Functional safety for SIPART PS2 FF

34 A5E00489774-02, 10/2013

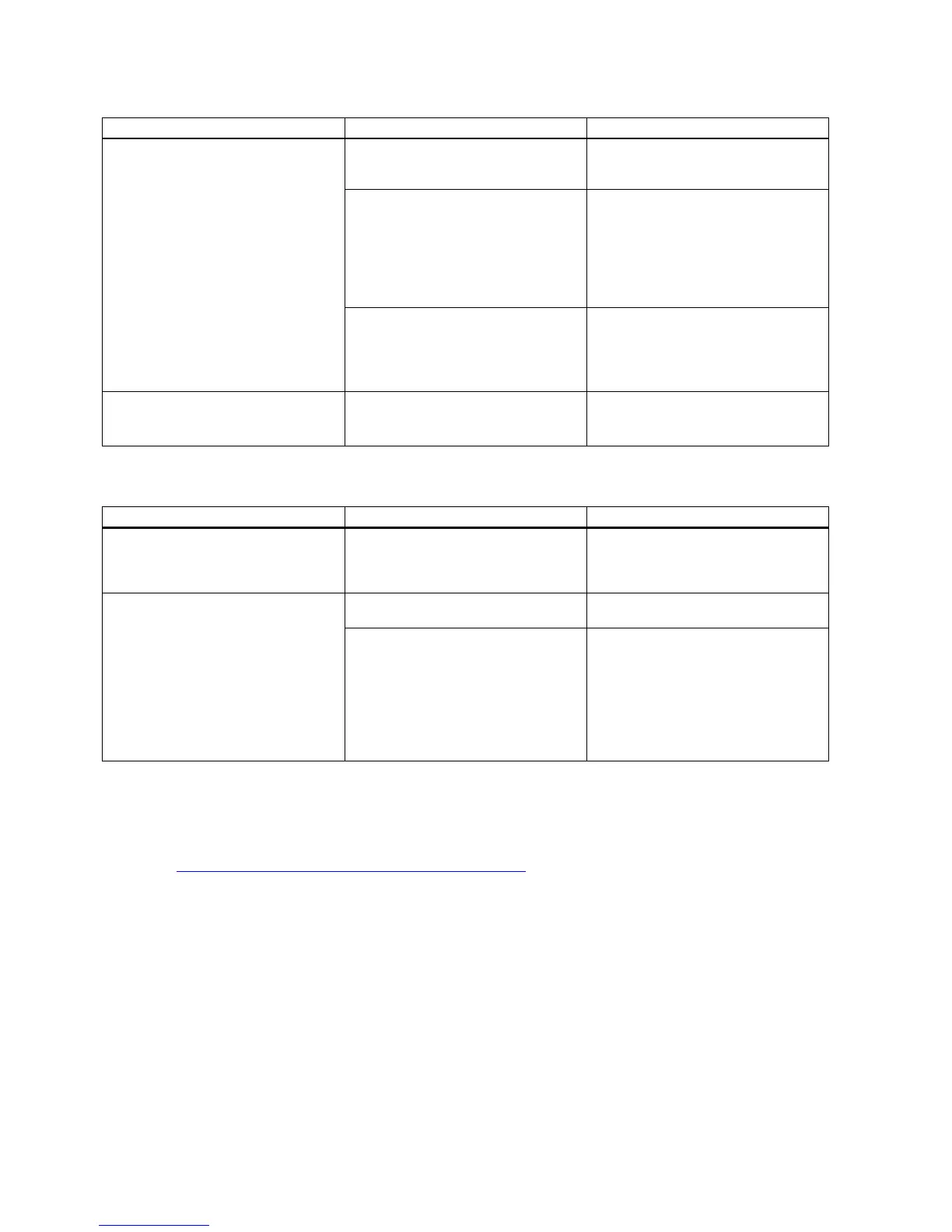

Remedial measures table 4

● In stationary automatic mode

(constant setpoint) and in manual

mode, both piezo valves continually

switch alternately, and the actuator

oscillates around a mean value.

●

Sticking friction of the packing gland

from the control valve or actuator

● Reduce friction or increase dead

zone of positioner (parameter

"dEbA") until the oscillation stops.

● Looseness (play) in the

positioner/actuator/control valve

system

● Part-turn actuator: Check for firm

seating of set screw on coupling

wheel.

● Linear actuator: Check for firm

seating of lever on positioner shaft.

● Correct any other play between the

actuator and the control valve.

● Actuator too fast ● Increase actuating times using

throttle screws.

● If a quick actuating time is needed,

increase the dead zone (parameter

"dEbA") until the oscillation stops.

● Positioner doesn't move control

valve to the stop (at 20 mA).

● Supply pressure too low. Load on

the feeding controller or system

output is too low.

● Increase supply pressure, insert

ballast converter

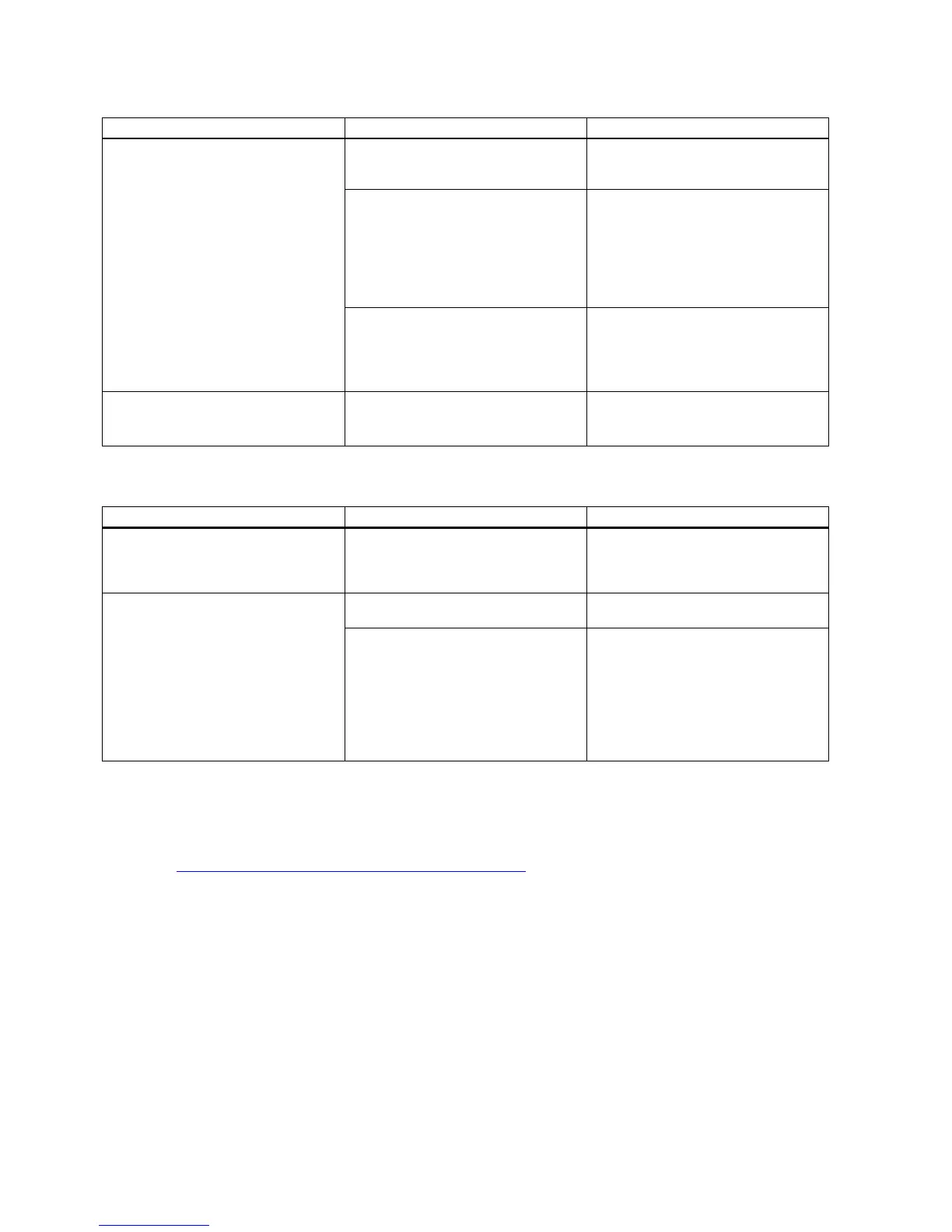

Remedial measures table 5

Zero point displaces sporadically

Impact or shock loads result in

accelerations so high that the

friction clutch moves, e.g. due to

"vapor shocks" in vapor lines.

Rectify the causes for shock loads.

● Re-initialize the position controller.

● The device function has completely

failed: No representation on the

display either.

● Electrical auxiliary power supply is

● Check the electrical auxiliary power

● In case of very high continuous

loads due to vibrations

(oscillations):

● Screws of the electrical connecting

terminals may be loosened.

● Electrical connecting terminals

and/or electronic components may

● Tighten the screws firmly and

secure using sealing wax.

● Repair

● For prevention: Install the positioner

on the damping pads.

The certificates can be found on the enclosed CD and on the Internet under:

Certificates (http://www.siemens.com/processinstrumentation/certificates)

Loading...

Loading...