840D/828D SINUMERIK Operate Page 7

B503

B503

Notes

Section 4

Rapid traverse motion

Code G01

The straight line interpolation is used to move the tool with an exactly de-

fined speed along a straight line from the current position to the pro-

grammed destination point.

All axes can be traversed simultaneously, in which case the resulting line

of motion can lie anywhere at an angle within the working space. For this

the control unit requires a specified feed rate which at the latest must be

defined under the address “F” in the block containing the Code G01.

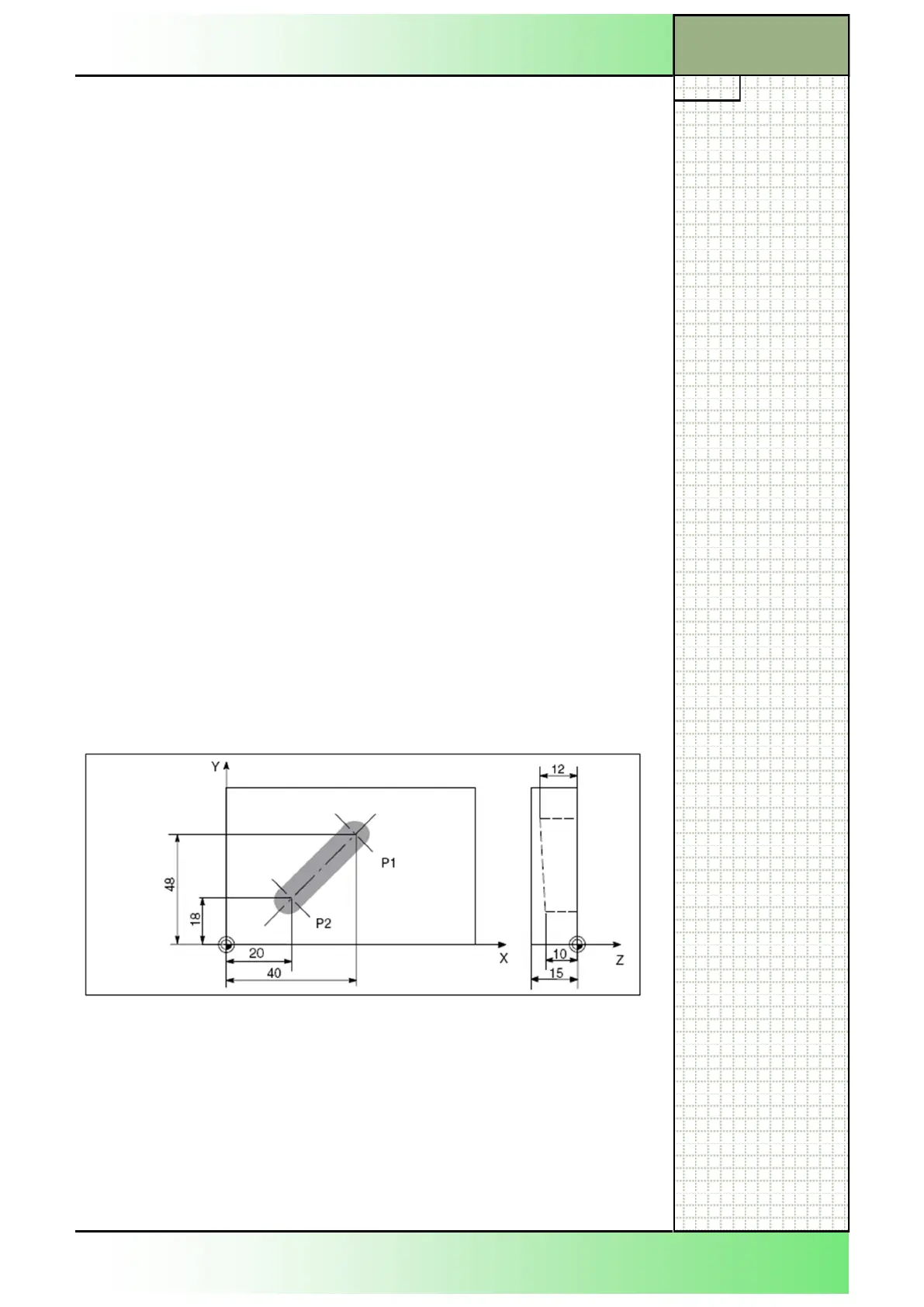

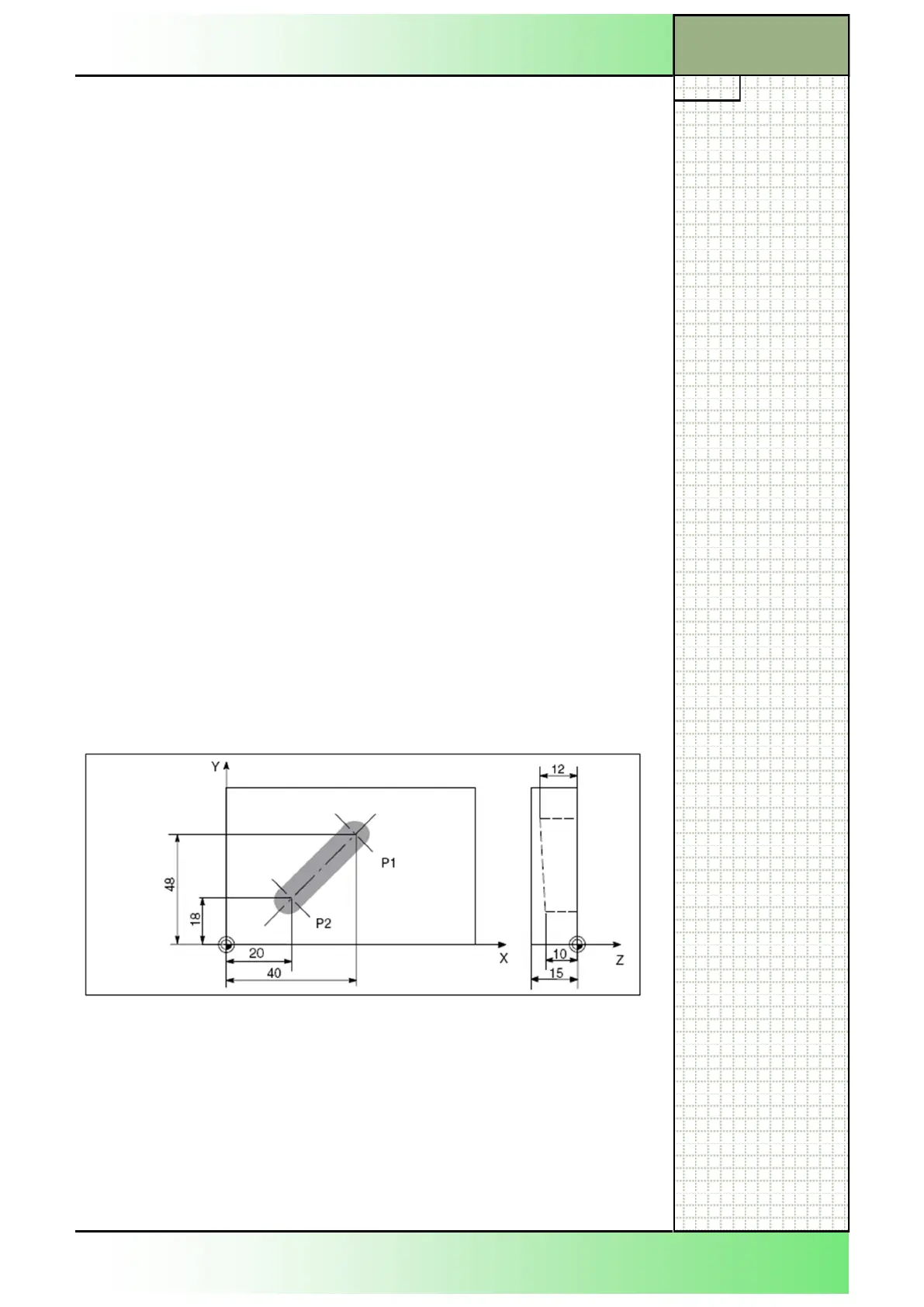

The following example describes the milling of a slot with absolute dimen-

sioning as per the drawing A shown below..

Programming example: Explanation:

N10 T1 ; End mill Tool call-up T1

N20 M6

N30 G94 F300 S2000 M3 D1 Technology block for the tool T1

with the cutting edge D1,

N40 G90 G00 X40 Y48 Z2 M8 With rapid traverse to the starting po-

sition P1 on the safety plane (absolute

dimensions),

N50 G01 Z-12 Plunging with feed rate,

N60 X20 Y18 Z-10 Milling the slot in 3 axes (G01 is

modally active),

N70 Z2 F1000 Retraction with increased feed rate

N80 G00 Z200

N90 M30

The following program extract shows the milling of the same slot using in-

cremental dimensioning: (up to N40 see above.)

….

N50 G91 G01 Z-14 Infeed along Z by –14 mm,

N60 G01 X-20 Y-30 Z2 Incremental traversing of the axes

N70 G90 Z2 F1000 Retraction with absolute dimensions

N80 G00 Z200

N90 M30

4.1 Straight line interpolation

Loading...

Loading...