16 / 84

BA 9142 en 02/2015

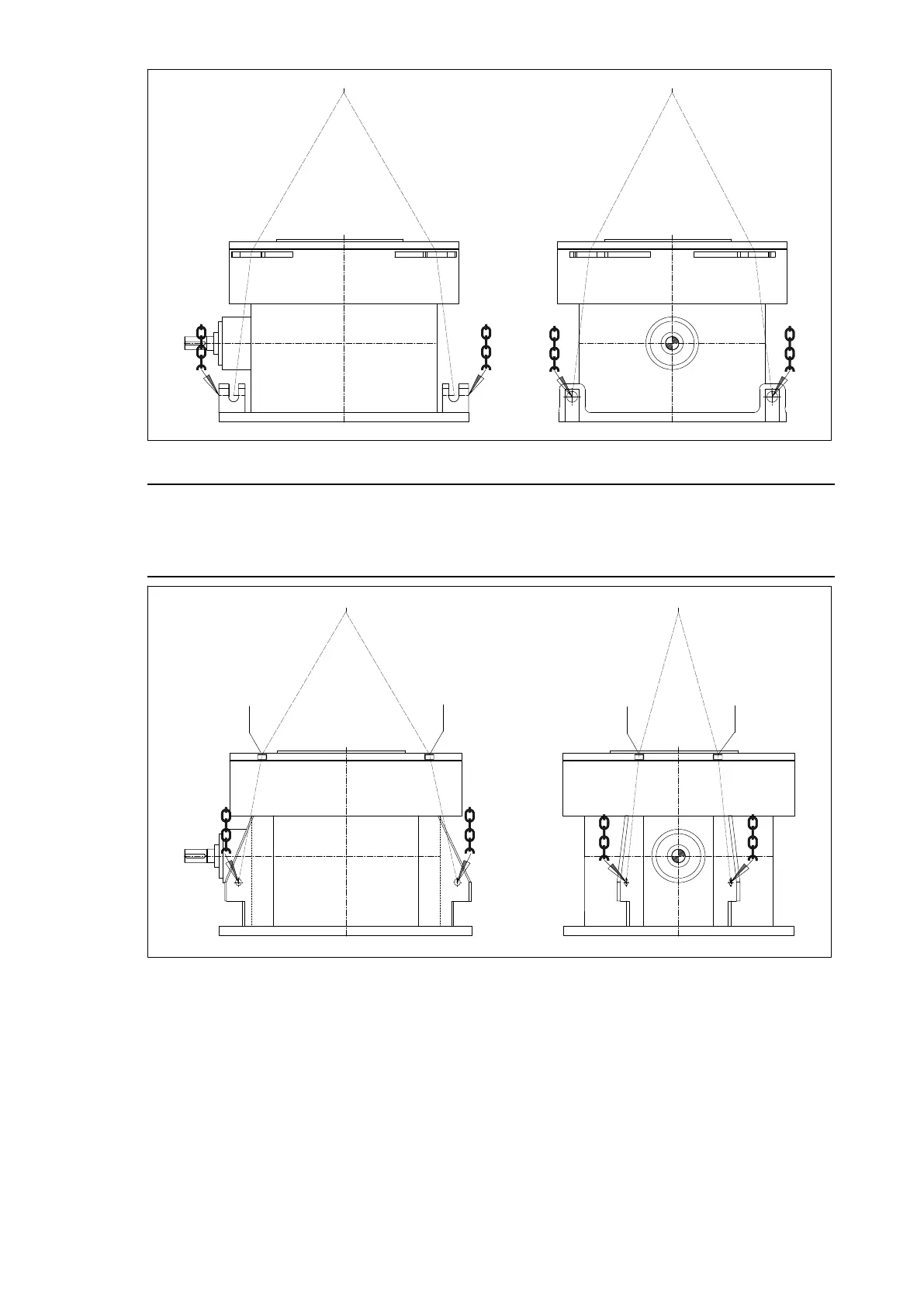

Fig. 3: Attachment points

Note

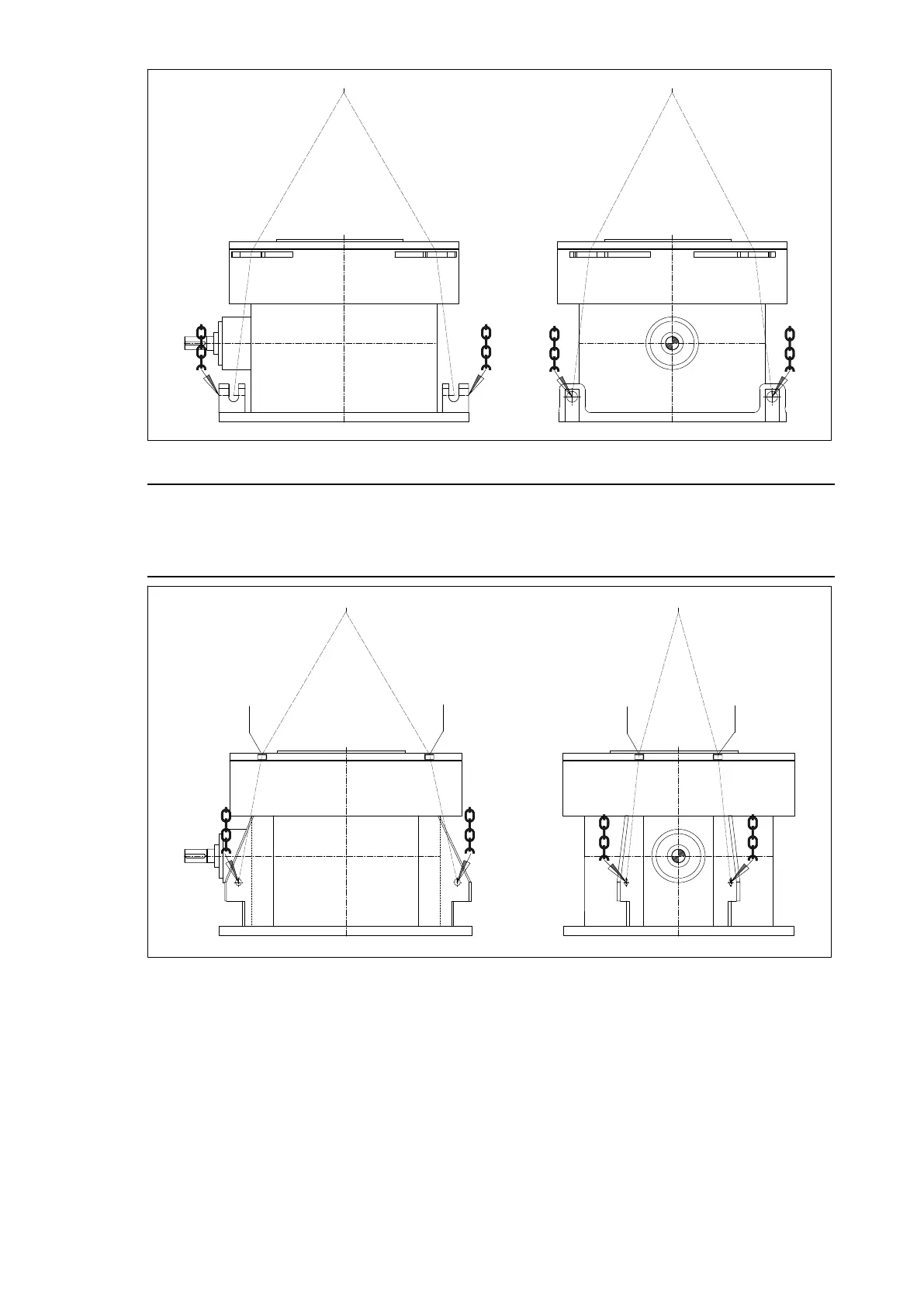

If no transport lobes are provided on the base of the gear unit, the transport lobes that are marked on

the fins have to be used. If no cable pulley is on the gear unit head, wooden blocks have to be used for

protection of the gear unit (see Figure 4).

1

1

1

1

Fig. 4: Alternative attachment points

1 Wooden block

Loading...

Loading...