I. 2-STROKE THROTTLE PUSHRODS:

The throttle pushrod for typical 2-stroke engines is the traditional

push-pull type, cut to length, with metal control links at each end.

a) From the kit contents, locate the 16” length of inner nylon

pushrod tubing, two M2 x 7/8” threaded studs and two metal

control links. Use an electric drill to thread one of the studs about

1/4” into one end of the nylon pushrod. Thread a metal control link

onto the threaded stud and insert the unprepared end of the

pushrod into the tube pushrod housing protruding from the firewall.

Snap the metal control link onto the throttle arm of your engine.

b) Look at your engine to determine which direction the

throttle arm must travel to be in the full throttle position - using the

transmitter, set the direction of travel for the throttle servo

accordingly.

c) Thread the remaining stud into the remaining metal control

link. Snap the link onto the outermost hole in throttle servo output

arm. Use a marker pen to mark the nylon pushrod where it should

be cut and still accept about 1/4” of the threaded stud. Disconnect

the metal link from the servo arm and remove the pushrod from the

fuselage tube. Cut the tubing at the mark just made. Unthread the

stud from the metal link and use the electric drill to thread the stud

into the end of the pushrod, about 1/4”.

d) Re-insert the pushrod into the fuselage from the firewall.

Thread the metal link onto the stud in the servo compartment.

Connect the front metal link to the throttle pushrod arm on the

engine and turn on the radio system. Adjust the metal link in the

servo compartment as needed to achieve full and low throttle

settings with the transmitter. Note that in some cases, this may

require moving the metal link on the servo output arm. As done

with the elevator and rudder pushrods, apply a drop of thin CA glue

to the threads on the stud and control link at the engine end of the

pushrod to keep the pushrod from twisting. Last, apply a drop or

two to the firewall where the throttle tube housing exits, to lock the

outer tube in place.

II. 4-STROKE THROTTLE PUSHRODS:

The throttle pushrod for 4-stroke engines is almost exactly the

same as it is for 2-stroke engines. The difference has to do with

the rear throttle arm location on most 4-stroke engines. Because

of this, the pushing and pulling of the pushrod, from the rear, must

be changed to get the same action from the front. To do this, it is

necessary to make a pushrod - in the engine compartment - that

reverses the action of the servo at the engine throttle arm. We do

this by replacing the 7/8” threaded stud with a longer wire pushrod

that’s threaded at one end. Also, it is important that the engine

throttle arm is facing upwards, toward the head of the engine. This

throttle arm position allows it to be more easily accessed for

attachment of the metal control link. Every engine we tested for

this model allowed repositioning of the throttle arm.

a) From the kit contents, locate the 16” inner nylon pushrod, a

M2 x 7/8” threaded stud, a metal control link, a 10” metal pushrod

wire (threaded at one end) and a metal solder link (no internal

threads). Use the electric drill to thread the 10” metal pushrod into

one end of the nylon pushrod - about 1/4”. You will also need a

soldering iron and solder.

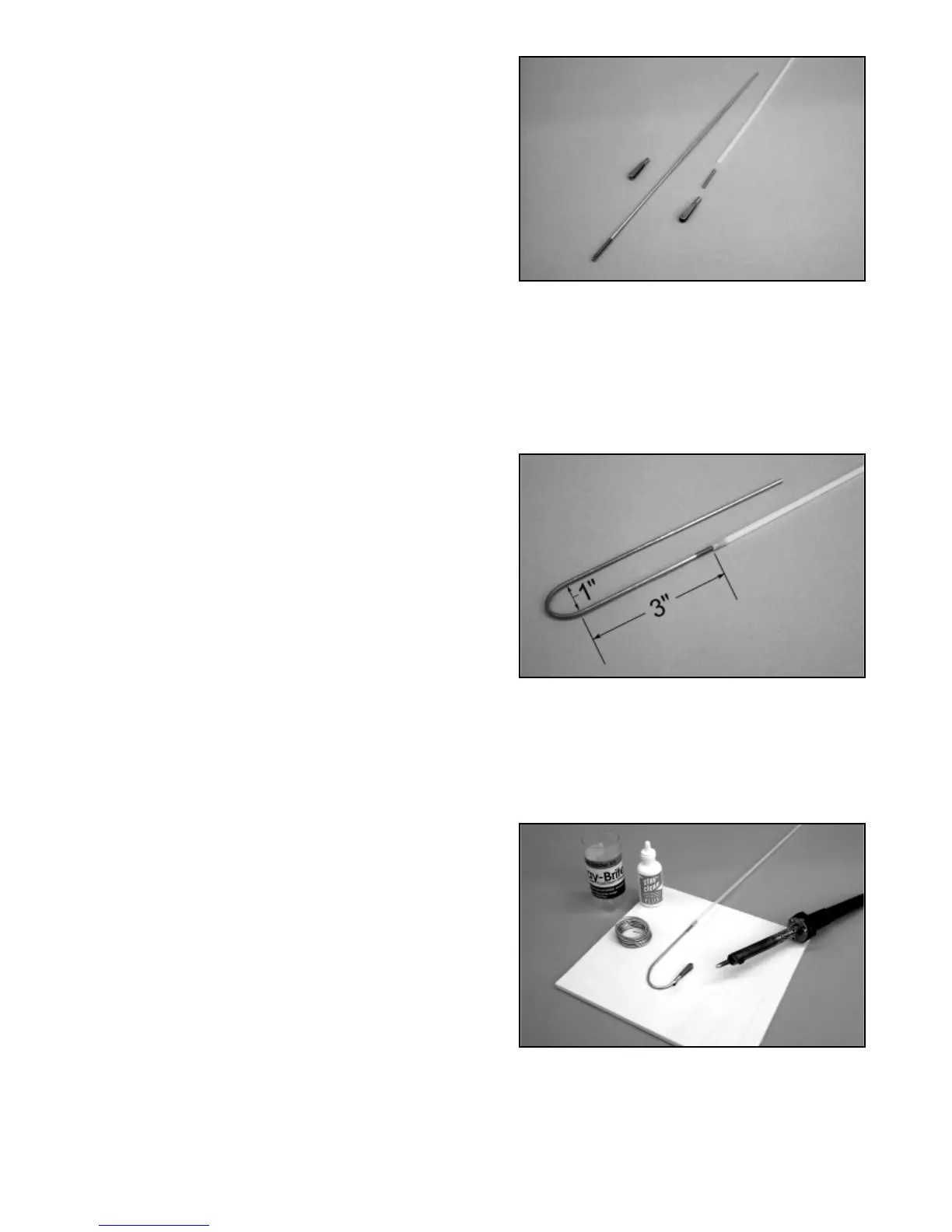

b) With the 10” pushrod threaded into the nylon pushrod,

measure 3” from the front face of nylon pushrod, out onto the metal

pushrod and mark the point with a marker pen. This is the point

where you will begin to make a 180

O

bend in the metal pushrod

wire. The diameter of this bend should be the same as the

distance from the center of the pushrod exit in the firewall to the

hole in the engines throttle arm. For example, this distance

measured 1” on our Magnum .52. Therefore, we bent the pushrod

180

O

, leaving a 1” spacing.

c) The end of the wire that reverses back toward the nylon

tube is now cut, leaving just enough wire to slip the solder link in

place. Cut the wire with a carbide cut-off wheel and slip the solder

link in place. Solder the link in place to the wire with the arms of

the link facing toward each side of the wire in top view. This

position allows the two arms of the link to be spread and placed

onto the throttle arm.

d) Insert the unprepared end of the nylon pushrod into the

tube protruding from the firewall, all the way back to the servo

compartment. Use needle nose pliers or hemostats to connect the

solder link to the throttle arm on the engine. From the servo

compartment, test the action of the pushrod and adjust the bend

as needed to obtain a smooth throttle movement.

17

Loading...

Loading...