840D/828D SINUMERIK Operate Page 5

B506

B506

Notes

The programming of the machining sequence can be achieved by means

of description of the individual steps using departure commands (e.g. G00,

G01, G02, etc.) or by means of machining cycles.

The following representation refers to the flow chart in Section 3 of this

manual and describes a possible machining sequence.

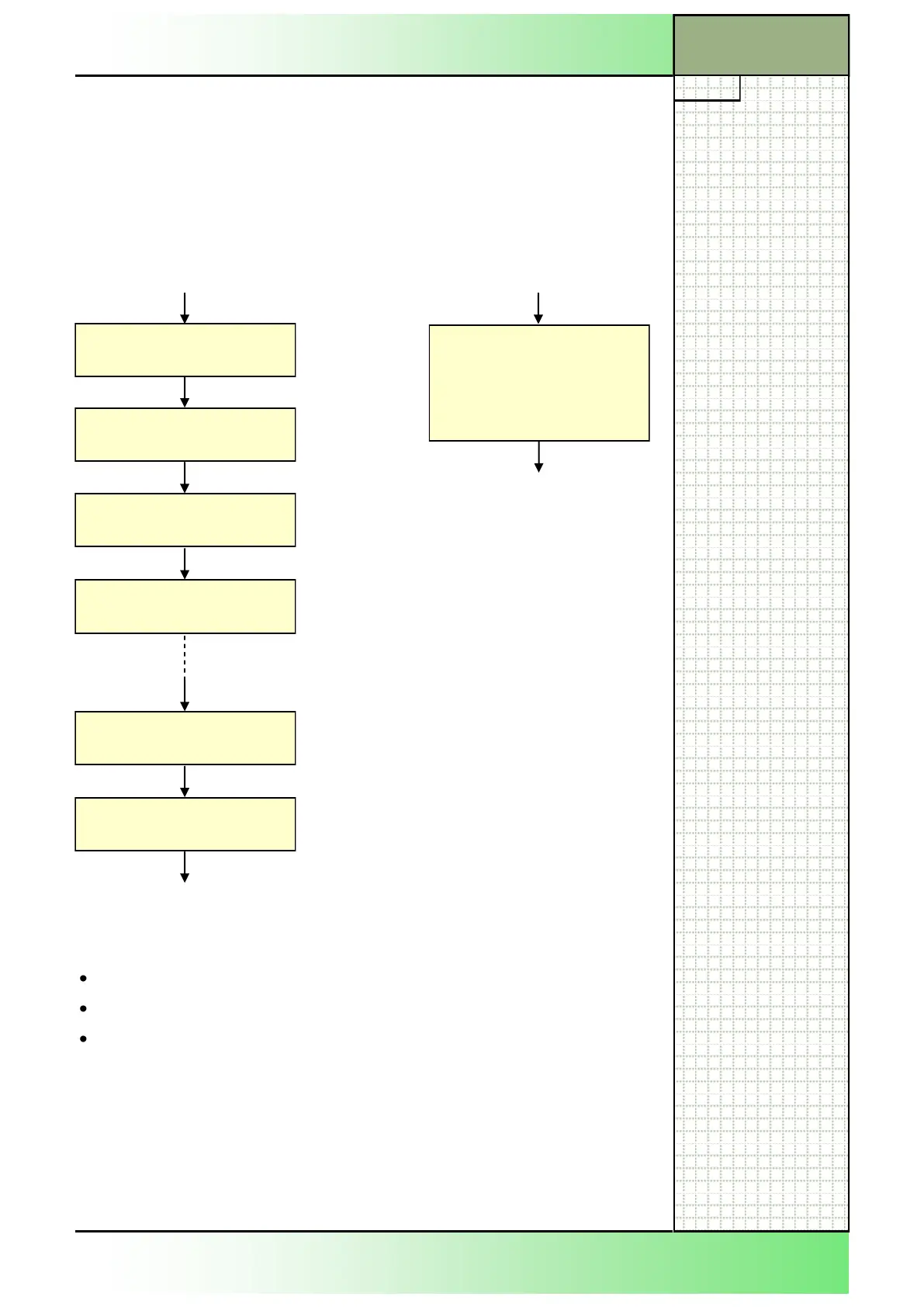

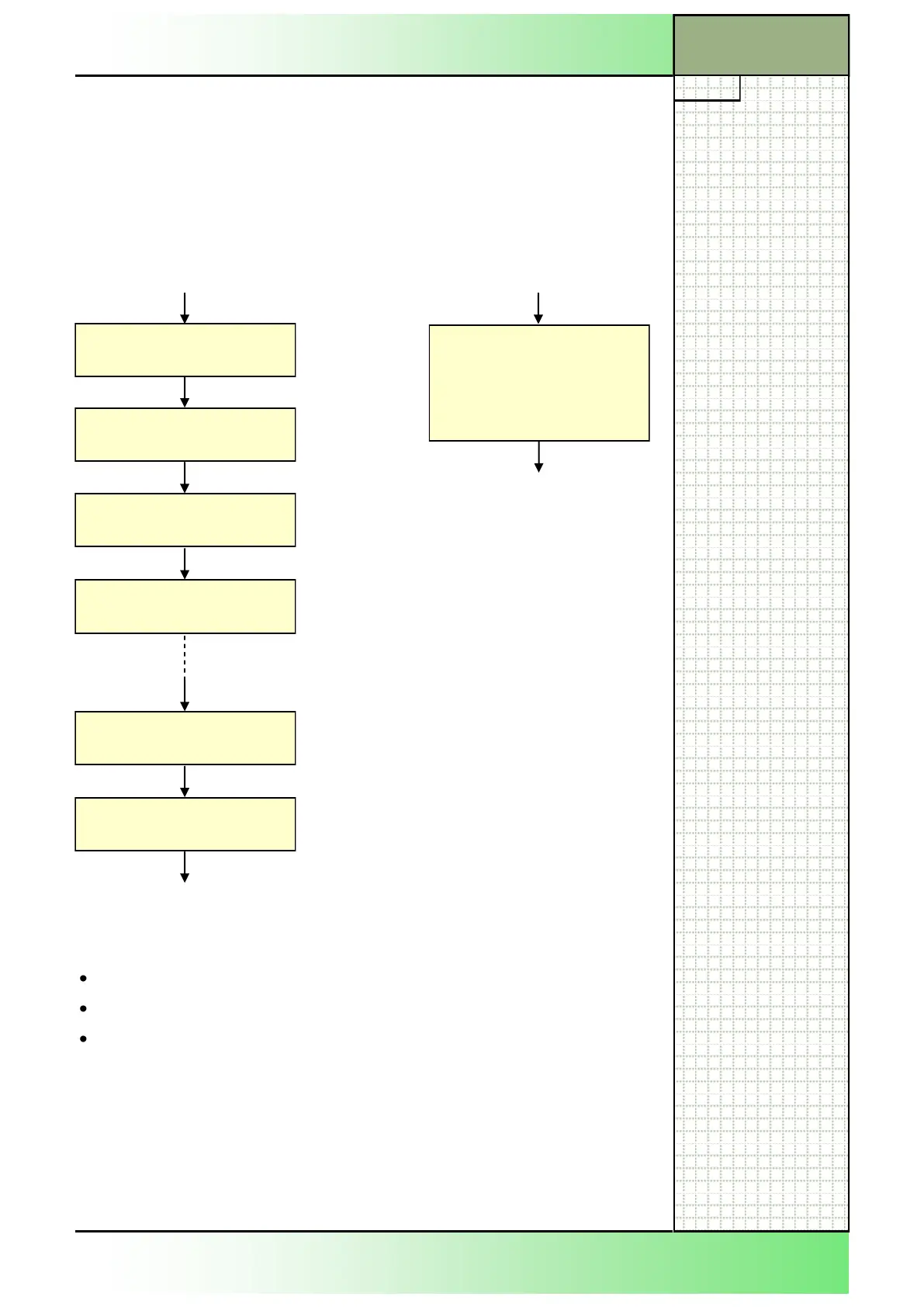

Programming with G-Codes Programming using cycles

The following criteria should be kept in mind when selecting between the

two described possibilities:

Availability of the cycles on the respective machine

Machining time required with cycles or with G-codes

The relation of the number of work pieces to the required programming

extent

Input of the individual para-

meters using the input

mask and graphical support

Activation of radius correc-

tion

Interpolation to the first de-

stination point

Interpolation to the next

destination point

Interpolation to the last de-

stination point

Deactivation of the radius

correction

Program structure of a machining sequence

Section 4

Loading...

Loading...