Operating and Programming — Milling Page 34 808D

Create Part

Program

Part 1

s

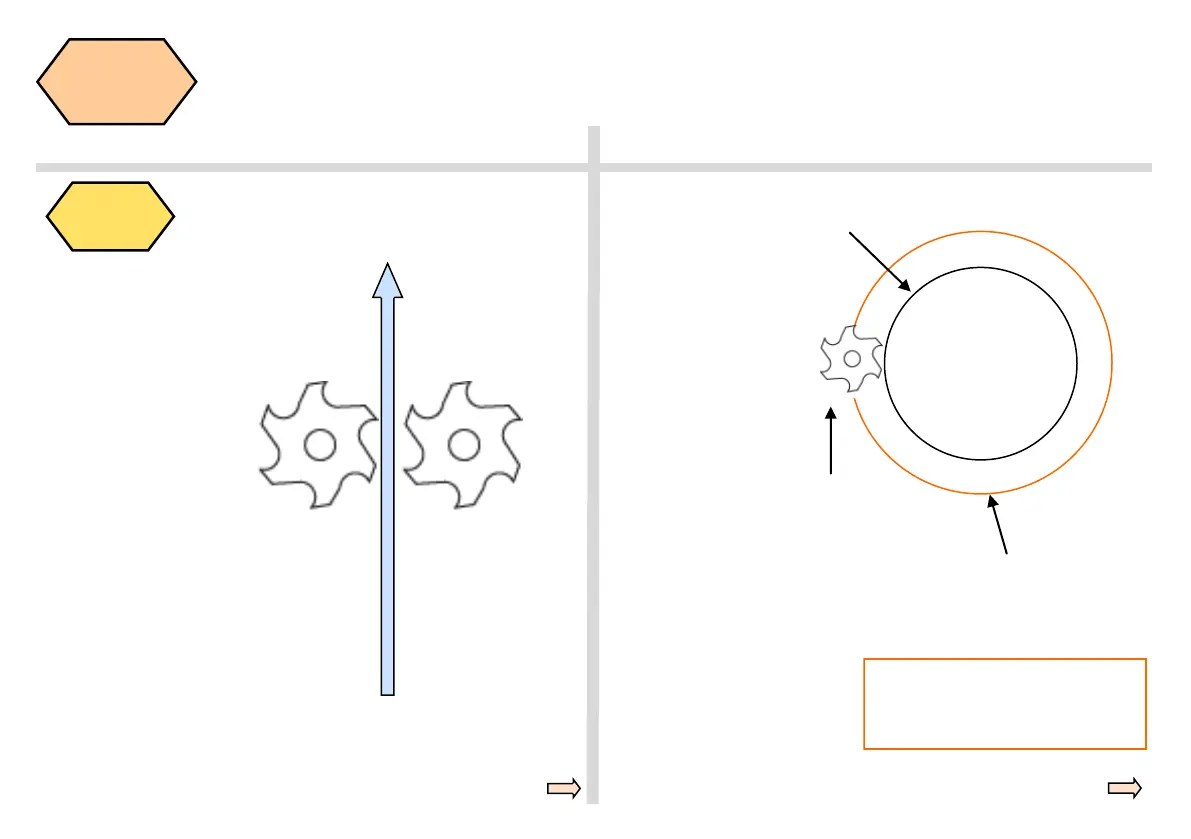

Basic Theory

Behavior at

corners

Activation/

deactivation of the

tool radius compen-

sation when working

on the part contour.

G41 / G42 and G40

With G41/G42,

the tool radius com-

pensation will be

done in the direction

of travel.

G41:Compensation

to left

G42:Compensation

to right

G40:Compensation

of the radius can be

deactivated

Arrow indicates the

direction of tool motion

along the contour.

G41 → direction

along the tool mo-

tion, tool is always

on the left of the

contour.

G42 → direction

along the tool mo-

tion, tool is always

on the right of the

contour.

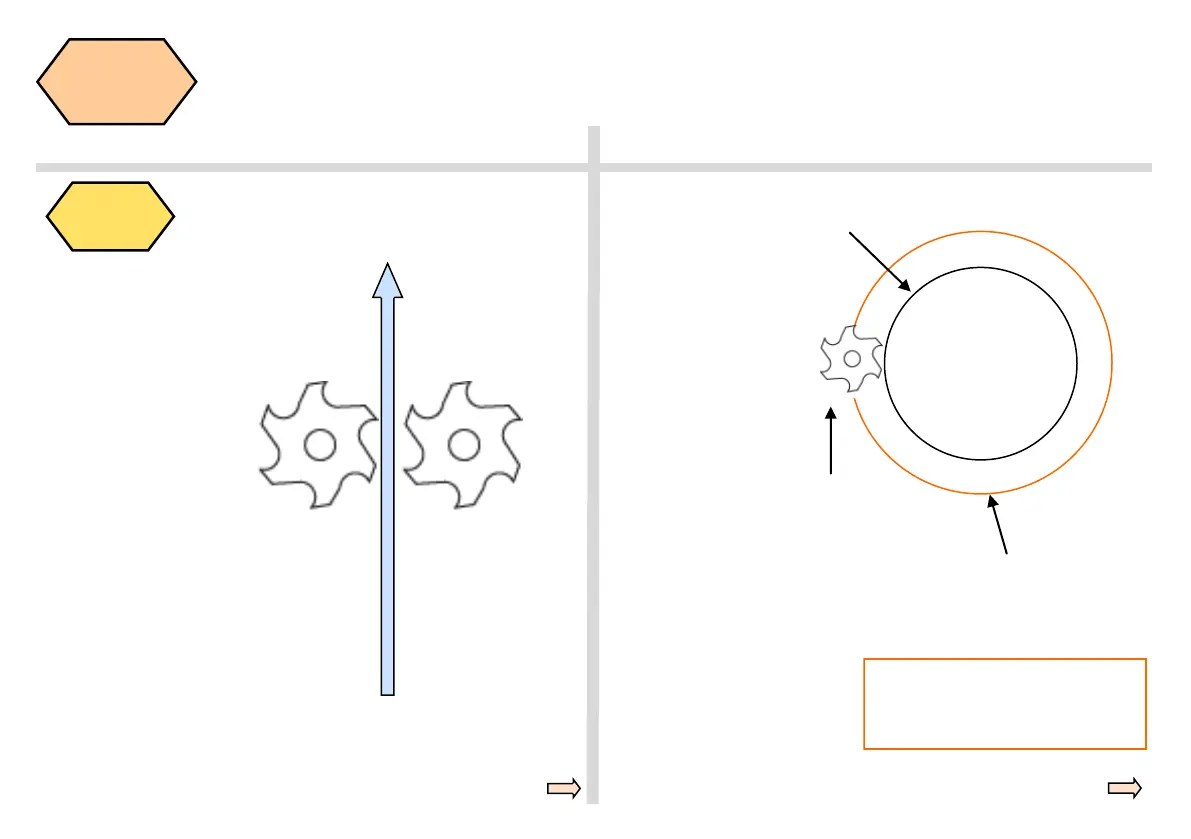

Contour feedrate with

CFC

Direction for com-

pensation, left of

contour will be

G41

Feedrate calcu-

lated when using

tool center, inside

or outside of the

contour

The result of the two commands will

be such that the cutter goes very fast

around a corner or slow on the con-

tour.

When traversing circular

contours with cutter radius

compensation, it should be

decided whether the feed

rate should be calculated

along the contour of the

workpiece or along the path

defined by the center point

of the cutting tool.

When using a contour with

a feed rate defined by the

CFC code, the feed rate will

be constant at the contour,

but in some cases, it may

cause increases in the feed

rate of the tool.

This increase could dam-

age the tool if excessive

material is encountered at

the contour; this function is

normal for finish cutting of

contours.

The CFTCP command

ensures a constant feed

rate, however a constant

feed rate may not be en-

sured at the contour, which

may cause deviations in

surface finish.

Loading...

Loading...