Do you have a question about the Siemens SGIM-3258C and is the answer not in the manual?

General overview of the switchgear and manual's purpose.

Defines a qualified person and their qualifications.

Explains the meaning of Danger, Warning, and Caution.

Lists critical safety procedures to follow.

Information on obtaining technical assistance from Siemens.

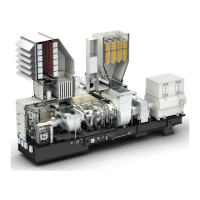

Overview of the switchgear's design and standards.

Outlines the coverage of the manual for different switchgear types.

Describes indoor, shelter-clad, and non-walk-in configurations.

Steps for accepting and inspecting incoming shipments.

Methods for identifying and carefully unpacking equipment.

Protocol for reporting and processing shipping damage.

General methods and precautions for handling switchgear.

Specifics for handling indoor switchgear with cranes and rollers.

Methods for moving when a crane isn't feasible.

Final steps for moving the switchgear assembly.

Instructions for storing indoor, shelter-clad, and non-walk-in switchgear.

Essential steps before installation and foundation specifications.

Specifics for indoor foundations and anchoring.

Specifics for outdoor foundations and anchoring.

Detailed instructions for anchoring indoor units.

Anchoring procedures for single aisle shelter-clad units.

Anchoring procedures for common aisle shelter-clad units.

Anchoring procedures for OGM non-walk-in units.

Guidance on assembling equipment shipped in sections.

Procedure for linking switchgear to a transformer.

Procedures for anchoring, leveling, and assembling indoor units.

Procedures for anchoring and leveling shelter-clad units.

Steps for assembling single aisle shelter-clad units.

Steps for assembling common aisle shelter-clad units.

Assembly steps for units with workspace.

Procedures for adding new units to existing shelter-clad lineups.

Procedures for anchoring, leveling, and assembling non-walk-in units.

Procedures for adding units to existing non-walk-in switchgear.

Steps for assembling single aisle SGM switchgear.

Steps for assembling common aisle SGM switchgear.

Steps for assembling SGM switchgear with workspace.

Details on installing sections and roof components.

Details on bus bar construction and materials.

Procedures for assembling primary bus joints.

Diagrams showing different bus joint connection types.

Explanation of bus insulation systems and safety.

Procedures for installing and securing insulating boots.

Procedures for taping bus joints when boots are not used.

Specific insulation for transformer to switchgear bus joints.

Insulating and terminating primary cables.

Installation and routing of control wiring.

Procedures for making equipment ground connections.

Methods for temporary grounding of circuits.

Overview of VTs and CPTs.

Details on mounting and location of VTs.

Details on CPT mounting and fuse locations.

General safety for operating rollout trays.

Procedures for disconnecting VT rollout trays.

Procedures for connecting VT rollout trays.

Procedures for CPT/fuse rollout tray disconnection.

Procedures for CPT/fuse rollout tray connection.

Description and installation of CTs.

Preparing the cell for breaker installation.

Description of the racking mechanism.

Function of the rating-based blocking plate.

Details on secondary disconnects and cell switches (MOC/TOC).

Grounding contact and shutter mechanisms.

General notes on breaker handling.

Procedure to disconnect control power.

Procedure to ensure springs are discharged.

Steps for removing breakers from indoor/shelter-clad cells.

Visual guide to racking a circuit breaker.

Visual guide to physically removing a circuit breaker.

Steps for removing breakers from outdoor/raised pad cells.

How to use extension rails for breaker removal.

Using a lift truck for breaker handling.

Steps to connect and use the racking crank.

Detailed steps for racking breakers between positions.

Procedure for racking to the CONNECT position.

Procedure for racking to TEST/DISCONNECT positions.

Verifying contact wipe after racking.

Prevents racking closed breakers.

Padlock provisions for preventing racking access.

Ensures breaker is trip-free between TEST/CONNECT.

Prevents removal of breakers with charged springs.

Checklist of items to inspect before energizing.

Procedures and voltages for insulation/dielectric tests.

Steps for initial energization and load connection.

Importance of periodic maintenance and safety.

List of tools for maintenance tasks.

Overview of recommended maintenance and lubrication.

Specifics on lubricating moving parts and contacts.

Methods for cleaning insulation materials safely.

Handling abnormal conditions and protecting surfaces.

Care for relays and instruments.

Inspecting and touching up painted surfaces.

Description of the test device for breaker operation.

Information on test cabinets and lift trucks for breaker handling.

Description of the optional electric racking accessory.

Application and data for surge limiters.

| Operating temperature | -40°C to +75°C |

|---|---|

| Protection class | IP40 |

| MAC Address Table Size | 8K |

| Power input | 12/24/48 VDC redundant dual input |

| Mounting | DIN-Rail |

| Jumbo Frame Support | 9K |

| Input Voltage | 12 - 48 V DC |

| Product type | Managed Industrial Ethernet Switch |

| Weight | 620g |