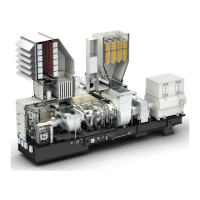

Turbine Package Operators Manual

s

1-1

Chapter 1

Turbine Package System Overview

Engine Core Assembly...................................................................................................................5

General Description...................................................................................................................................5

Air Inlet Casing...........................................................................................................................................5

Compressor Inlet Bearing Housing Assembly........................................................................................5

Compressor Stator Casings......................................................................................................................5

Center Casing and Bearing Housing Assembly......................................................................................6

Combustion System..................................................................................................................................6

Compressor Turbine Outer Casing..........................................................................................................6

Compressor Turbine Nozzle Assembly Stage 1 and Duct .....................................................................6

Turbine Rotor Assemblies ........................................................................................................................6

Power Turbine Outer Casing and Interduct Assembly...........................................................................7

Power Turbine Bearing Housing ..............................................................................................................7

Exhaust Diffuser ........................................................................................................................................7

Auxiliary Gearbox......................................................................................................................................7

Cooling and Sealing Air System...............................................................................................................7

Turbine Instrumentation............................................................................................................................8

Temperature Monitoring........................................................................................................................................... 8

Speed monitoring..................................................................................................................................................... 8

Vibration Monitoring ................................................................................................................................................. 8

Pressure Monitoring................................................................................................................................................. 8

Turbine Core Auxiliary Equipment...........................................................................................................9

Variable Guide Vane (VGV) Actuator....................................................................................................................... 9

Interstage Bleed Valve............................................................................................................................................. 9

P2 Blow-off Valves................................................................................................................................................... 9

Waterwash Nozzles.................................................................................................................................................. 9

Auxiliary Gearbox....................................................................................................................................10

Lubricating Oil System.................................................................................................................11

General Description.................................................................................................................................11

Lubricating Oil Tank ............................................................................................................................................... 11

Lubricating Oil Pumps............................................................................................................................................ 11

Temperature Control Valve.................................................................................................................................... 12

Pressure Control Valve ..........................................................................................................................................12

Lubricating Oil Filters.............................................................................................................................................. 12

Oil Cooler Circuit.................................................................................................................................................... 12

Loading...

Loading...