66 SSeettuupp aanndd OOppeerraattiioonn

6.1 Setup Controls

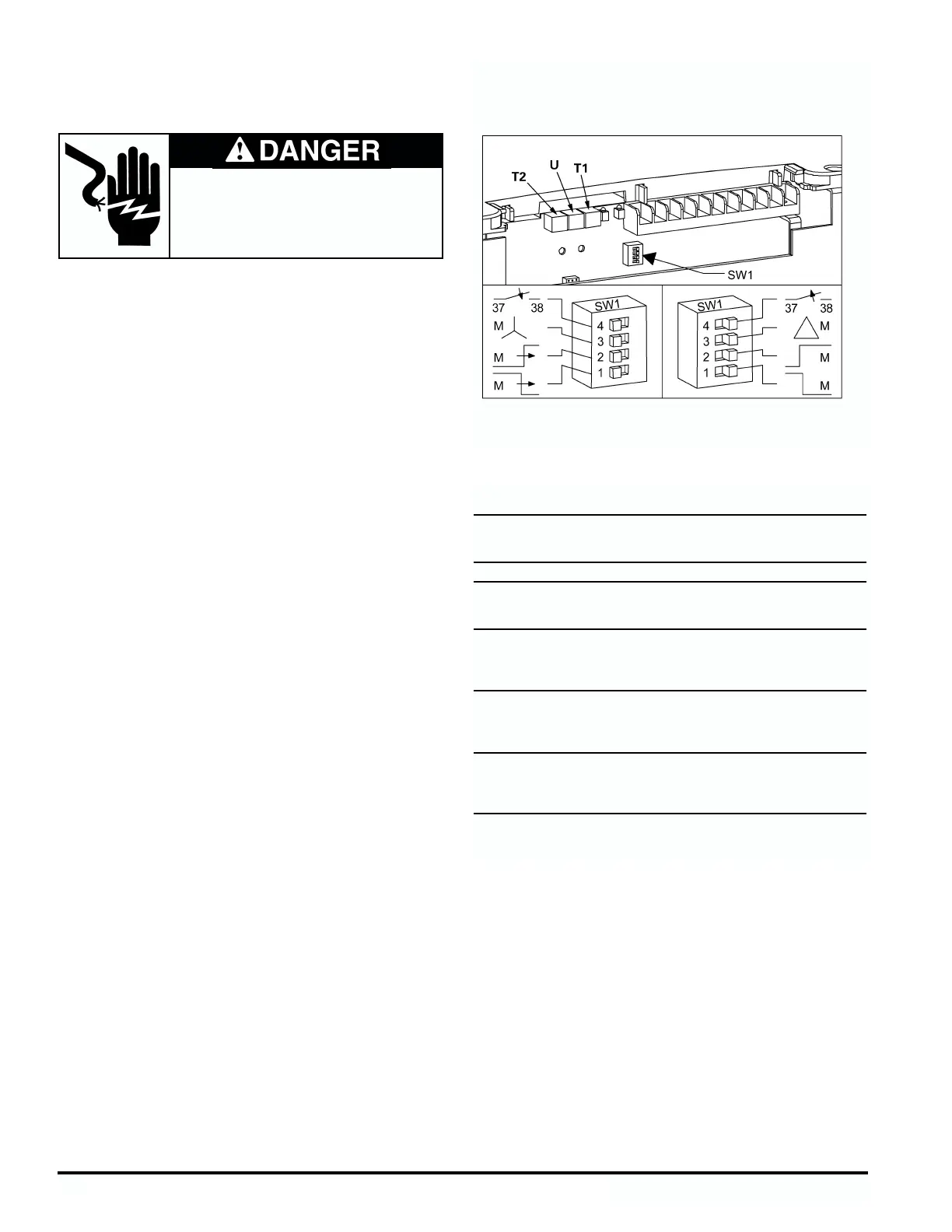

The setup controls are at the right side of the controller and are

accessible without removing the cover. Figure 20 shows the

controls: three potentiometers, T1, U, and T2; and DIP switch

SW1. Values for the potentiometer settings are listed in Table 6.

Use a small screwdriver to change the potentiometer setting,

rotating clockwise to increase and counterclockwise to

decrease.

Note: The controls are set at the factory for a typical starter.

Please verify the application for proper settings.

T1 - Start Time. This 16-position potentiometer sets the accel-

eration ramp time up to 60 seconds maximum. This setting

determines the time interval for the voltage to increase from the

initial setting (U) to line voltage. The factory settings is 8.

U - Initial Voltage. This 16-position potentiometer sets the ini-

tial voltage at a percentage of line voltage: 30% to 80%. The ini-

tial setting should be the level that causes the motor shaft to

turn as soon as the run signal is given. The factory setting is

8.

T2 - Stop Time. This 16-position potentiometer sets the decel-

eration ramp time up to 60 seconds maximum. This setting

determines the time interval for the voltage to decrease from

line voltage to 80% of the initial setting (U).The “0” dial position

allows the motor to coast to a stop. The factory setting is 0.

SW1 - DIP Switch. This switch has four sections which provide

setting the controller software to correspond to the application.

Each switch section is positioned by sliding it to the right or left

as viewed in figure 20 (up or down when the controller is

mounted vertically). On the wiring diagrams in section 5, the

position of each switch section is indicated by an arrow pointing

to either the right or left.

1. SW1-1: This switch provides a turn off delay signal setting

(left position). The off delay allows a bypass contactor to de-

energize 1.5 seconds before the controller RUN coil de-ener-

gizes. This delay eliminates damage to the SCRs caused by

voltage transients produced when the bypass contactor

interrupts motor current.

The right position of switch SW1-1 provides no delay. When

the stop device is actuated, the RUN coil de-energizes

immediately.

2. SW1-2: This switch provides a turn on delay signal setting

(left position). The on delay allows an isolation contactor to

energize first, at zero current, followed by the controller RUN

coil 1.5 seconds later. The delay maximizes contact life on

the isolation contactor.The right position of switch SW1-2

provides no delay. When the start device is actuated, the

RUN coil energizes immediately.

3. SW1-3: This switch directs the controller software to oper-

ate the SCRs for either a Wye motor - In Line wiring (left

position) or a Star/Delta motor - Inside Delta wiring (right

position).

4. SW1-4: This switch sets the fault contact, which is a nor-

mally open contact,to respond to a fault by either closing

(arrow down position, switch to the left) or opening (arrow

up position, switch to the right).

Siemens Energy & Automation, Inc.

28

Hazardous voltage.

Will cause death or serious injury.

To avoid electrical shock or burn, turn off

main and control voltages before performing

installation or maintenance.

Figure 20 - Setup Controls

Table 6 - Potentiometer Setting Values

Ramp Time

Dial Initial Voltage U T1, T2

Setting (% Full Voltage) (Seconds)

030 0.5

133 1.0

236 2.0

340 4.0

443 6.0

546 8.0

650 10

753 12

856 15

960 20

A63 25

B66 30

C70 35

D73 40

E76 50

F80 60

Factory Settings T1=8 (15 sec)

T2=0 (.5 sec)

V=8 (56%)

Loading...

Loading...