7.B.1. On copper-copper bus joints, place a flat washer against

the bar with a lockwasher between the flat washer and

the nut.

7.B.2. On copper-aluminum or aluminum-aluminum bus joints,

a “Belleville” spring washer is placed under the nut, with

the concave side of the spring washer against the bus

bar.

7.C. Spacers are required at certain bus joints to insure the

cross sectional area of the joint. The conditions where

these spacers are required vary with the type of bus joint.

Refer to Figure 18.

8. Torque the .50” SAE Grade No. 5 cap screws to 50-75 lb-ft.

(68-102 Nm) torque. (If special hardware is required by an

order, other torque values will be supplied with field

assembly drawings.)

9. Install insulation boots or tape joints where required per

instructions in following sections.

10. Connect ground bus. See Figure 28. Insert bar in side

wall opening to overlap the ground bus in adjacent cubicles.

11. Torque the 0.38” SAE Grade 5 cap screw used in the

ground bus to 25-40 lb-ft. (34 to 54 Nm).

Electrical Connections

24

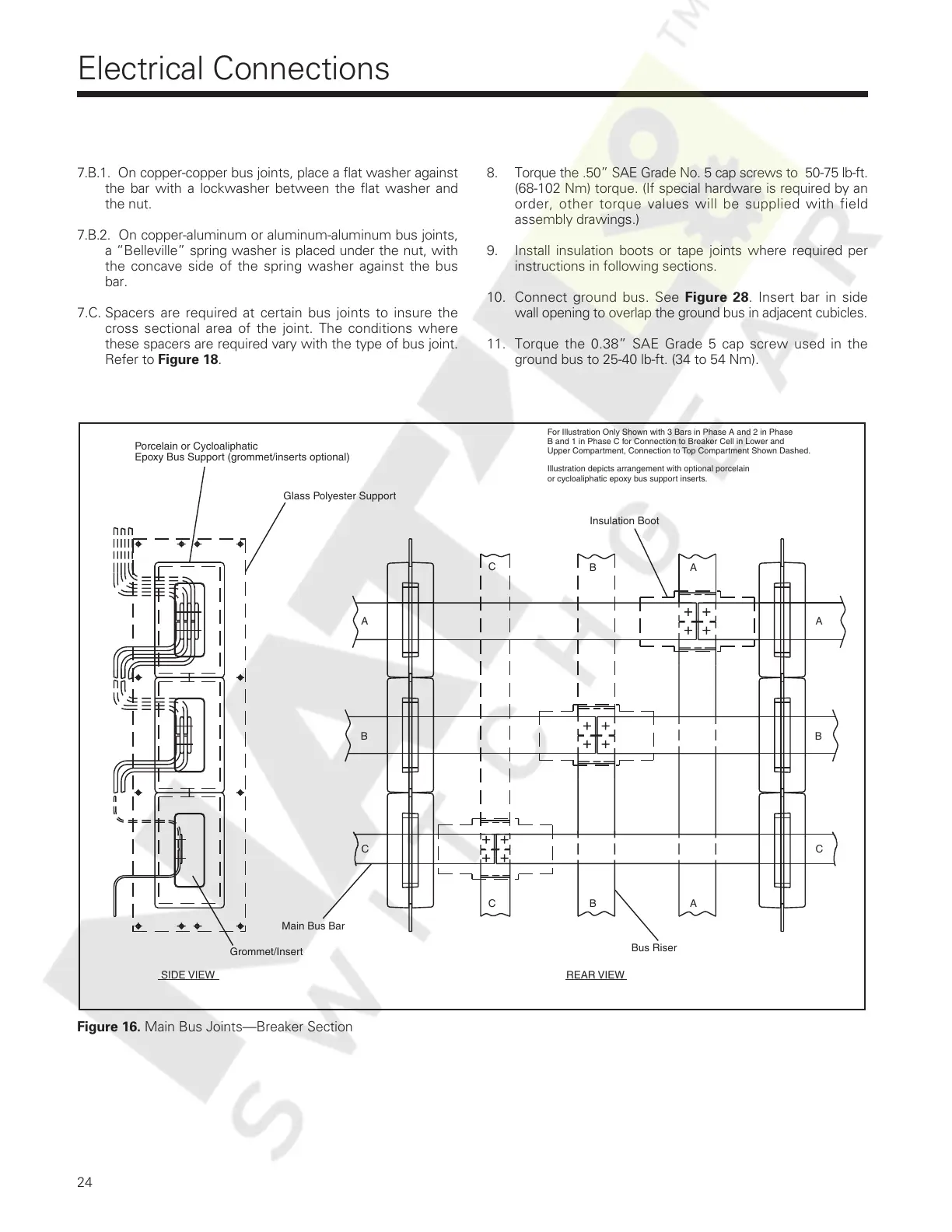

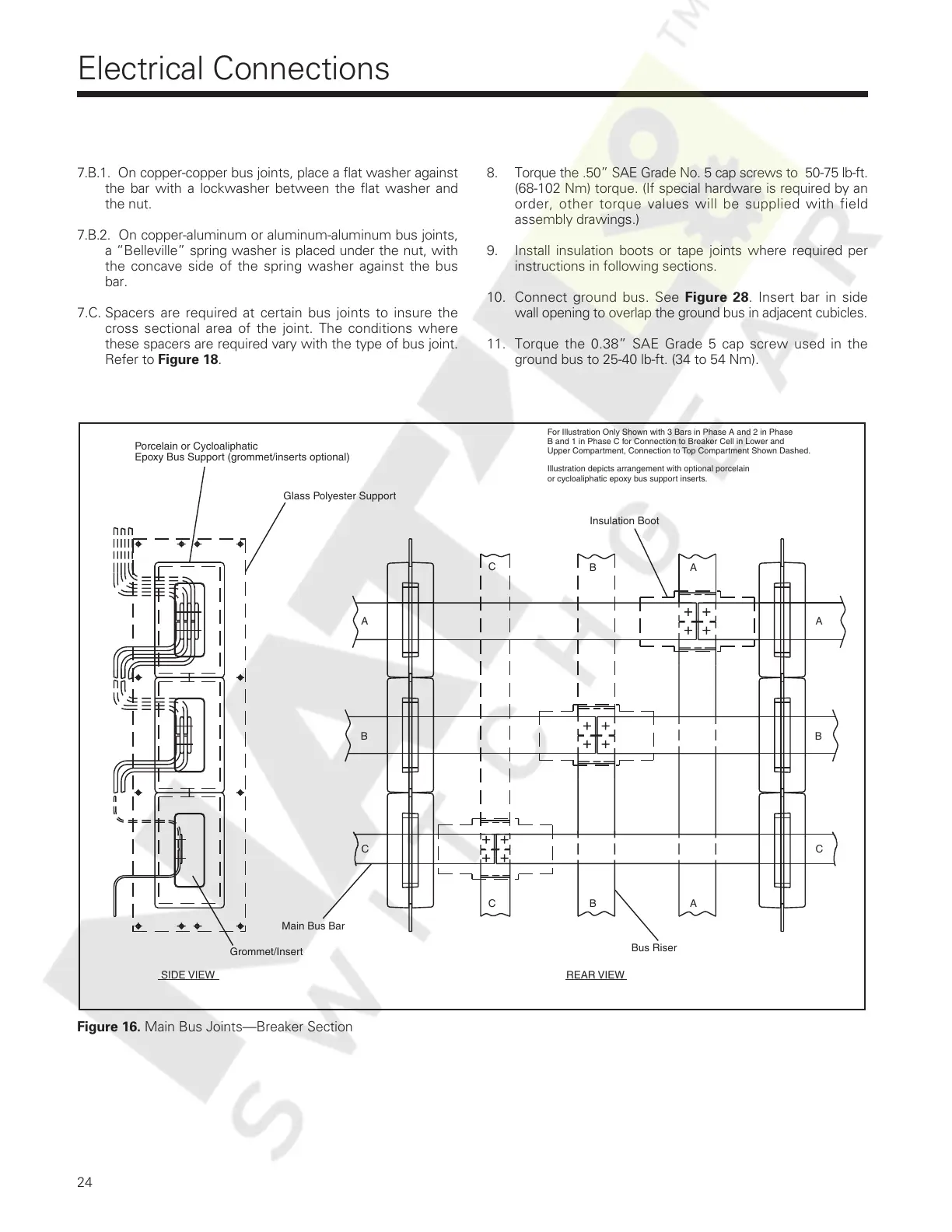

Figure 16. Main Bus Joints—Breaker Section

Insulation Boot

Bus Riser

REAR VIEW

Main Bus Bar

SIDE VIEW

A

B

C

For Illustration Only Shown with 3 Bars in Phase A and 2 in Phase

B and 1 in Phase C for Connection to Breaker Cell in Lower and

A

B

C

Upper Compartment, Connection to Top Compartment Shown Dashed.

A

B

C

Glass Polyester Support

Porcelain or Cycloaliphatic

Epoxy Bus Support (grommet/inserts optional)

Grommet/Insert

A

B

C

or cycloaliphatic epoxy bus support inserts.

Illustration depicts arrangement with optional porcelain

Courtesy of NationalSwitchgear.com

Loading...

Loading...