If choosing lithium battery for the controller, you are allowed to use the lithium battery only which have configured. There're

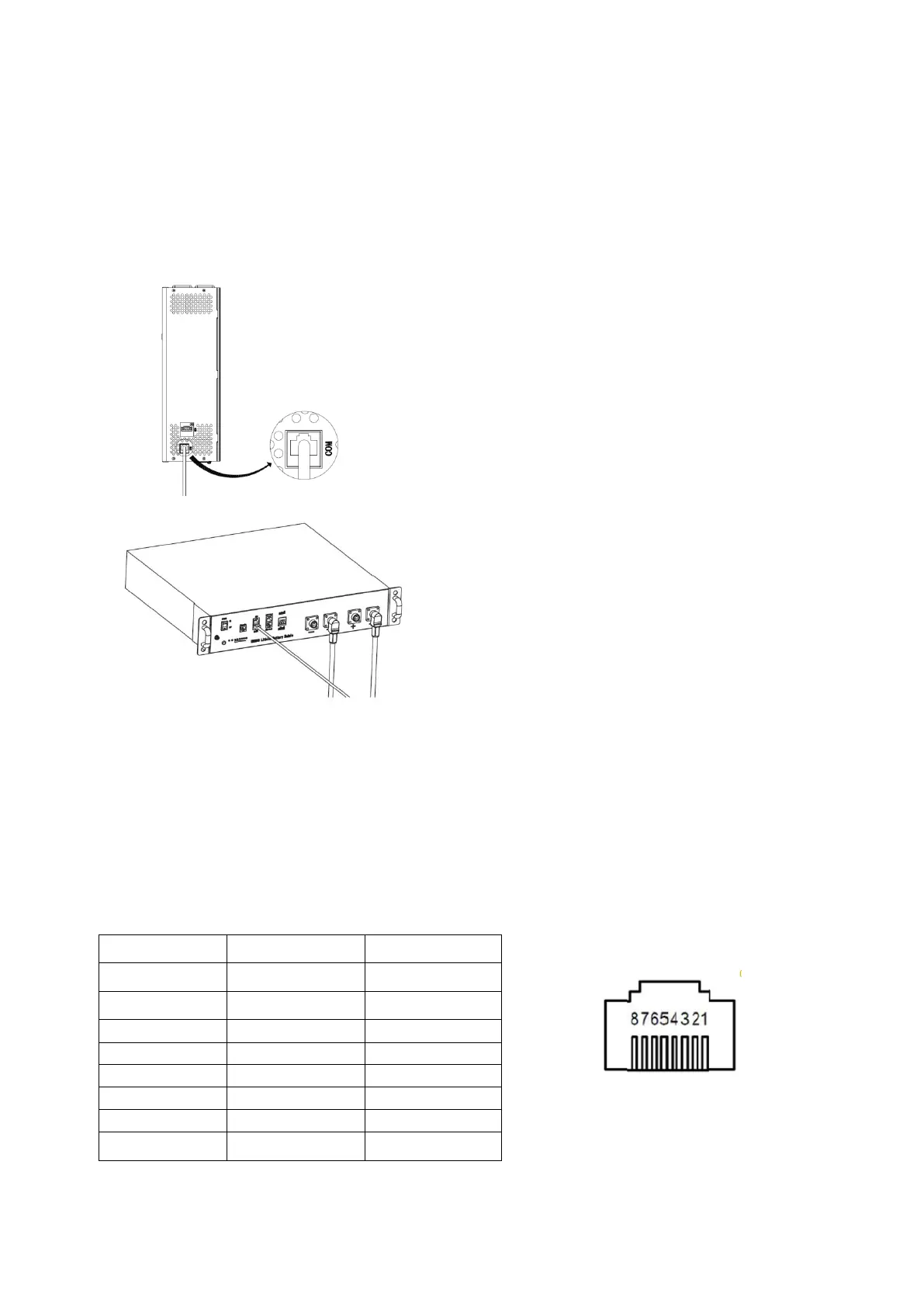

two connectors on the lithium battery, RJ45 port of BMS and power cable.

Please follow below steps to implement lithium battery connection:

1. Assemble battery ring terminal based on recommended battery cable and terminal size (same as Lead acid, see section

Lead-acid Battery connection for details) .

2. Insert the ring terminal of battery cable flatly into battery connector of inverter and make sure the bolts are tightened with

torque of 2-3Nm. Make sure polarity at both the battery and the inverter/charge is correctly connected and ring terminals are

tightly screwed to the battery terminals.

3. Connect the end of RJ45 of battery to the communication port of the controller.

4. The other end of RJ45 insert to battery comm port.

Note: If choosing lithium battery, make sure to connect the BMS communication cable between the battery and the controller.

You need to choose battery type as “lithium battery”

Lithium battery communication and setting

In order to communicate with battery BMS, you should set the battery type to “LI” in Program 2. Then the LCD will switch to

Program 21, which is to set the protocol type. There are several RS485 protocols in the controller which can match some

customized battery, Please consult with supplier first before you choosing the battery model.

1. Connecting the communication port between the controller and battery

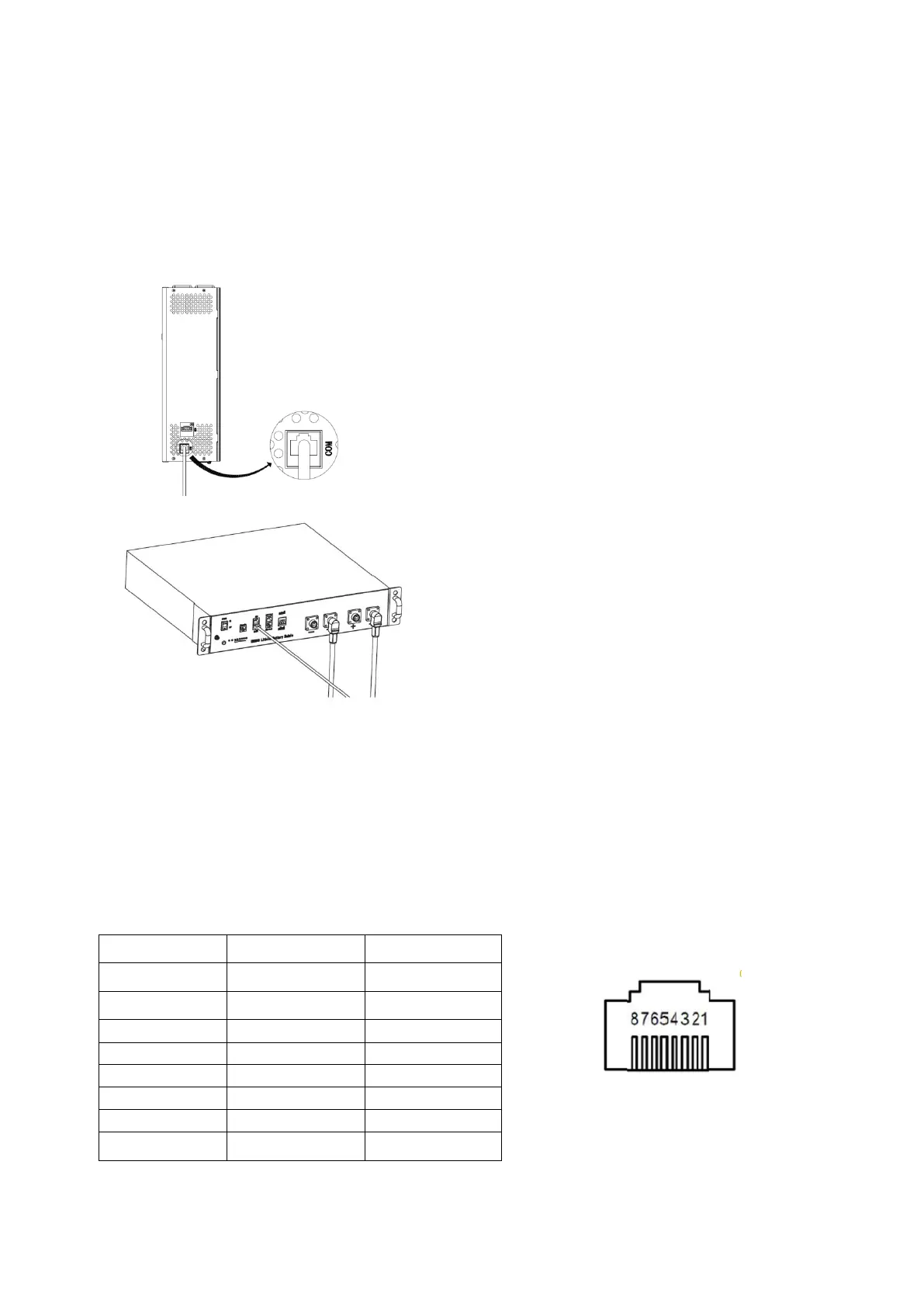

Make sure the lithium battery BMS port connects to the controller is Pin to Pin, the controller communication port pin

assignment shown as below (“COM” port on the controller, support RS485 or CAN protocol).

2. LCD setting

To connect battery BMS, need to set the battery type as “LI” in Program 02. After set “LI” in Program 02, it will switch to

Program 21 to choose battery type. There will be some options under Program 21.

Loading...

Loading...