808D Page 45 Operating and Programming — Milling

Create Part

Program

Part 2

s

Basic Theory

→

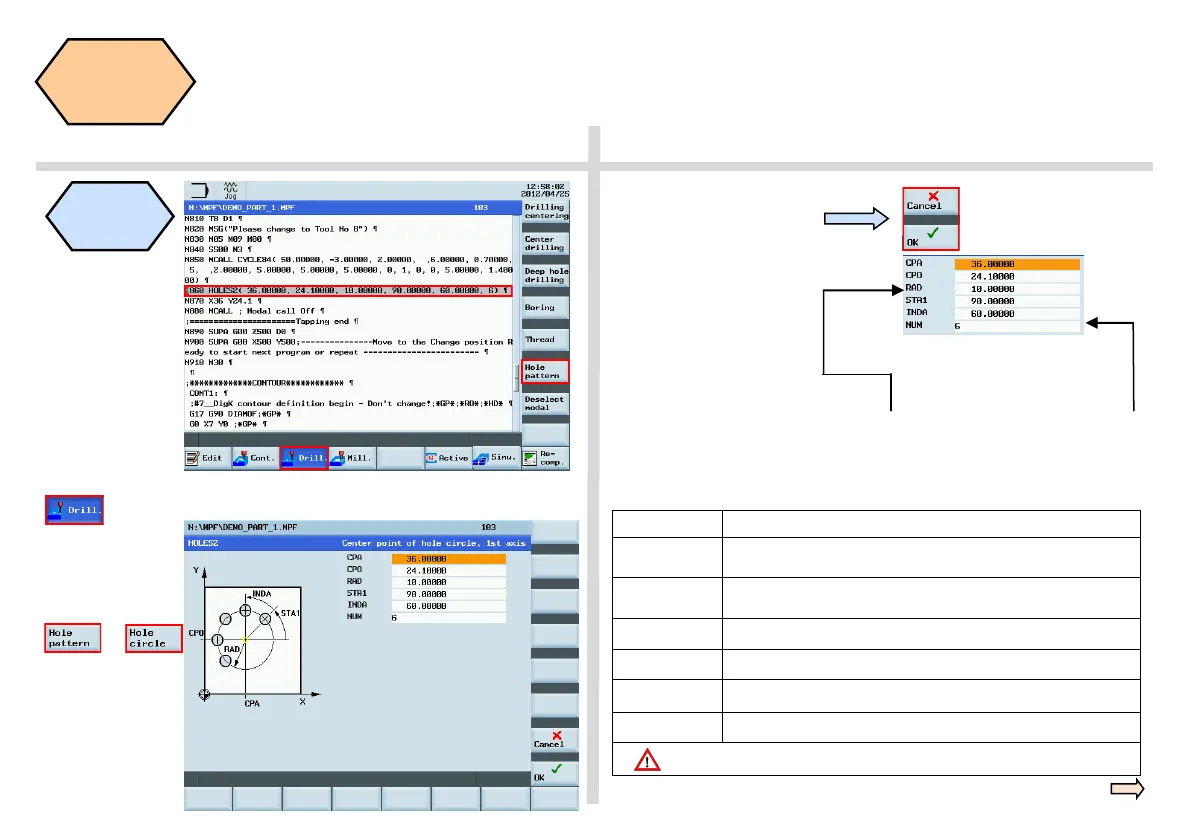

The easiest way to

drill a series of

holes is to use the

pre-defined “Hole

pattern” cycles.

The cycles can be

found and parame-

terized via the

“Drill.” SK.

The relevant cycle

can now be found

using the vertical

SKs on the right.

Select

“Hole pattern” using

the vertical

SKs ,and then se-

lect “Hole circle”,

and parameterize

the cycle according

to requirement.

Hole

positioning

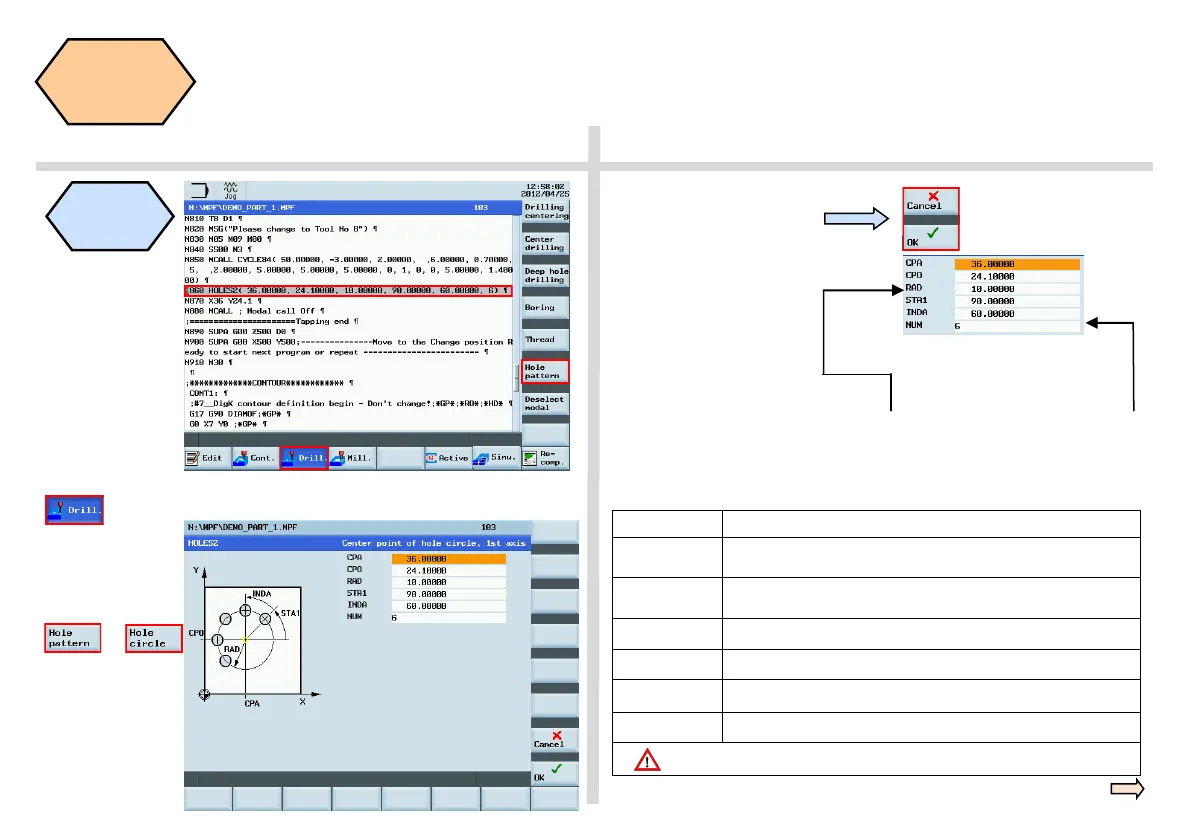

N325 MCALL CYCLE82( 50.00000, -3.00000, 2.00000, -5.00000, 0.00000,

0.20000)

N330 HOLES2( 36.00000, 24.10000, 10.00000, 90.00000, 60.00000, 6)

N335 X36 Y24.1

N340 MCALL ; Modal Call OFF

With the “OK” SK, the val-

ues and cycle call will be

transferred to the part pro-

gram as shown below.

This will drill holes at the

positions defined from

within the cycle.

Parameters Meanings

CPA=36 Center of hole circle horizontal coordinate is 36 (absolute value)

CPO=24.1 Center of hole circle horizontal coordinate is 24.1 (absolute value)

RAD=10 Circle radius is 10 mm

STA1=90 Angle between the circle and horizontal coordinate is 90º

INDA=60 Angle between the circles is 60º

NUM=6 Drill 6 holes on circle

The cycle is used together with the drilling fixed cycle to decrease the hole clearance

Loading...

Loading...