53

4.1 GAS VALVE

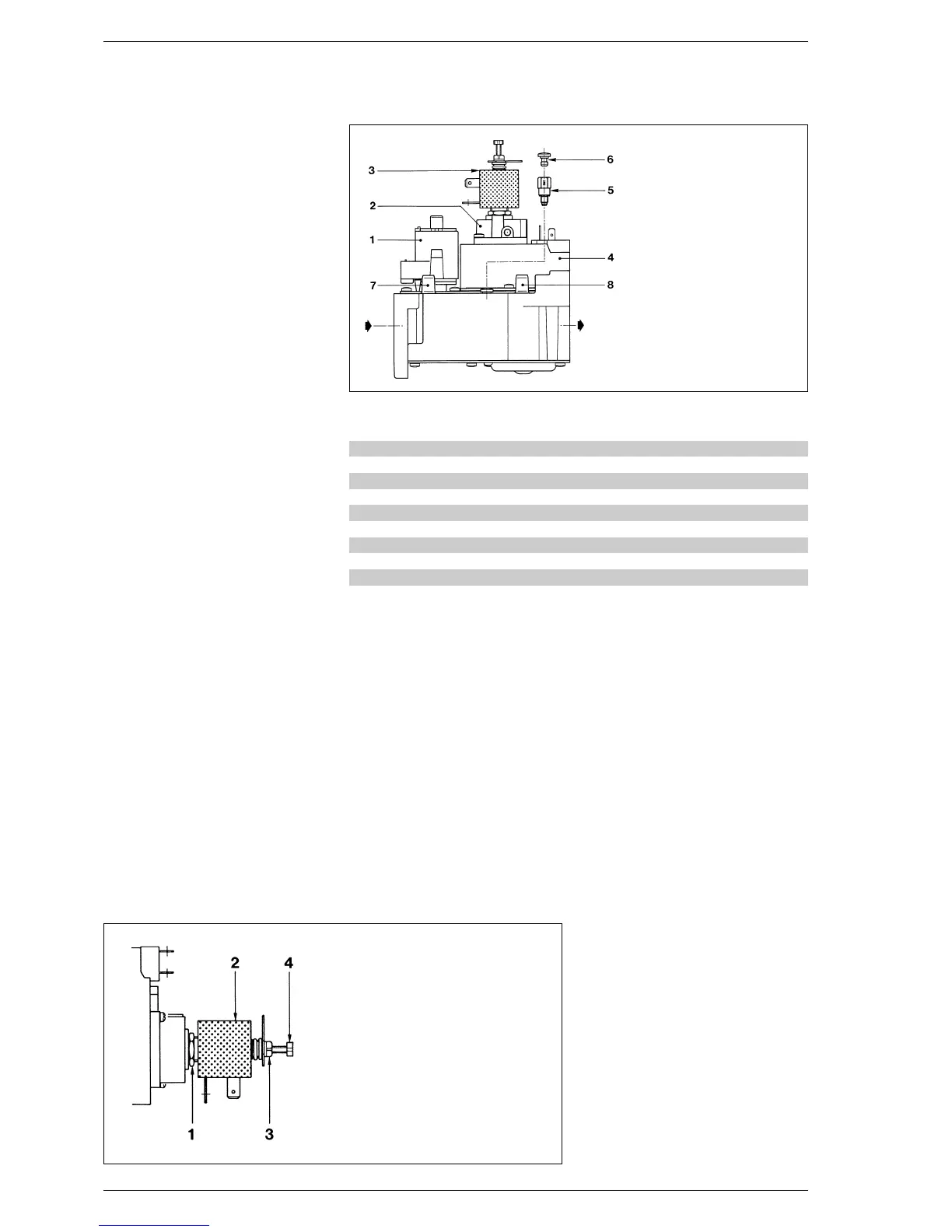

“RMG Mk.II” boilers come equipped

standard with a HONEYWELL VR

4605 C gas valve (for “70 - 80”

models) and VR 4605 CB gas valve

(for “90 - 100” models).

When the boiler is ignited the first

time, it is always recommended to

bleed the piping by using the pressu-

re outlet upstream from the valve

(fig. 10).

4.2 GAS VALVE ADJUSTMENT

T

he “RMG Mk.II” boilers have the gas

valve equipped with a coil assembly,

which enables, via the double-contact

regulating thermostat, a reduction in

output corresponding to approx. 60%

of nominal output before the burner

goes out completely. Calibration of the

operating pressures is done by SIME in

the factory. Consequently they should

not be altered. Only when you switch to

another type of gas (butane or propa-

ne) is it permitted to alter the opera-

ting pressures (Table 1).

It is essential that this operation be

carried out exclusively by authorized

technical staff. When the working

pressures have been adjusted, reseal

the regulators.

When the gas pressures are to be

reset, this must be done following a set

order: first the maximum pressure and

then the minimum.

4.2.1 Nominal pressure

adjustment

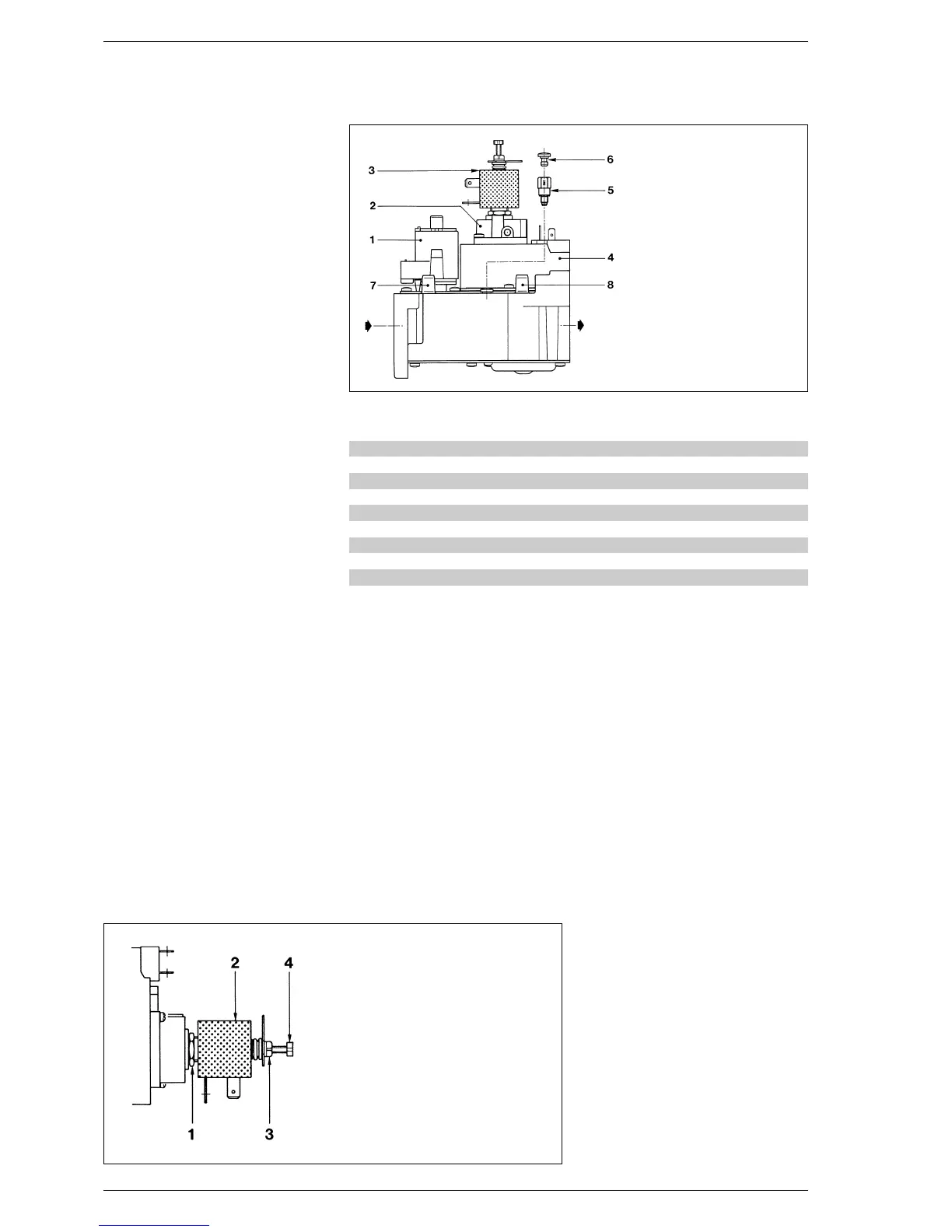

To set the maximum pressure, pro-

ceed as follows (fig. 11):

– connect the pressure column or a

pressure gauge to the pressure

intake located on the burner

manifold;

– unscrew the screw (4) completely;

– set the knob of the thermostat to

the maximum value;

– supply electric power to the boiler;

– loosen the locknut (1) and turn the

connection (3):

to reduce the pressure, turn the

connection counterclockwise; to

increase the pressure, turn the con-

nection clockwise;

– tighten the locknut (1);

– operate the main switch a number

of times, making sure that the maxi-

mum pressure corresponds to the

values given in Table 1.

4.2.2 Reduced pressure

adjustment

To set the reduced pressure, proceed

as follows (fig. 11):

–

deactivate the coil (2) electric supply;

– switch on the boiler and after a

short period of operation at nominal

output, turn the thermostat knob

slowly towards the minimum posi-

tion until you hear the click of the

first contact of the thermostat;

– leave the knob in that position and,

turning the screw (4), seek the mini-

mum pressure value according to

Table 1 for the gas in question: to

reduce the pressure, turn the

screw counterclockwise; to increase

the pressure, turn the screw

clockwise;

– restore electric power to the coil;

– operate the main switch a number

of times, making sure that the mini-

mum pressure corresponds to the

value given in Table 1.

4.3 GAS CONVERSION

To convert to butane gas (G30) or pro-

pane gas (G31), the main nozzles must

be replaced with another supplied in

the boiler gas conversion kit and apply

4 USE AND MAINTENANCE

KEY

1 EV1 coil

2 Pressure regulator

3 Coil assembly

4 EV2 coil

5 LPG adaptor

6 Plastic cap

7 Pressure inlet upstream

8 Pressure inlet

downstream

Fig. 10

70 Mk.II 80 Mk.II 90 Mk.II 100 Mk.II

Methane - G20

Burner max. pressure mbar 9.3 9.1 9.3 9.3

Burner min. pressure mbar 4.5 4.6 4.7 4.7

Butane - G30

Burner max. pressure mbar 25.2 25.4 25.1 25.1

Burner min. pressure mbar 12.2 12.3 12.0 12.5

Propane - G31

Burner max. pressure mbar 32.6 30.2 30.0 32.7

Burner min. pressure mbar 16.4 16.1 15.6 16.6

TABLE 1

LEYENDA

1 Locknut M13

2 Coil

3 Max. press. adjust. connection

4 Min. pressure adjust. screw

Fig. 11

Loading...

Loading...