Sicma S.p.A.

Miglianico (CH)

page 25

MAINTENANCE OF THE MACHINES

FIRST CHECK

- Check the correct tension of the driving belt *

- Check that all bolts and nuts are tightened strongly *

- After the first 50 hours of work change oil in the overgear unit *

EVERY 8 HOURS OF WORK

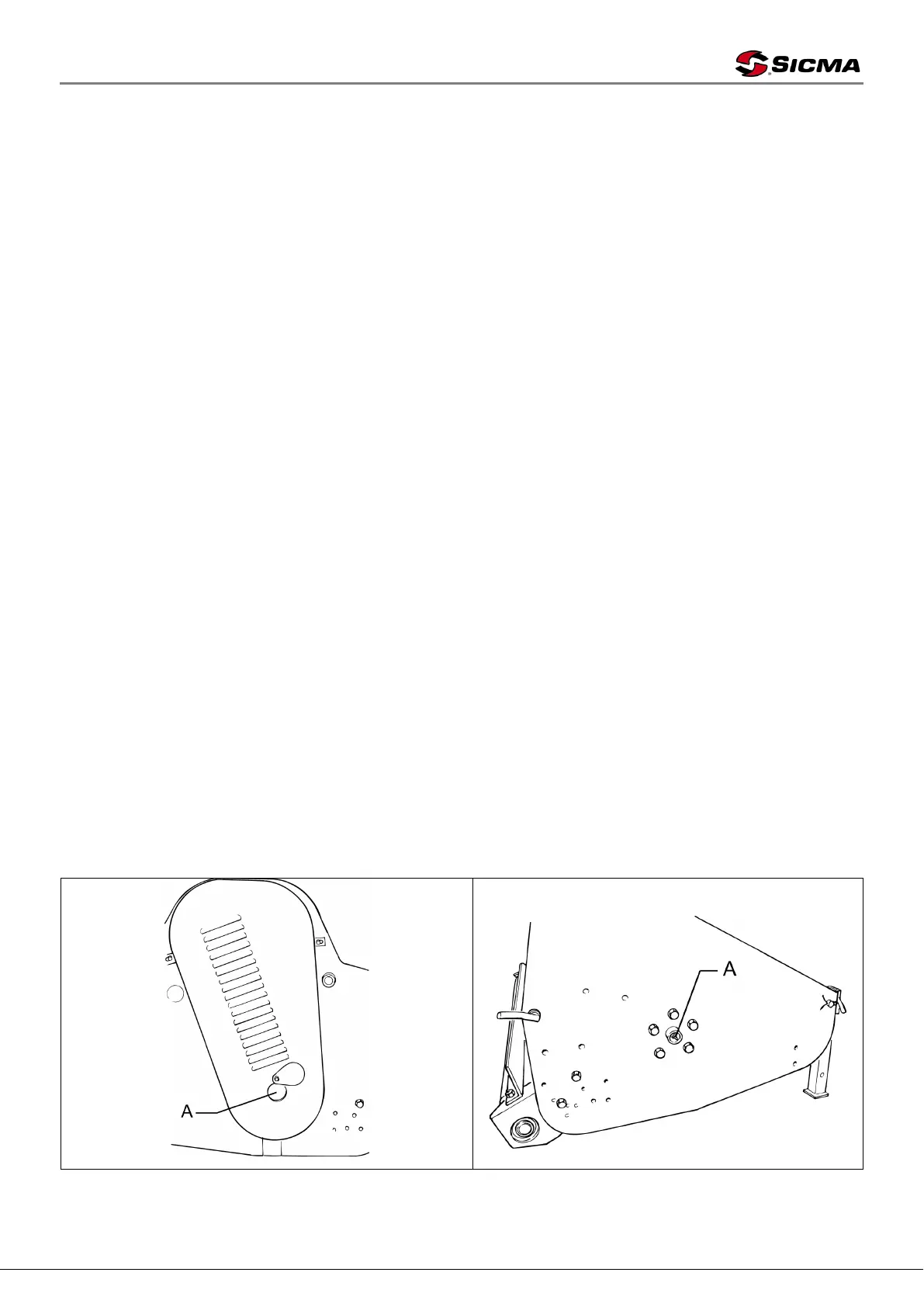

- Grease the shaft support (driveline side) through the lubricating nipple A (picture 20)

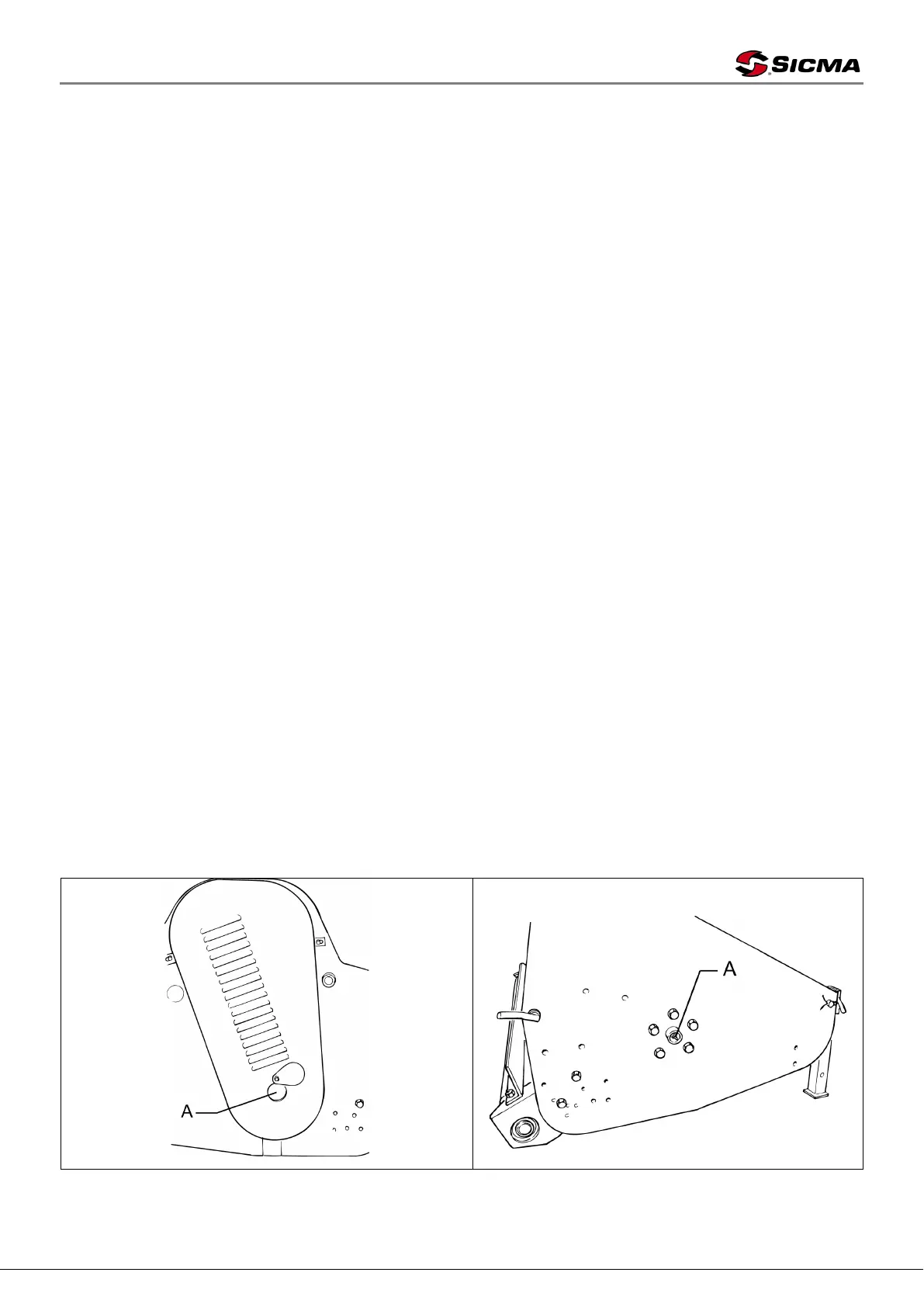

- Grease the shaft support (external side) through the lubricating nipple A (picture 21)

- Grease the shaft support (driveline) (TA, TMX, TLX-R, TSD, TE, SL) through the lubricating

nipple A (picture 22)

- Grease the stabilizing roller through the lubricating nipple A (picture 23)

- Grease the side shift rods through the lubricating nipple A (picture 24 - TMX, TR, TRX, TE -

and picture 25 - TSP - )

- Grease the cardan shaft spiders on gearbox (TR, FB, TSD); do as follows (picture 26):

- screw out wing nuts A and remove safety guard B;

- grease the spiders through lubricating nipple (see the cardan shaft manual);

- after greasing replace safety guard B and tighten wing nuts A strongly.

EVERY 50 HOURS OF WORK

- Check the correct tension of the collection rotor gearing chain (only TSD) and lubricate *

- Check the correct tension of the driving belt *

- Check that all bolts and nuts are tightened strongly *

- Check the cutters/hammers wear state

- Check the overgear unit oil level through plug A (picture 27)

EVERY 500 HOURS OF WORK

- Check that all bolts and nuts are tightened strongly *

- Change oil in the overgear unit *

EVERY 1000 HOURS OF WORK

Replace the driving belt*

* ATTENTION: this maintenance activity is to be made only at SICMA authorized repair shops.

Picture

20

Picture

21

Loading...

Loading...