Procedure

1. The part program or ShopMill program to be processed has been created

and you are in the editor.

2. Press the "Milling" softkey.

3. Press the "Thread milling" softkey.

The "thread milling" input window opens.

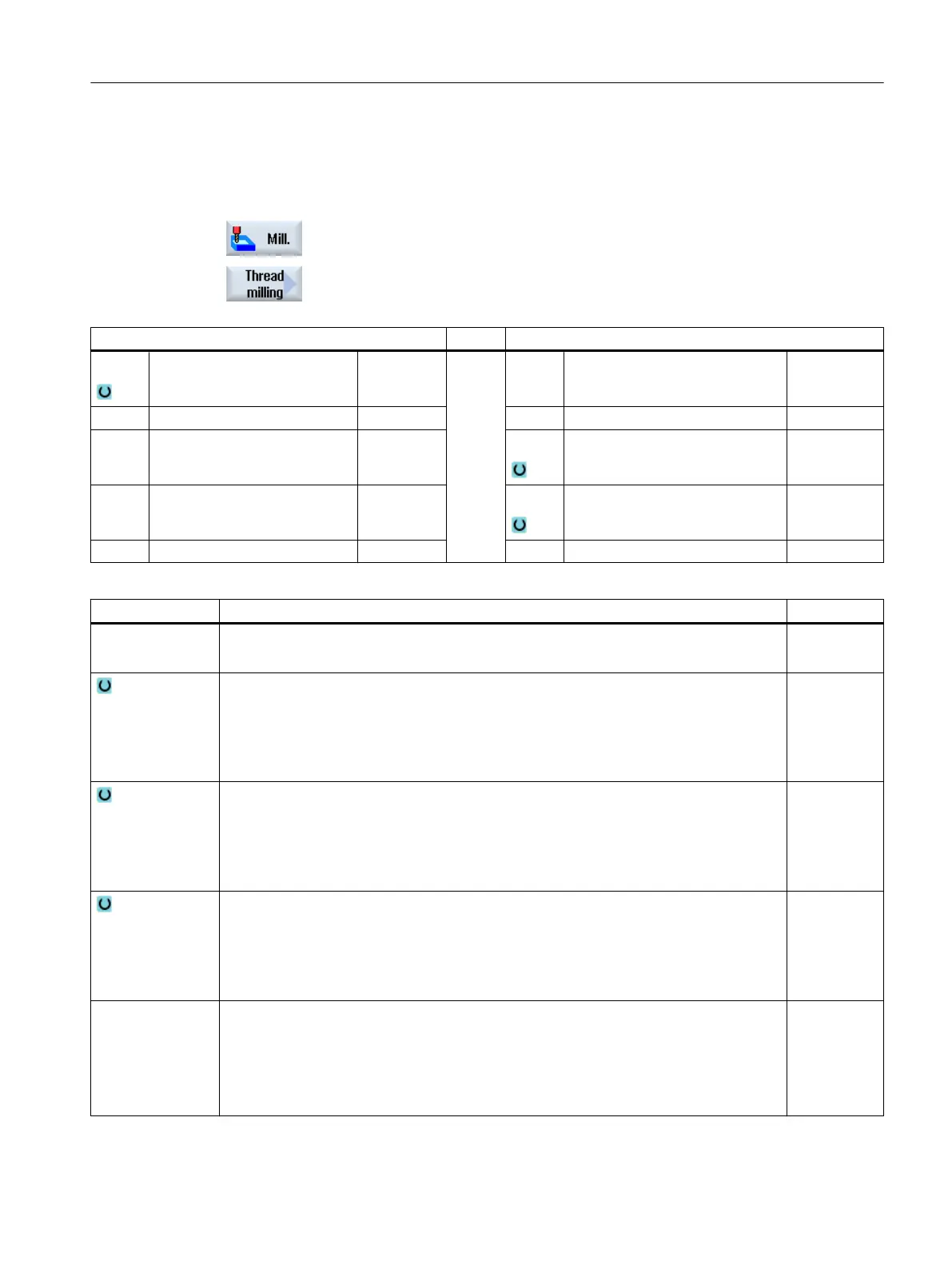

Parameters, G code program Parameters, ShopMill program

PL Machining plane T Tool name

RP Retraction plane mm D Cutting edge number

SC Safety clearance mm F Feedrate mm/min

mm/tooth

F Feedrate * S / V Spindle speed or constant cutting

rate

rpm

m/min

Parameter Description Unit

Machining

● ∇ (roughing)

● ∇∇∇ (finishing)

Machining direction:

● Z0 → Z1

Machining from top to bottom

● Z1 → Z0

Machining from bottom to top

Direction of rotation of the thread:

● Right-hand thread

A right-hand thread is cut.

● Left-hand thread

A left-hand thread is cut.

Position of the thread:

● Internal thread

An internal thread is cut.

● External thread

An external thread is cut.

NT Number of teeth per cutting edge

Single or multiple toothed milling inserts can be used. The motions required are executed

by the cycle internally, so that the tip of the bottom tooth on the milling insert corresponds

to the programmed end position when the thread end position is reached. Depending on

the cutting edge geometry of the milling insert, the retraction path must be taken into

account at the base of the workpiece.

Programming technological functions (cycles)

10.2 Milling

Milling

Operating Manual, 08/2018, 6FC5398-7CP41-0BA0 473

Loading...

Loading...