Page 3:X

SIGMA TANDEM SYSTEM OWNER’S MANUAL

11301 - 00.00.0000 Section 2: Equipment • Chapter 4 - Packing & Closing the Main

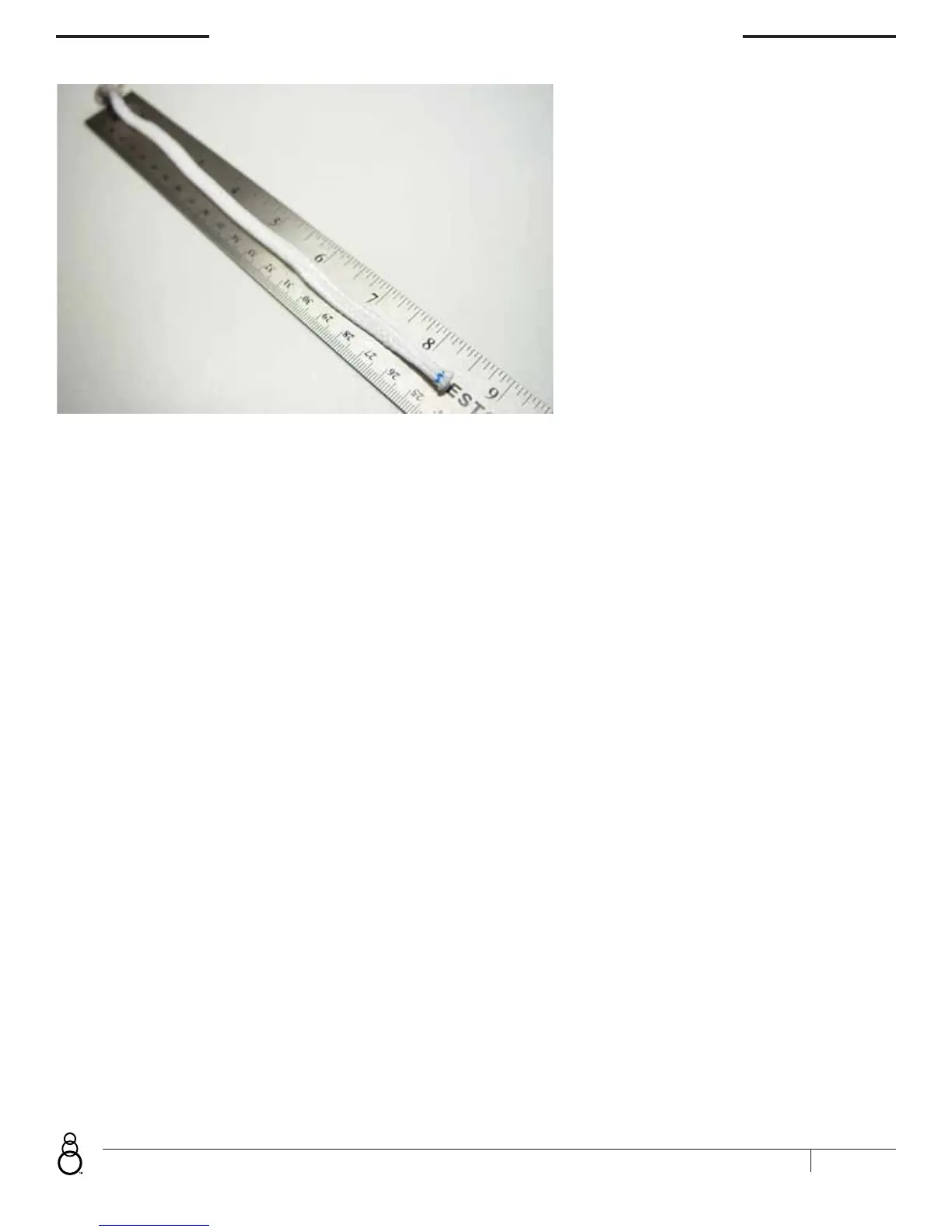

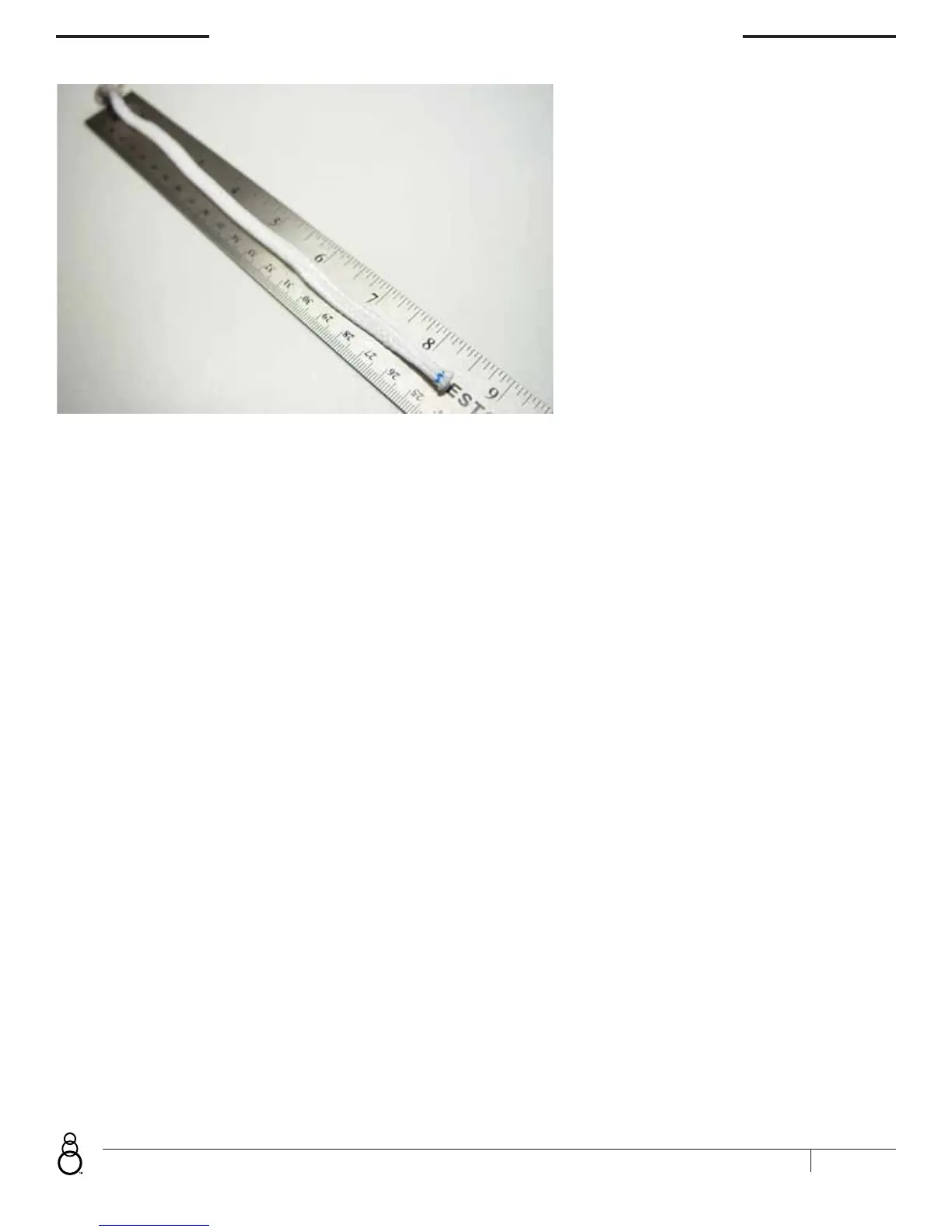

INSPECT MAIN CLOSING LOOP

The main container-closing loop is also

constructed of 1,000 lb. Spectra line, and

finished to a set length. Spectra is used

because of its low surface friction. Any other

line (other than Teflon, which is too weak)

would cause a hard or impossible pull in this

application.

The “sewn to button” construction technique

is used because knots in Spectra slip, and

there is only one correct length (8½ ”) for the

closing loop anyway. However, Spectra has a

low melting temperature, so the pull-up cord

used to close this rig must also be Spectra.

Friction caused by the use of Nylon or Dacron

pull-up cords, even when extreme care is taken, will very quickly damage the container closing loop. Replace any loop,

which is badly worn. It is not necessary to replace a loop that is just slightly fuzzy. With proper care a loop can last 100

jumps or more. If you insist on using nylon pull up cords, your closing loop must be replaced every few jumps. This can

get expensive. Spare loops and pull-up cords are stored in the main top flap pouches.

WARNING:

Do not fabricate your own closing loops.

Do not use anything but Spectra as a pull-up cord.

INSPECT THE DROGUE RELEASE RECOIL RIPCORD SYSTEM

Make sure the eyeleted stainless steel pin is straight and free of burrs. Pull all slack Spectra ripcord up out of the

housings, remove any twists, and check for wear. Each ripcord is independent of the other; over 1,000 lbs. strong, and

only sees 10 lbs. in use. So a small amount of wear is nothing to be concerned about. Pull each ripcord handle to check

the recoil function, and examine the loop-to-loop connection at each handle for wear. Make sure the ripcord housings

are secure.

INSPECT THE CANOPY

1) bridle attachment point on top and inside of canopy

The bridle attachment point at the top of the canopy is a very high wear point and should be checked for any signs of

damage occurring to the stitching both on top and inside of the canopy.

2) canopy cells, panels and seams

As you flake the canopy, take a good look at each panel for any tears, burns or broken stitches. After every 25 jumps

inspect the canopy more closely to include looking inside the cells as well as inspecting all of the reinforcing tapes

through-out the canopy.

3) line condition and attachment points

During the flaking of the canopy, take a look down the length of the lines watching for any damage or deformities.

Every so often walk down the length of the lines inspecting all cascade points and looking for any burns or broken

stitching.

Loading...

Loading...