Operating and Programming — Milling Page 102 808D

ISO

Mode

s

Basic Theory

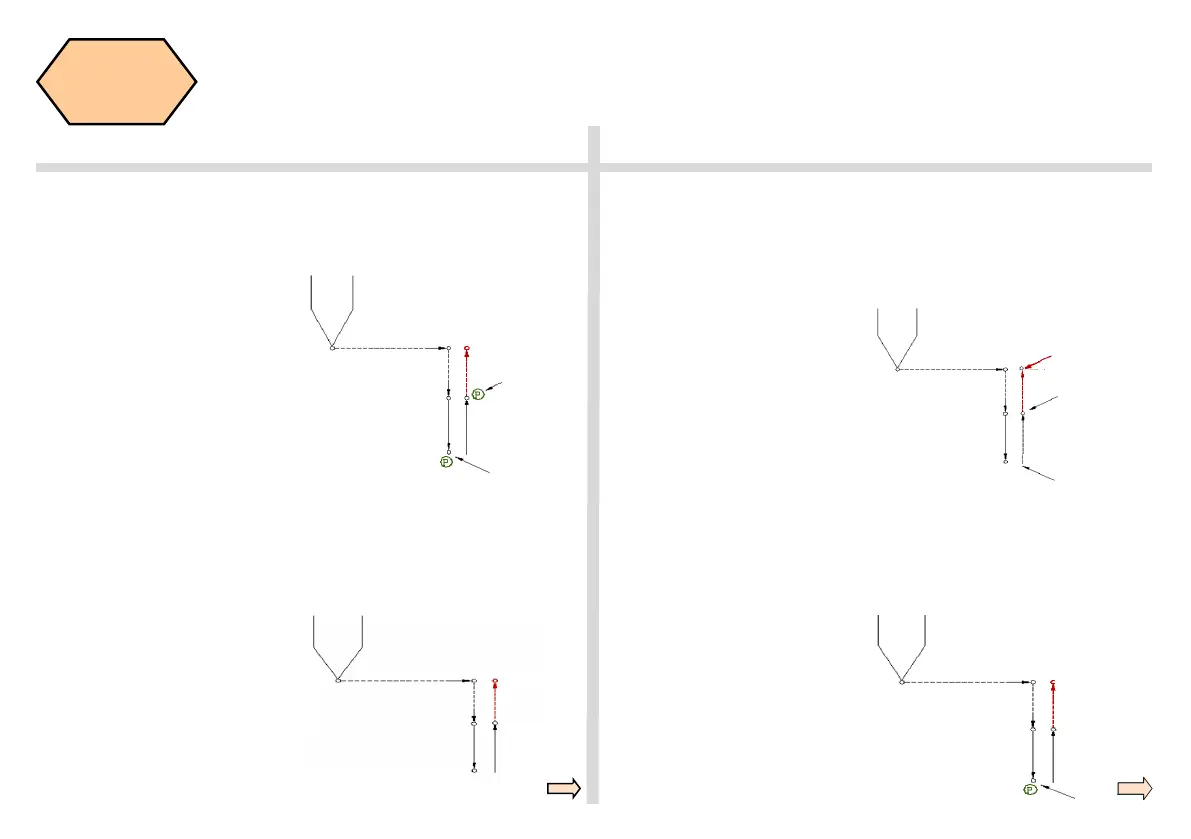

G84 execution operation graphic:

With command G99 without operation in red line

With command G98 with operation in red line

G84 Tapping cycle

Common programming structures:

G84 X—Y—Z—R—P—F—K

Motion process:

① Drilling motion (-Z) → cutting feed

② Motion at the bottom of the hole →

spindle rotation in negative direction

③ Retraction motion (+Z) → cutting feed

G85 boring cycle

Common programming structures:

G85 X—Y—Z—R—F—K

Motion process:

① Drilling motion (-Z) → cutting feed

② Motion at the bottom of the hole →

none

③ Retraction motion (+Z) → cutting feed

G85 execution operation graphic:

With command G99 without operation in red line

With command G98 with operation in red line

Except that the spindle is not rotating at the

bottom of the hole, G85 is same as G84

G86 execution operation graphic:

With command G99 without operation in red line

With command G98 with operation in red line

Except for the stop at the bottom of the hole,

G86 is same as G81

G86 boring cycle

Common programming structures:

G86 X—Y—Z—R—F—K

Motion process:

① Drilling motion (-Z) → cutting feed

② Motion at the bottom of the hole →

spindle stop

③ Retraction motion (+Z) → fast feed

G89 boring cycle

Common programming structures:

G89 X—Y—Z—R—P—F—L

Motion process:

① Drilling motion (-Z) → cutting feed

② Motion at the bottom of the hole →

pause

③ Retraction motion (+Z) → cutting

feed

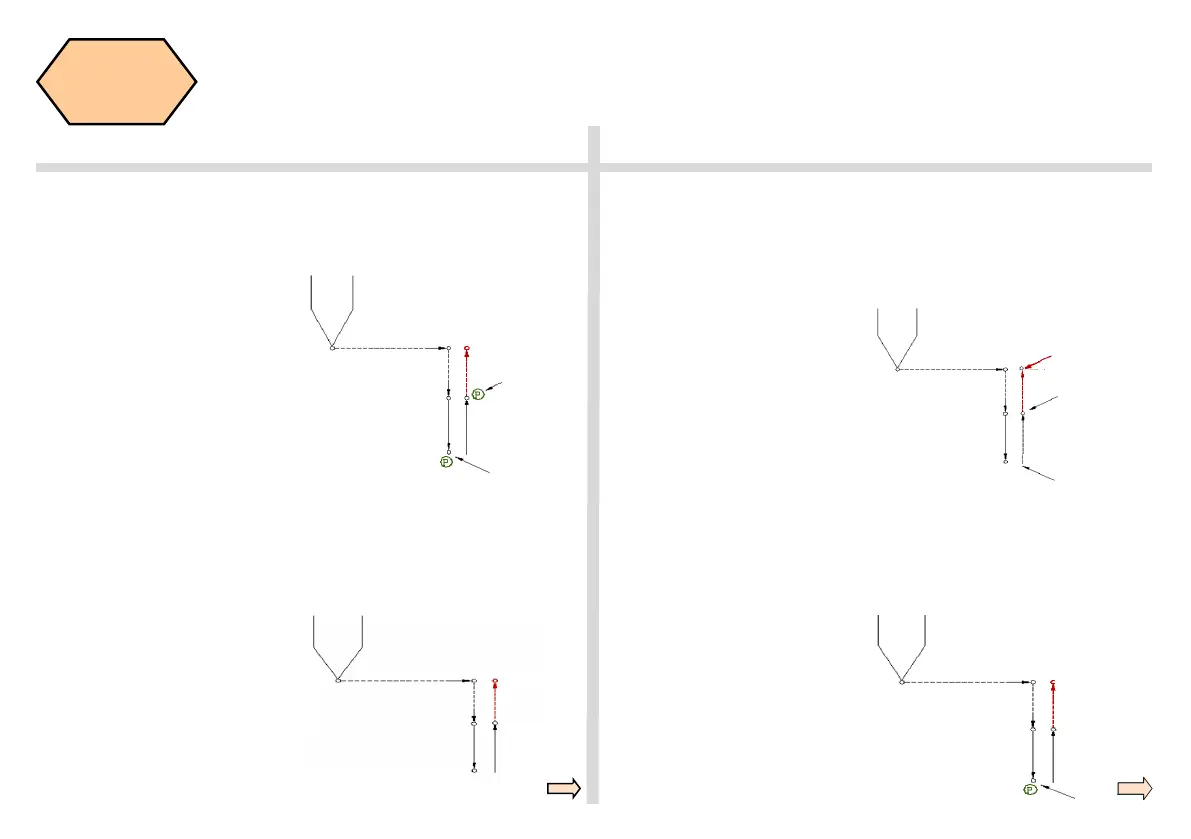

G89 execution operation graphic:

With command G99 without operation in red line

With command G98 with operation in red line

Except that the spindle stops at the bottom of the

hole, G89 is same as G85

Origin

spindle CW

after pause

R Point

Z Point

spindle CCW

after pause

Origin

R Point

Z Point

Origin

R Point

Z Point

Pause

spindle CW

after pause

Origin

spindle CW

after pause

R Point

Z Point

spindle stop

after pause

Loading...

Loading...