www.ssimder.com

Before starting any welding activity ensure that you have suitable eye protection and protective

clothing. Also take the necessary steps to protect any persons within the area.

3.1 MMA Welding Mode

After connecting the welding leads as detailed you will need to switch the power switch on the

back panel to “ON”

Select MMA by switching to the MMA welding mode. There is voltage output at both output

terminals. Set the amperage on the machine suitable for the electrode being used. Ensure you

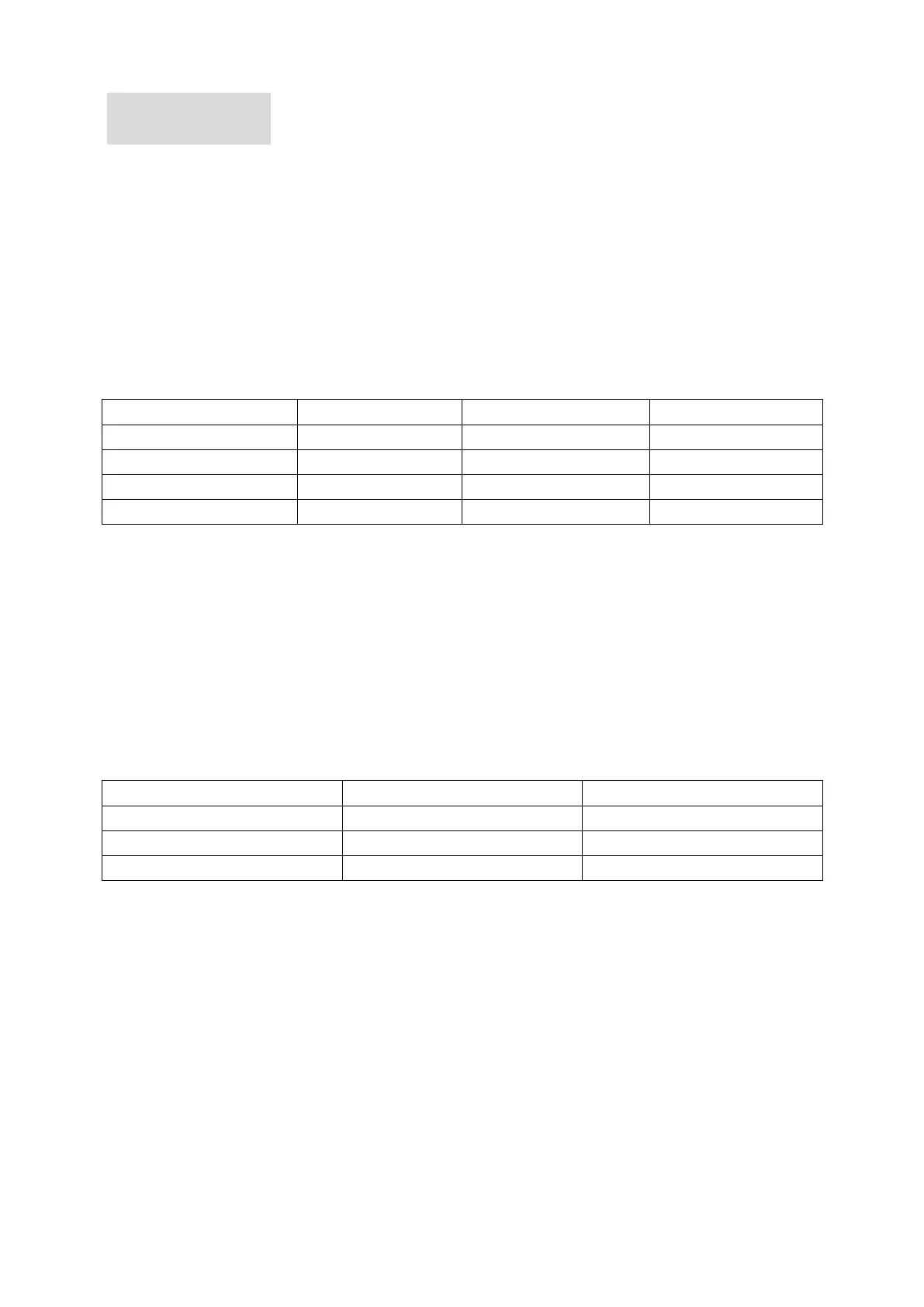

check that you have the electrode polarity correct. Please see below a guide to amperage

required.

3.2 MIG Welding Mode

Switch the welding mode to 0.8mm flux core or 1.0mm flux core welding mode based on the wire

you were using.

Adjust the “Voltage knob” on the front panel to get proper welding voltage. We will suggest to

start with 50% if you are beginner.

The “Current knob” for wire feeding speed adjusting, we will suggest to start with 30% if you

are beginner. Then Operate the torch trigger, and you can start welding.

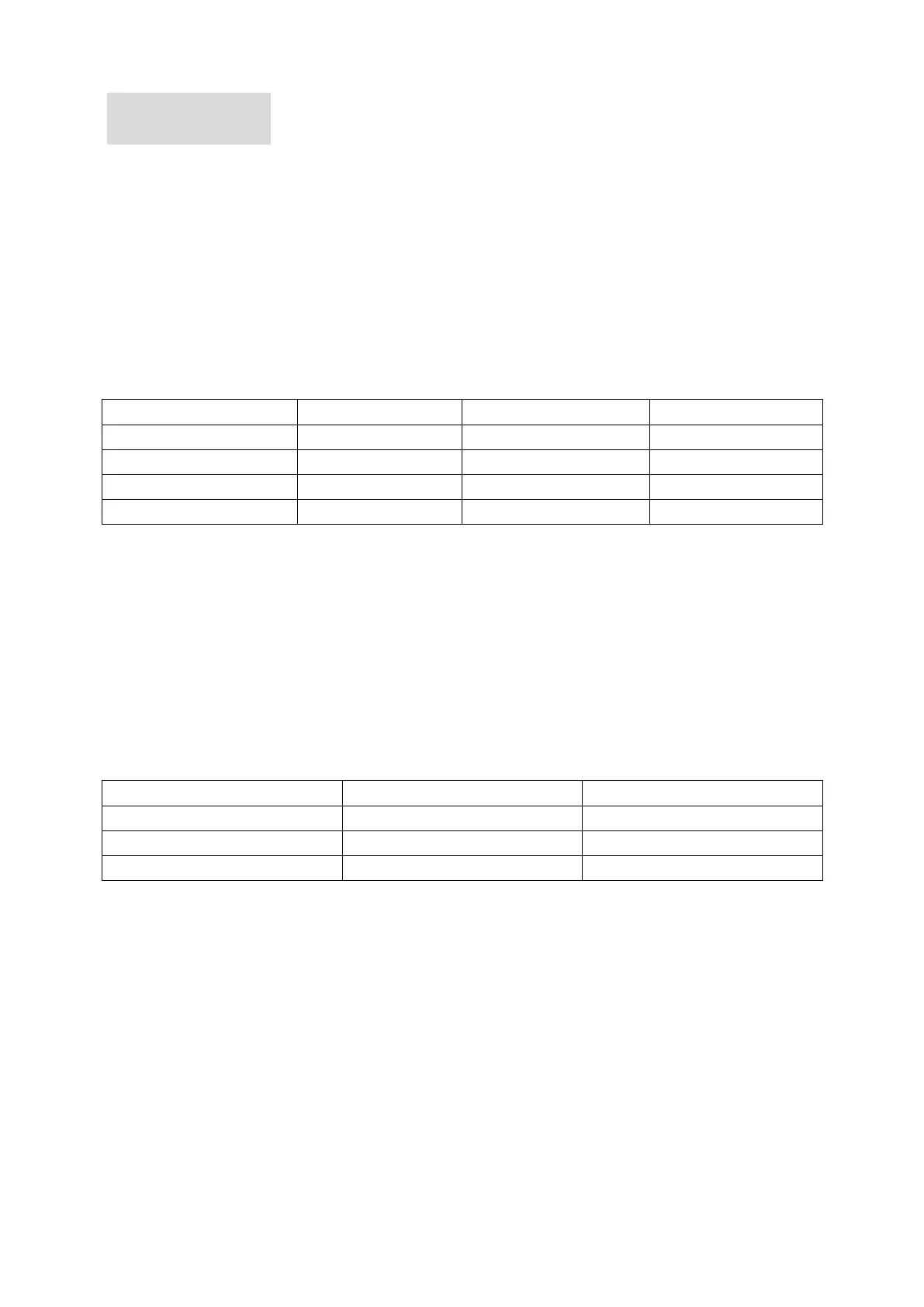

Set the welding current after the above preparation. Short circuiting transfer is mainly fit for

electrode wires of diameter flux 0.8/1.0 mm. As a guide for short circuit welding set the welding

current according to the table below.

1) Welding speed selecting

The welding quality and productivity should be taken into consideration for the selecting of welding

speed. In the case that the welding speed increases, it weakens the protection effect and quickens

the cooling. As a consequence, it is not good for weld bead shaping. In the event that the speed is

too slow, the work-piece will be burned through, and a good weld bead will be unavailable. In

practical operation, the welding speed should not exceed 50cm/min.

2) Wire Stick-out

The increase of the stick-out can improve the productivity, but too long stick-out may lead to

excessive spatter, wire breaking and unstable welding. Generally, the stick-out should be 10

times as the welding wire diameter.

Loading...

Loading...