Technical Instructions QVM62.1 Air Velocity Sensor

Document Number 155-006

October 26, 2006

Page 2 Siemens Industry, Inc.

Operation

(Continued)

A scale with 0.20 in (0.5 cm) grating on the immersion stem and the extension pipe

indicates the immersion depth.

The connecting flange is used to attach and seal the immersion stem on the duct wall.

A plastic housing with removable cover accommodates the transducer. It can be

screwed to a flat surface.

The sensor cable is connected: the sensor and the transducer are a unit.

The measuring ranges are selected by inserting or removing a plug-in jumper.

Protection against false wiring is provided related to own voltages. (Measuring output

U1 is short-circuit proof.) The sensor head connections are not protected against 24

Vac operating voltage.

Components

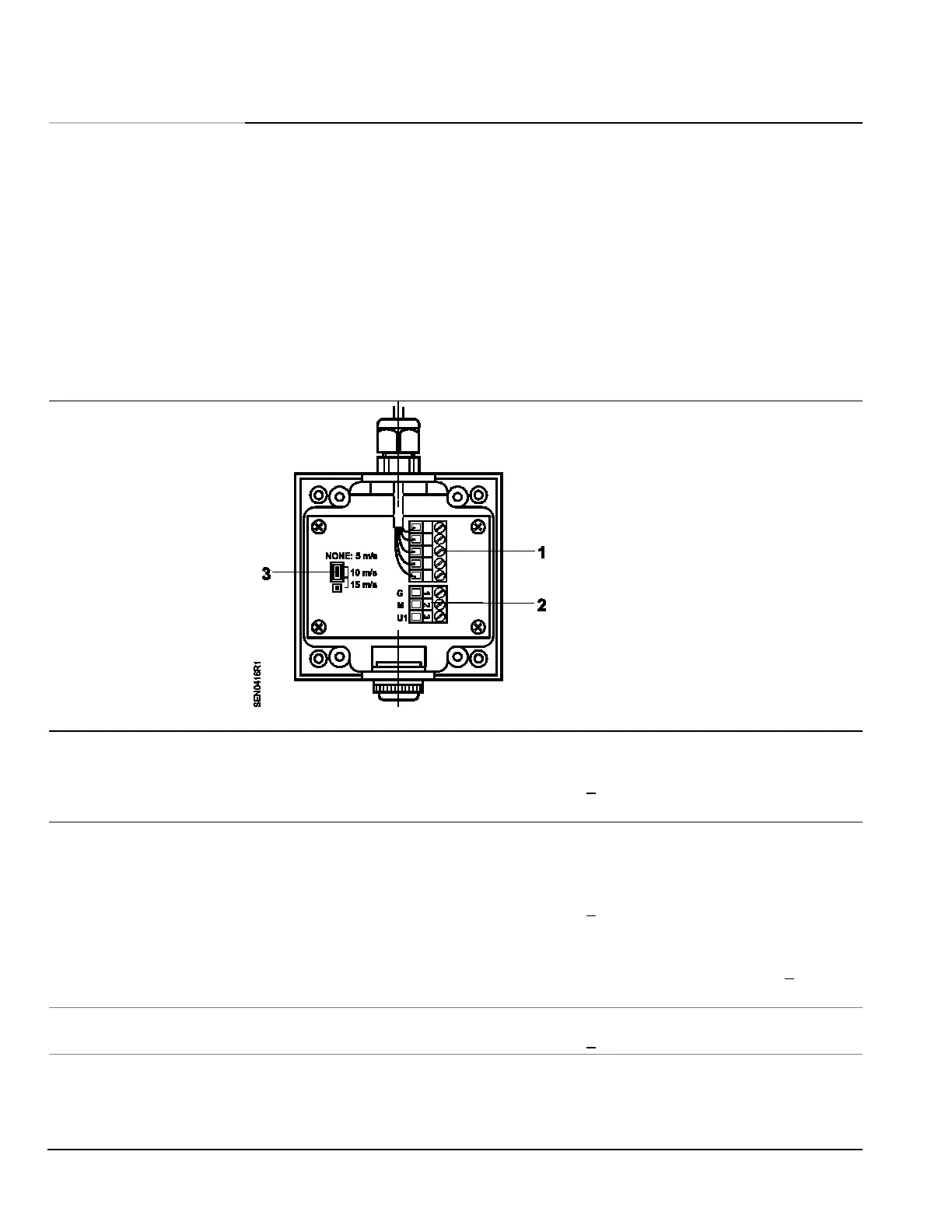

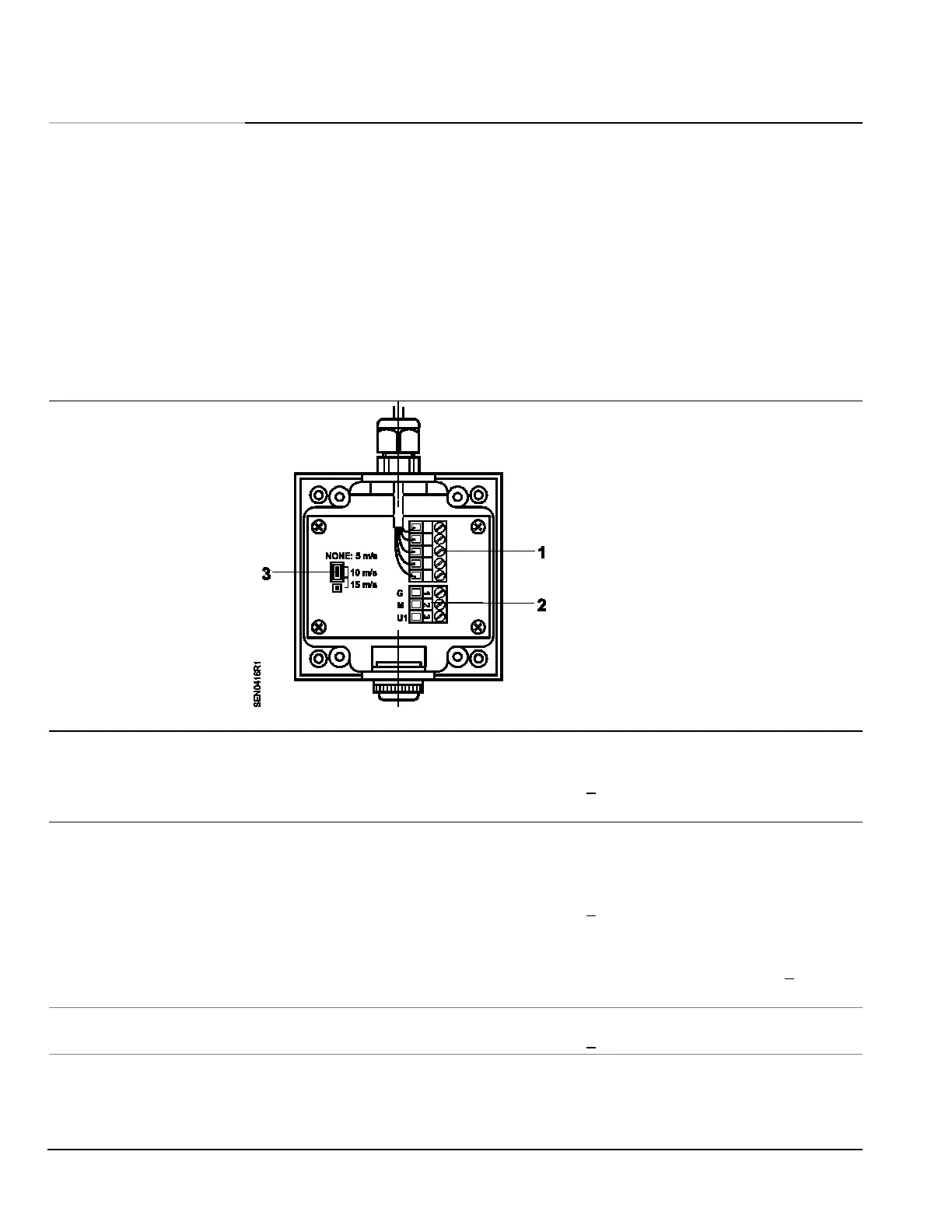

Figure 1. Wiring and Setting Elements.

1 Terminal block for connection to the

immersion stem.

2 Terminal block for connection to the

controller.

3. Plug-in unit for setting the three velocity

ranges.

No plug-in jumper = 0 to 16 ft/s

(0 to 5 m/s)

Plug-in on 1 and 2 = 0 to 32 ft/s

(0 to 10 m/s)

(Factory setting)

Plug-in on 2 and 3 = 0 to 49 ft/s

(0 to 15 m/s)

Specifications

Power supply

Operating voltage 24 Vac +/- 20%

Frequency 50/60 Hz

Power consumption < 5 VA (maximum 200 mA)

Output impedance <20 ohm

Measuring ranges, adjustable 0 to 16 ft/s (0 to 5 m/s)

0 to 33 ft/s (0 to 10 m/s)

(factory setting)

0 to 49 ft/s (0 to 15 m/s)

Measuring accuracy at 68°F (20°C), 45% rh, + 0.7 ft/s (0.2 m/s + 3% of measured

1013 hPa value)

Permissible air velocity 66 ft/s (20 m/s)

Direction dependence < 0.3% of measured value at< + 10°

Time constant t

90

at 10 m/s ca. 4 seconds

Current + 1 mA

Line length Permissible length to controller at:

20 AWG copper cable 164 ft (50 m)

18 AWG copper cable 492 ft (150 m)

16 AWG copper cable 984 ft (300 m)

Line length to the sensor head 3 ft (1 m) (prewired)

Loading...

Loading...