the right dead

point, The Moving Knife hook of left hand side

one pass the tip of Fixing Knife in 1.0mm. Loosen

the screw (C) for adjusting the position of Fixing

Knife. (Fig.26)

2. The edge of Clamp Spring (D) align with the

inside edge of Moving Knife of right hand side

hook (E). Please loosen the screw (C) to adjust

the position of Clamp Spring and Fixing Knife.

The distance between the top of Clamp Spring

Pressure and top of Fixing Knife is about 1mm.

Please loosen the screw (G) to adjust the position

of Clamp Spring Pressure. (Fig.27)

A

. THE RELATIVE POSITION ADJUSTMENT OF

BOTTOM TRIMMER CUTTING PARTS.

自動切線調整說明

AUTO THREAD TRIMMER ADJUSTMENT GUIDE :

Loading...

Loading...