Operating and Programming — Milling Page 80 808D

Additional

Information

Part 2

s

Basic Theory

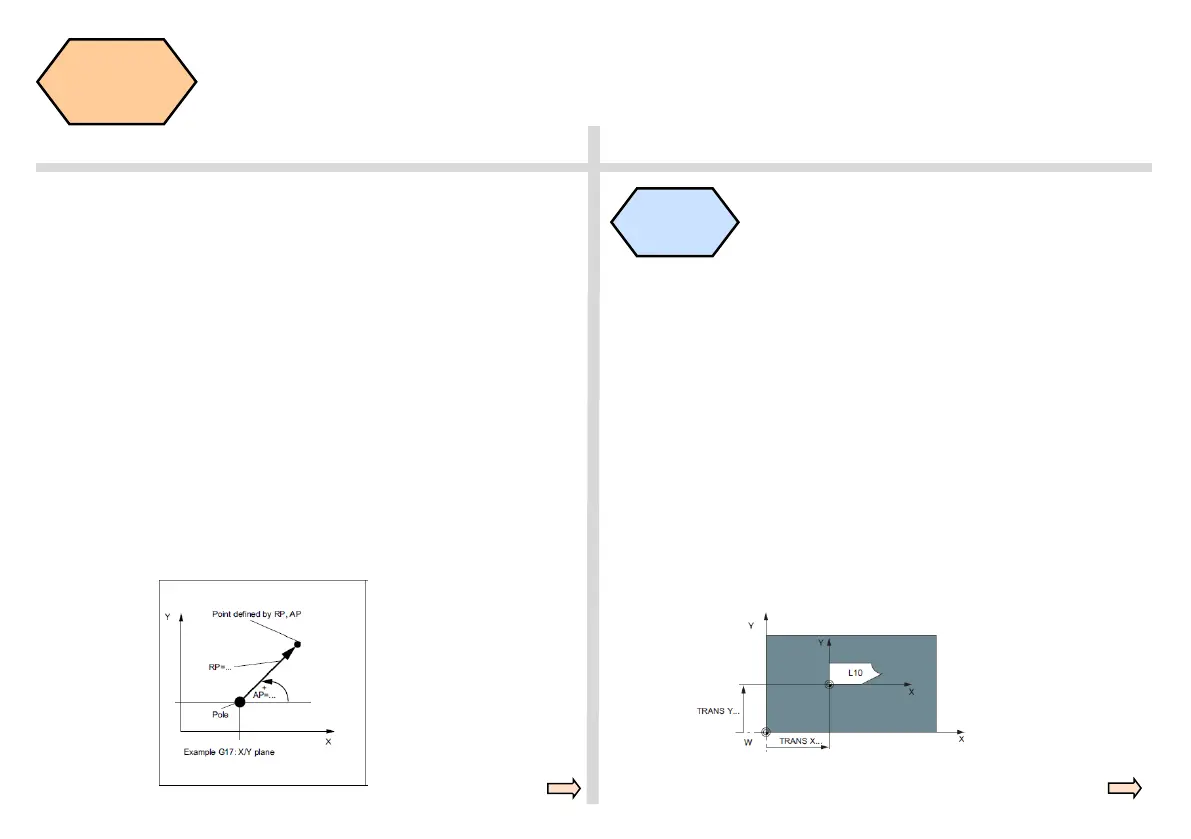

The programmable workpiece offsets TRANS and ATRANS can be used

in the following cases:

● For recurring shapes/arrangements in various positions on the work-

piece

● When selecting a new reference point for dimensioning

This results in the current workpiece coordinate system.

TRANS X...Y... Z... ; programmable offset(absolute)

ATRANS X...Y... Z... ; programmable offset, additive to existing offset

(incremental)

TRANS ; without values, clears old commands for offset

Programming example

N20 TRANS X20.0 Y15.0 programmable offset

L10 subprogram call

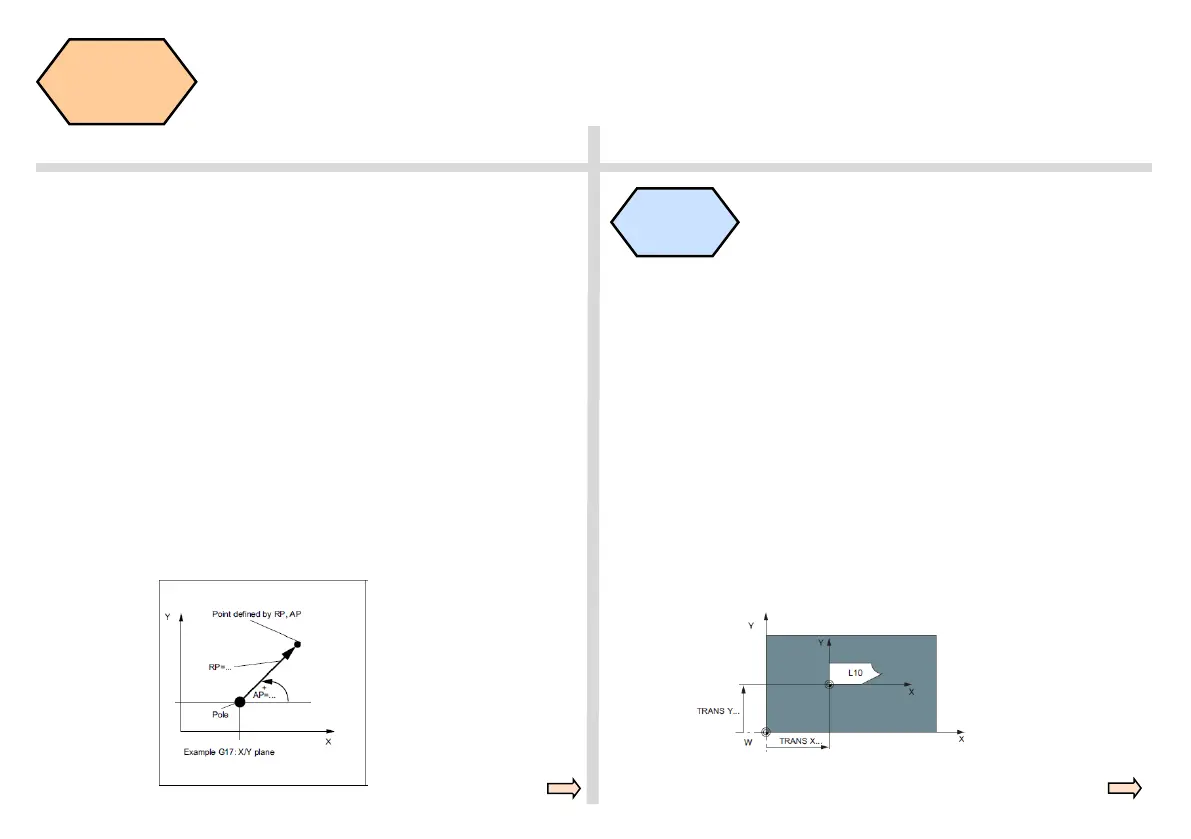

G110 Pole specification relative to the setpoint position last programmed

(in the plane, e.g. with G17: X/Y)

(when using G110, please always take the current position of the

tool as the reference point to specify the new pole)

G111 Pole specification relative to the origin of the current workpiece

coordinate system (in the plane, e.g. with G17: X/Y)

G112 Pole specification, relative to the last valid pole; retain plane

Programming example

N10 G17 ; X/Y plane

N20 G111 X17 Y36 ; pole coordinates in the current workpiece

AP=45 RP=50 coordinate system

...

N80 G112 X35.35 Y35.35 ; new pole, relative to the last pole as a

AP=45 RP=27.8 polar coordinate

N90 ... AP=12.5 RP=47.679 ; polar coordinate

N100 ... AP=26.3 RP=7.344 Z4 ; polar coordinate and Z axis(= cylinder

coordinate)

Additive

workpiece

offsets

Loading...

Loading...