2.8 ø 80 SEPARATE PIPES

INSTALLATION

When installing the pipes, follow closely the

requirements of the current standards, as

well as the following practical indications:

– With direct intake from outside, when

the pipe is longer than 1 m, you are rec-

ommended to insulate the piping so as

to prevent formation of dew on the out-

side of the piping during certain periods

of the year.

–

With the outlet pipe outside the building or

in cold indoor environments, insulation is

necessary to prevent burner failure while

starting. In such cases, provide for a con-

densate-collector system on the piping.

–

If a segment of the flue passes through a

flammable wall, this segment must be

insulated with a 30 mm thick glass wool

pipe insulator, with a density of 50 kg/m

3

.

The maximum overall length of the intake

and exhaust ducts depends on the head

losses of the single fittings installed and

must not exceed than 6,00 mm H

2

O.

During installation use only original SIME

accessories and make sure that the con-

nection is carried out properly, as indicated

in the accessory instructions.

For head losses in the fittings, refer to

Table 1.

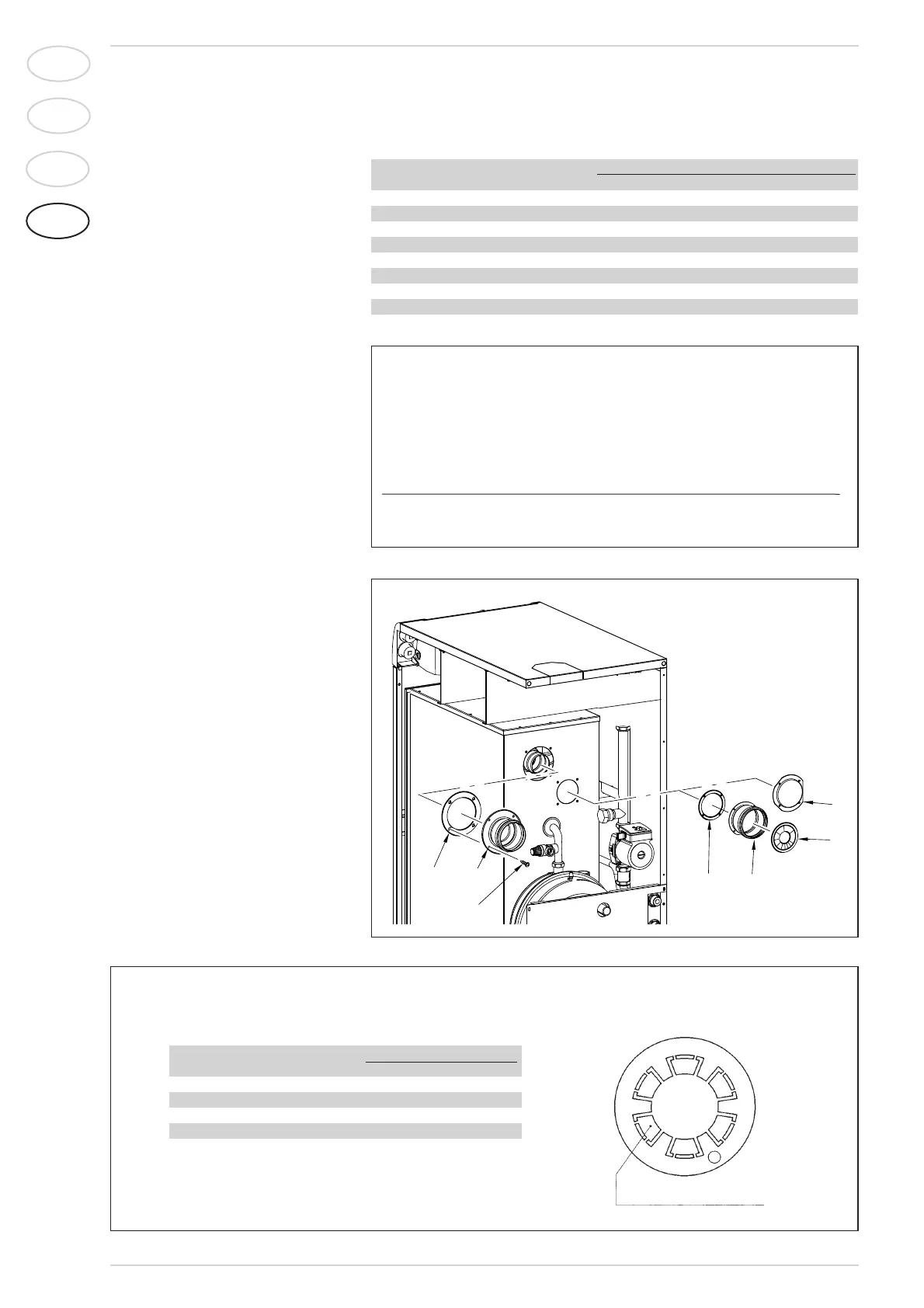

2.8.1 Separate flue kit (fig. 4)

The required intake diaphragm is supplied

with the separate duct kit code 8089905,

according to the maximum load allowed in

both ducts, as indicated in fig. 4/a.

2.8.2 Outlet systems

The diagrams in fig. 5 illustrate a number

of examples of different types of separate

outlets.

40

IT

ES

PT

GB

Fig. 4/a

Fig. 4

Example of allowable installation calculation in that the sum of the head losses of the

single fittings is less than 6,00 mm H

2

O:

Intake Outlet

6 meter horizontal pipe ø 80 x 0,20 1,20 –

6 meter horizontal pipe ø 80 x 0,40 – 2,40

n° 2 90° elbows ø 80 x 0,30 0,60 –

n° 2 90° elbows ø 80 x 0,50 – 1,00

n° 1 terminal ø 80 0,10 0,40

Total head loss 1,90 + 3,80 = 5,7 mm H

2

O

The intake diaphragm is to be removed with this maximum loss of load.

TABLE 1

Accessories ø 80 Load loss (mm H

2O)

Intake Outlet Roof out. Intake

90° elbow MF 0,30 0,50 –

45° elbow MF 0,20 0,40 –

Extension L. 1000 (horizontal) 0,20 0,40 –

Extension L. 1000 (vertical) 0,30 0,30 –

Outlet terminal – 0,40 –

Intake terminal 0,10 – –

Manifold 0,30 – –

Roof outlet terminal L. 1390 – – 0,60

Tee condensation outlet – 1,10 –

KEY

1 Blank flange

2 Outlet flange

3 Screw

4 Sponge sheath ø 125/95

5 Intake collar

6 Intake diaphragm

7 Sponge sheath ø 100/78

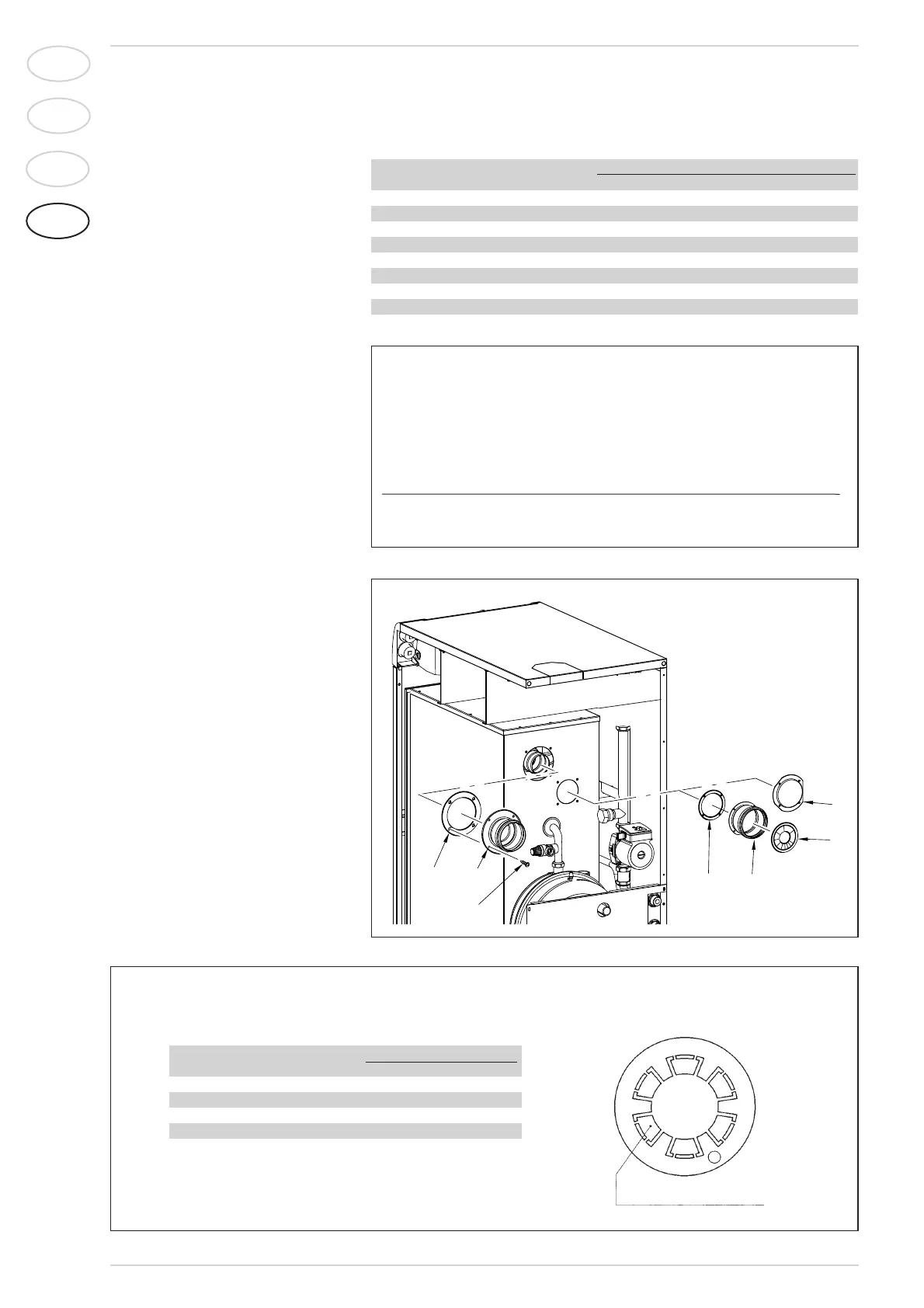

N° diaphragm sectors to remove Total load loss

mm H2OPa

1 0 ÷ 1 0 ÷ 9,8

3 1 ÷ 2 9,8 ÷ 19,6

4 2 ÷ 3 19,6 ÷ 29,4

6 3 ÷ 4 29,4 ÷ 39,2

Remove the diaphragm 4 ÷ 6 39,2 ÷ 58,8

DIAPHRAGM SECTOR

Loading...

Loading...