Electrical Connections

29

Bus Joint Insulation - Taping

Insulation boots are normally provided for repetitive or standard

bus joint conditions. Where boots are not provided, the bus

joints must be carefully taped to the required insulation level

as described below. See Figure 21D, which depicts taped

joints associated with a cable lug mounting arrangement for

multiple cables. Note: When the cables associated with

Figure 21D have been installed, the cable terminations and

the exposed bus must be insulated.

1. Inspect bolted joints to insure they are correctly assem-

bled, bolt heads in proper direction and hardware has

been torqued to proper value. All surfaces must be free of

dust, dirt or other foreign material.

2. Apply a mastic pad over nuts and a second pad over the

bolt heads. Use either small (15-171-988-001: 3.25” x 4.50”

(83mm x 114mm) or large (15-171-988-002: 4.50” x 6.50”

(114mm x 164mm)) size pad most suitable for joint

involved. Remove backing and press adhesive side down and

mold in place covering all sharp projections. Cover hardware

and sharp edges of bus bar if any will be against the tape.

3. Apply half-lapped layers of 4” (102mm) wide tape (15-171-

987-002) or 1” (25mm) wide tape (15-171-987-001) over

the joint. Each layer should overlap the bus bar insulation

by at least 1-1/2” (38mm). Stretching of tape 10% to 15%

in problem areas may help in eliminating voids and wrinkles.

For 5kV class equipment, use two half-lapped layers of tape

over mastic pads. For 8.25kV and 15kV class equipment,

use three half-lapped layers of tape over the mastic pads.

Avoid excessive pressure on the completed bus joint insu-

lation. If bus joints are on standoff insulators, apply tape

per the above procedures except the half-lapped tape

should overlap the insulator by at least 2” (51mm).

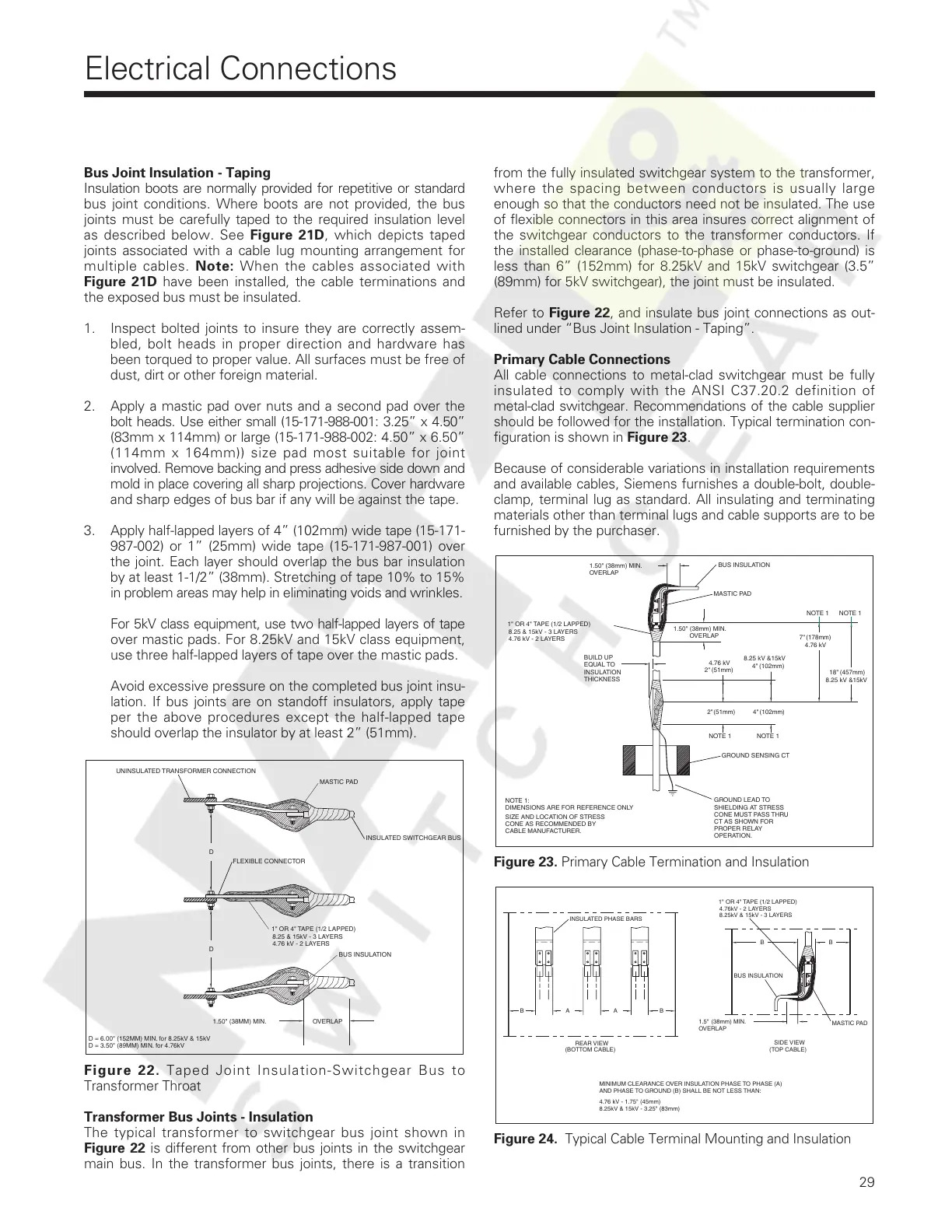

Figure 22. Taped Joint Insulation-Switchgear Bus to

Transformer Throat

Transformer Bus Joints - Insulation

The typical transformer to switchgear bus joint shown in

Figure 22 is different from other bus joints in the switchgear

main bus. In the transformer bus joints, there is a transition

from the fully insulated switchgear system to the transformer,

where the spacing between conductors is usually large

enough so that the conductors need not be insulated. The use

of flexible connectors in this area insures correct alignment of

the switchgear conductors to the transformer conductors. If

the installed clearance (phase-to-phase or phase-to-ground) is

less than 6” (152mm) for 8.25kV and 15kV switchgear (3.5”

(89mm) for 5kV switchgear), the joint must be insulated.

Refer to Figure 22, and insulate bus joint connections as out-

lined under “Bus Joint Insulation - Taping”.

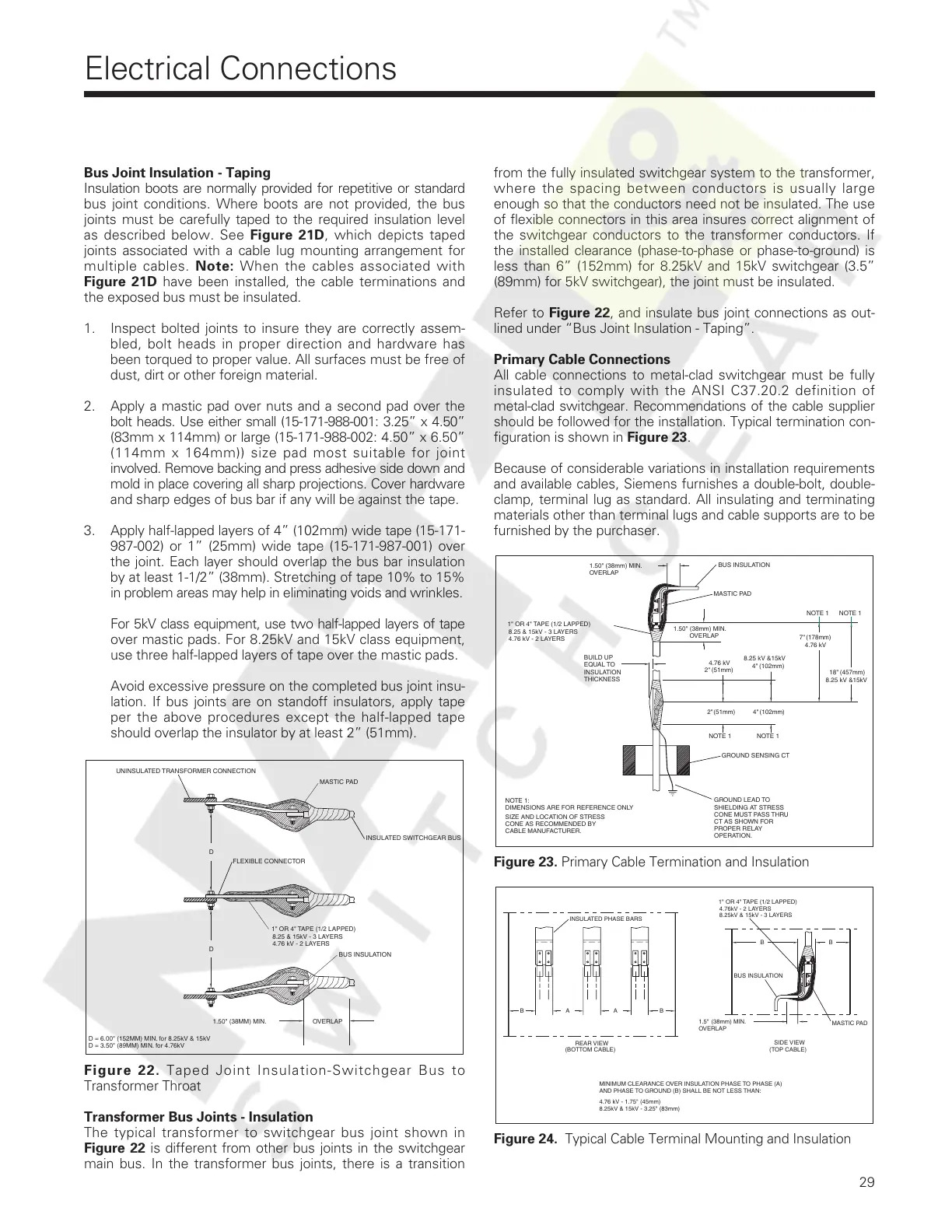

Primary Cable Connections

All cable connections to metal-clad switchgear must be fully

insulated to comply with the ANSI C37.20.2 definition of

metal-clad switchgear. Recommendations of the cable supplier

should be followed for the installation. Typical termination con-

figuration is shown in Figure 23.

Because of considerable variations in installation requirements

and available cables, Siemens furnishes a double-bolt, double-

clamp, terminal lug as standard. All insulating and terminating

materials other than terminal lugs and cable supports are to be

furnished by the purchaser.

Figure 23. Primary Cable Termination and Insulation

Figure 24. Typical Cable Terminal Mounting and Insulation

B

A

A

B

INSULATED PHASE BARS

REAR VIEW

(BOTTOM CABLE)

BB

SIDE VIEW

(TOP CABLE)

MINIMUM CLEARANCE OVER INSULATION PHASE TO PHASE (A)

AND PHASE TO GROUND (B) SHALL BE NOT LESS THAN:

4.76 kV - 1.75" (45mm)

8.25kV & 15kV - 3.25" (83mm)

BUS INSULATION

MASTIC PAD

1" OR 4" TAPE (1/2 LAPPED)

4.76kV - 2 LAYERS

1.5"

(38mm) MIN.

8.25kV & 15kV - 3 LAYERS

OVERLAP

GROUND SENSING CT

GROUND LEAD TO

SHIELDING AT STRESS

CONE MUST PASS THRU

CT AS SHOWN FOR

PROPER RELAY

OPERATION.

BUILD UP

EQUAL TO

INSULATION

THICKNESS

2"

2"

18"

MASTIC PAD

1" OR 4" TAPE (1/2 LAPPED)

8.25 & 15kV - 3 LAYERS

BUS INSULATION

1.50" (38mm) MIN.

OVERLAP

OVERLAP

1.50" (38mm) MIN.

4.76 kV - 2 LAYERS

4"

4"

(457mm)

8.25 kV &15kV

7"

(178mm)

4.76 kV

4.76 kV

8.25 kV &15kV

(102mm)(51mm)

(51mm)

(102mm)

NOTE 1 NOTE 1

NOTE 1 NOTE 1

SIZE AND LOCATION OF STRESS

CONE AS RECOMMENDED BY

CABLE MANUFACTURER.

NOTE 1:

DIMENSIONS ARE FOR REFERENCE ONLY

UNINSULATED TRANSFORMER CONNECTION

INSULATED SWITCHGEAR BUS

FLEXIBLE CONNECTOR

MASTIC PAD

BUS INSULATION

D

D = 6.00" (152MM) MIN. for 8.25kV & 15kV

8.25 & 15kV - 3 LAYERS

1.50" (38MM) MIN.

OVERLAP

D

1" OR 4" TAPE (1/2 LAPPED)

4.76 kV - 2 LAYERS

D = 3.50" (89MM) MIN. for 4.76kV

Courtesy of NationalSwitchgear.com

Loading...

Loading...