What causes shaft end breaks in Siemens 1SE0 Engine?

- LLauren McdonaldSep 13, 2025

Shaft end breaks or stator rotor rubbing in a Siemens Engine can be caused by excessive radial loads due to pulley drives. Check for suitability to resolve this.

What causes shaft end breaks in Siemens 1SE0 Engine?

Shaft end breaks or stator rotor rubbing in a Siemens Engine can be caused by excessive radial loads due to pulley drives. Check for suitability to resolve this.

Defines key safety terms like Danger, Warning, and Caution, and provides general notes.

Outlines requirements for personnel and general safety practices for operating equipment.

Details safe usage in industrial systems and highlights risks of improper handling or maintenance.

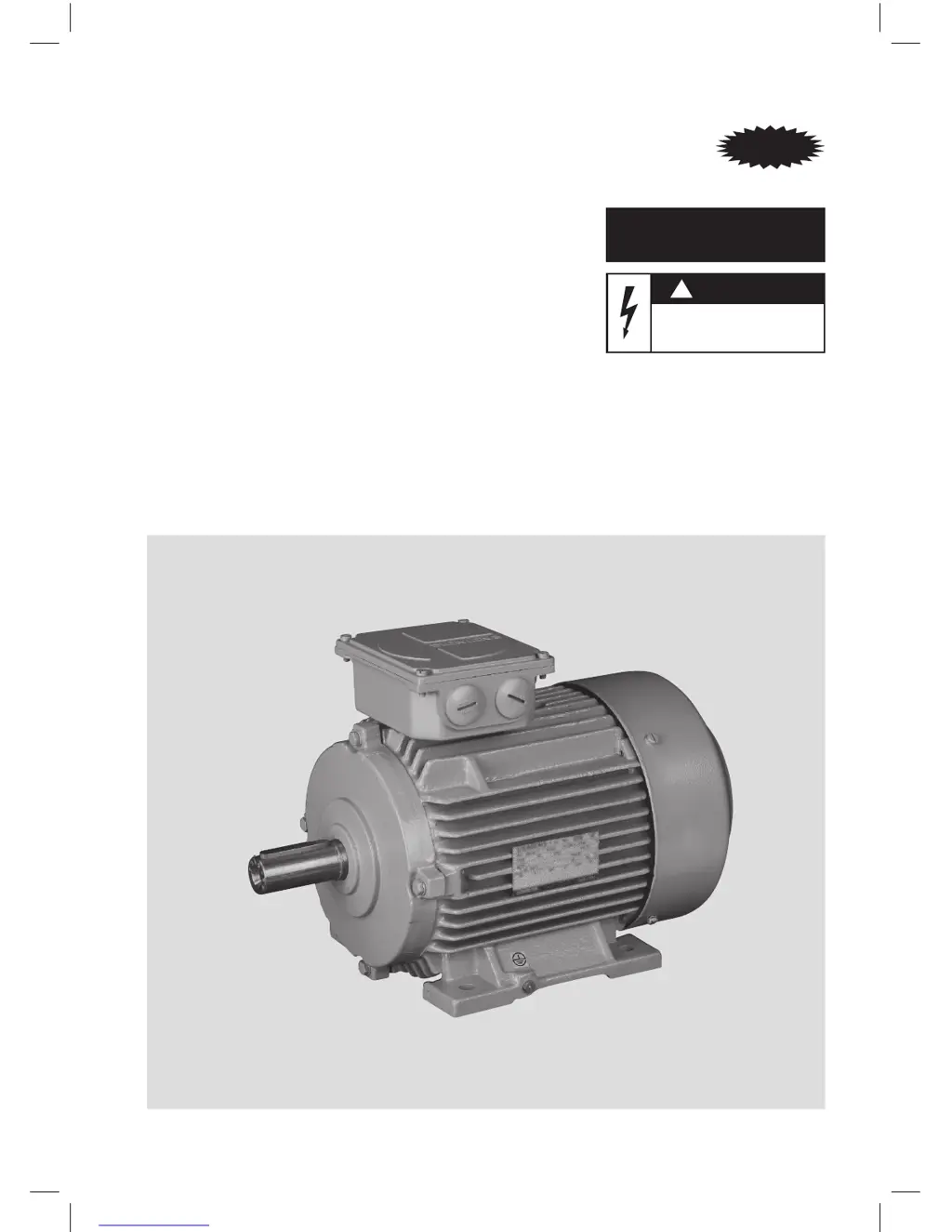

Provides an overview of the Champion series motors, including type and protection standards.

Describes the terminal box conformance to IP55 protection and its standard configuration.

Highlights surface temperature risks and general operational precautions.

Procedures for inspecting, storing, and transporting motors safely.

Specific warnings for lifting and transporting motors using designated eyebolts.

Guidelines for mounting motors horizontally or vertically and ensuring proper alignment.

Steps for installing motors, including shaft preparation and cleaning.

Connecting motors, checking voltage, and wiring configurations (star/delta).

Critical safety warning regarding electrical work on stationary motors.

Correct method for connecting the earthing conductor for safety.

Measuring insulation resistance before initial startup and after storage.

Warning about hazardous voltages present during insulation resistance measurement.

Details on standard bearings, types, clearance, and grease used.

Instructions for fitting transmission elements and rotor balancing.

Safety advice for guarding transmission elements and handling keys.

Procedures and checks before starting the motor.

Final checks and safety precautions before commissioning.

Guidance for motors fitted with brakes or encoders.

Factors affecting EMC emission from motor drives, especially with VFDs.

Requirements for immunity to interference and user responsibilities for detectors.

Potential for increased noise with VFDs due to harmonics.

Guidelines for proper disposal of waste generated during maintenance.

Essential safety rules for performing maintenance on motors, including isolation.

Recommendations for periodic overhauling, cleaning, and general upkeep.

Steps for dismantling motors, including drive elements and fans.

Detailed instructions for removing bearings using appropriate puller tools.

Procedures for reassembling motors, including gaskets, lubrication, and sealing.

Instructions for sealing joints in reassembly for specific protection degrees.

Information required for ordering correct spare parts, including motor type and serial number.

Guidelines for disposing of products at the end of their life, considering environmental impact.

List of standards the motors comply with for design and performance.

Identifies causes and remedies for issues related to hot bearings.

Addresses problems with motor starting, phase issues, and overload.

Covers sluggish start, overheating, vibration, and noise.

Diagnoses issues like voltage problems, misalignments, and rubbing parts.

| Insulation Class | F |

|---|---|

| Cooling Method | IC411 |

| Frequency | 50 Hz |

| Number of Poles | 4 |

| Protection Class | IP55 |

| Ambient Temperature | 40 °C |

Loading...

Loading...