Battery Connection

CAUTION: For safety operation and regulation compliance, it’s requested to install a separate DC over-current

protector or disconnect device between battery and controller. It may not be requested to have a disconnect device in

some applications, however, it’s still requested to have over-current protection installed. Please refer to typical

amperage in below table as required fuse or breaker size.

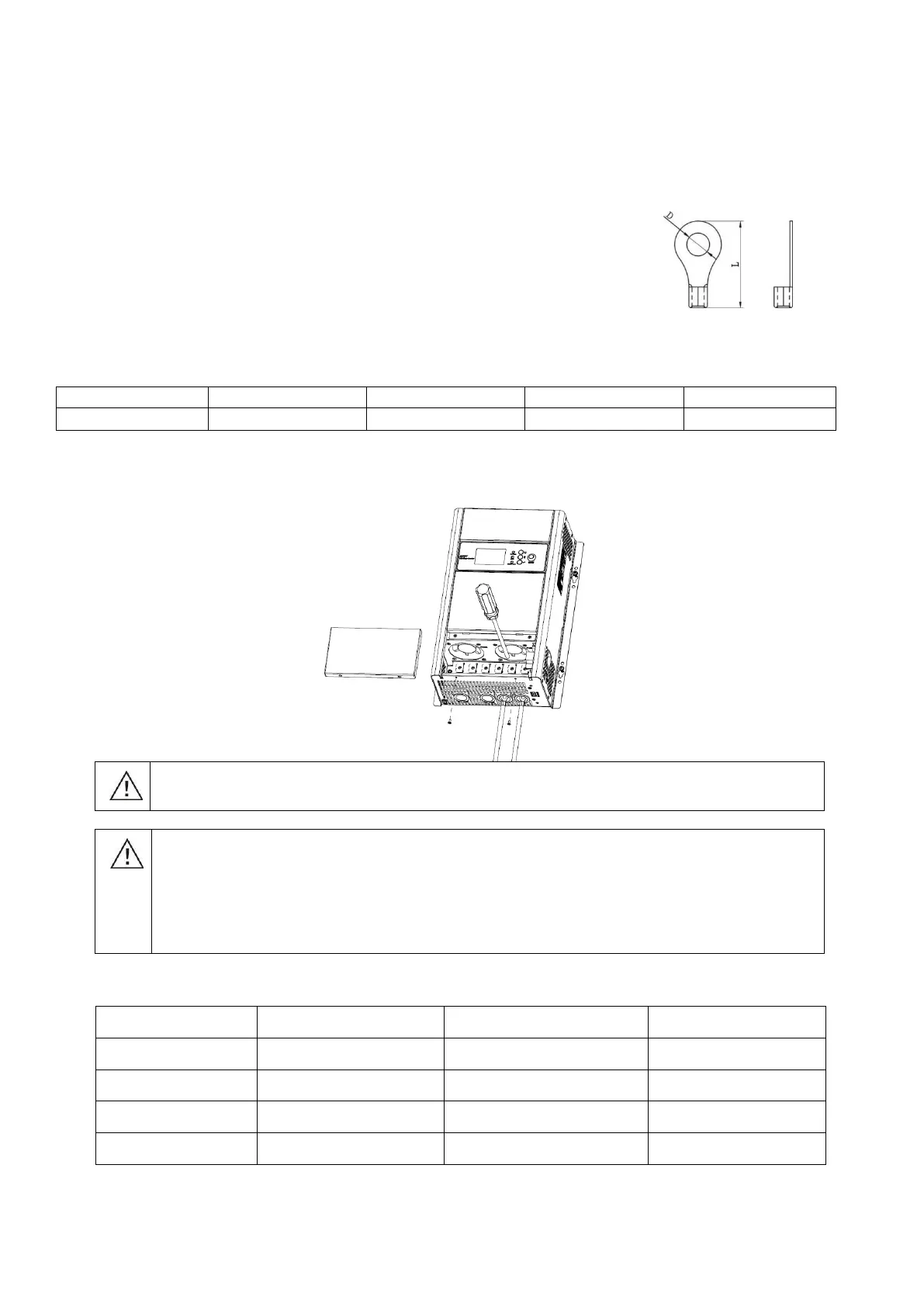

Ring terminal:

WARNING! All wiring must be performed by a qualified person.

WARNING! It's very important for system safety and efficient operation to use

appropriate cable for battery connection. To reduce risk of injury, please use the

proper recommended cable and terminal size as below.

Note: For the lead acid battery, the recommended charge current is 0.2C(C-battery capacity). Please follow below steps to

implement lead-acid battery connection:

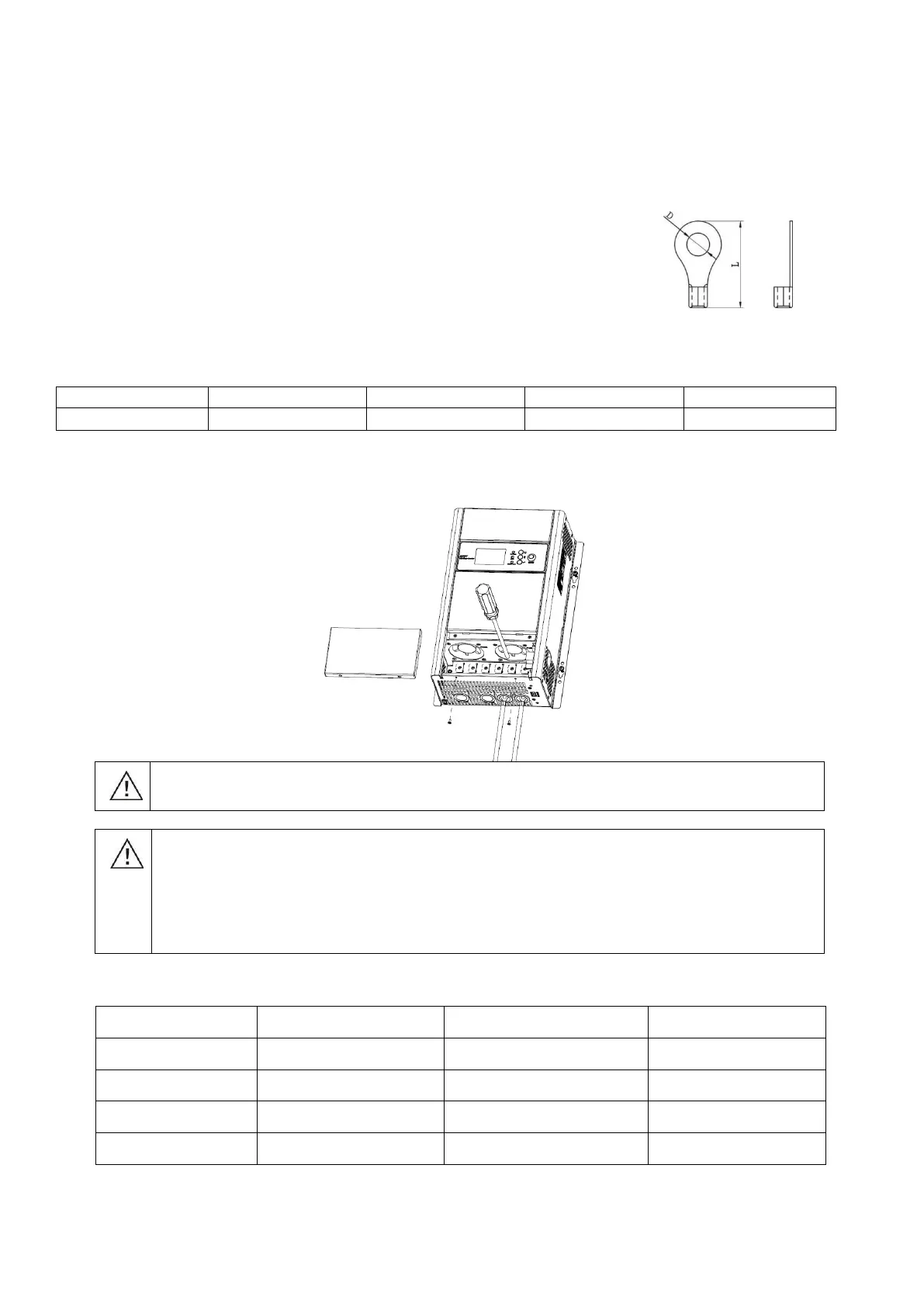

1. Assemble battery right terminal based on recommended battery cable and terminal size.

2. Connect all battery packs as units requires. It’s suggested to connect at least 550Ah capacity battery for 48V/120A model.

Insert the ring terminal of battery cable flatly into battery connector of controller and make sure the bolts are tightened with

torque of 2-3Nm. Make sure polarity at both the battery and the controller is correctly connected and ring terminals are tightly

screwed to the battery terminals.

WARNING: Shock Hazard

Installation must be performed with care due to high battery voltage in series.

CAUTION!! Do not place anything between the flat part of the controller terminal and the ring

terminal. Otherwise, overheating may occur.

CAUTION!! Do not apply anti-oxidant substance on the terminals before terminals are connected

tightly.

CAUTION!! Before making the final DC connection or closing DC breaker, be sure positive (+) must

be connected to positive (+) and negative (-) must be connected to negative (-).

Recommended cable size:

Lithium Battery Connection

Loading...

Loading...