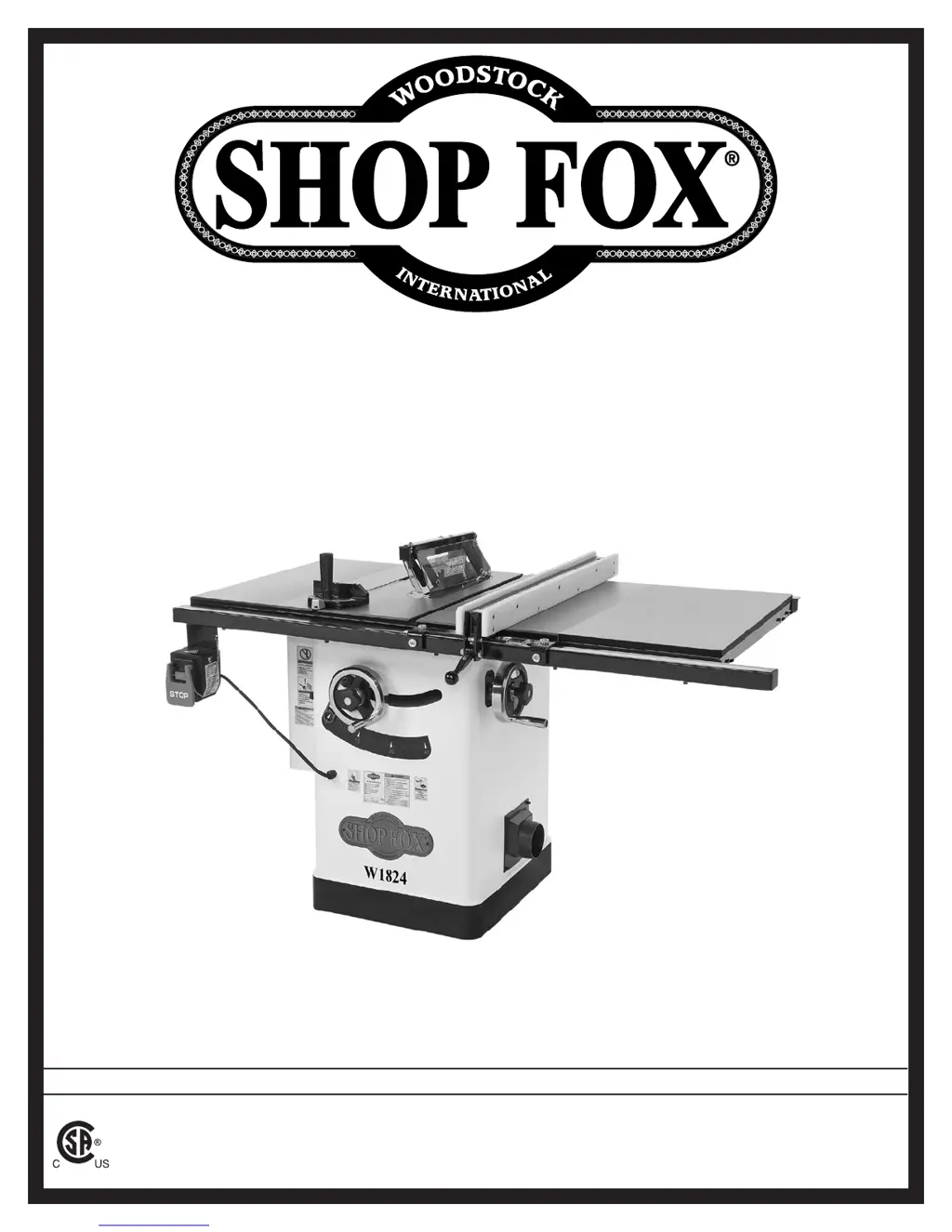

What to do if my Shop fox W1824 Saw does not start?

- TTodd PowellJul 30, 2025

If your Shop Fox Saw does not start or a breaker trips, there are several potential causes. First, make sure the locking pin is removed from the START button. Check for a blown fuse and replace it, ensuring there are no shorts. If the wall circuit breaker has tripped, ensure the circuit size is correct and replace any weak breakers. Verify that the power supply is switched ON and has the correct voltage. Test the plug/receptacle for good contacts and correct the wiring if necessary. Check and correct the motor wiring connections. Inspect for any broken, disconnected, or corroded wires and fix them. If the motor START/STOP switch is faulty, replace it. Test and replace the start capacitor if it is at fault. Finally, test, repair, or replace the motor if necessary.